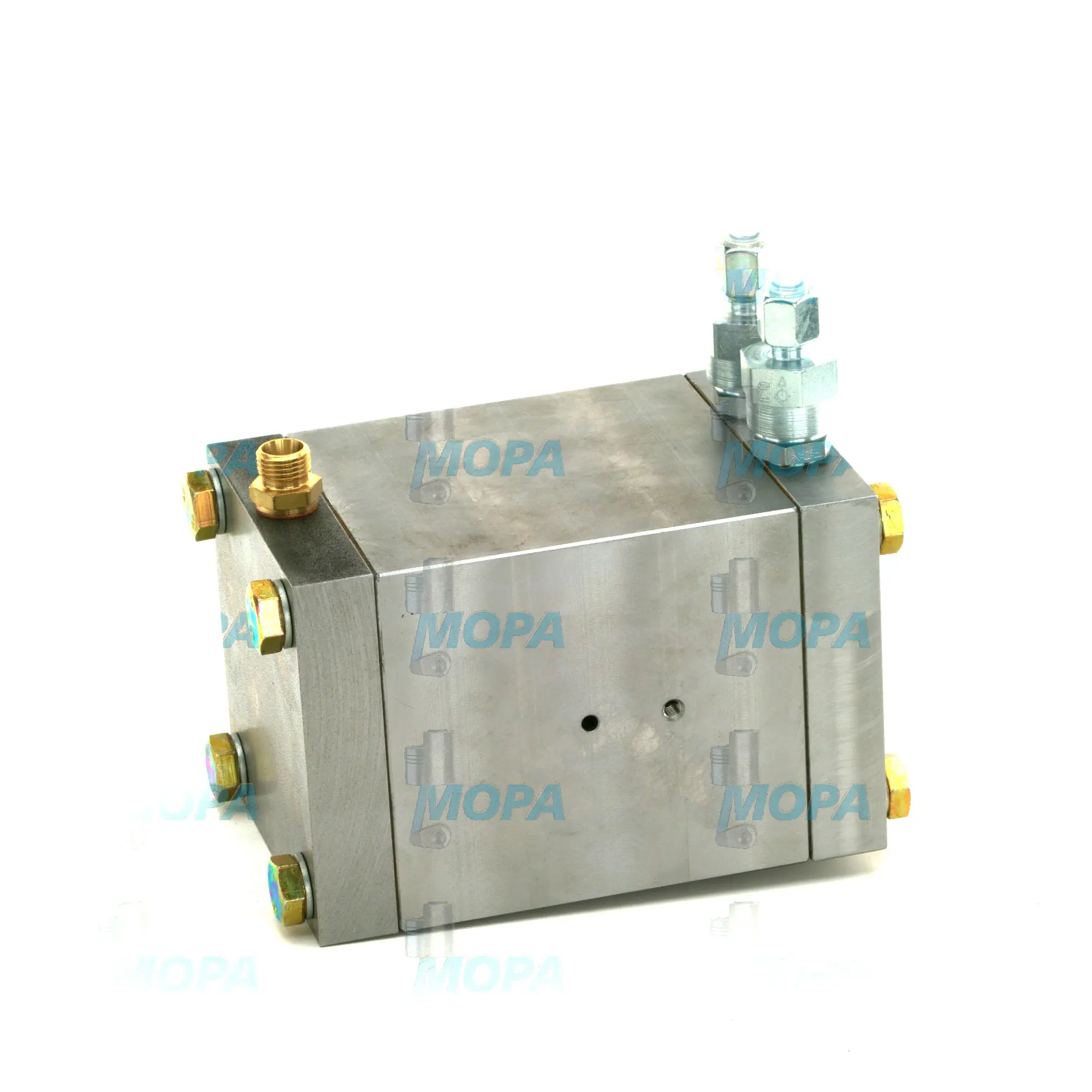

BOOSTER/SERVO UNIT – Air supply and compressed air for diesel and gas engines

Air supply and compressed air form a dedicated system category that feeds, conditions, stores, and distributes the air required for combustion, starting, and actuation on industrial, power-generation, and marine engines. This category spans intake filtration, turbocharging, charge-air cooling, compressors, receivers, dryers, regulators, valves, and pneumatic actuators such as the BOOSTER/SERVO UNIT that convert air energy into precise mechanical motion. In modern diesel and gas engines, dependable air handling is indispensable for efficiency, emissions stability, and safe operation across all loads and ambient conditions.

On marine engine applications, air supply and compressed air must withstand salt-laden atmospheres, variable fuel qualities, and long service intervals. In stationary power, reliability under continuous duty is crucial. Across both environments, the BOOSTER/SERVO UNIT integrates into the compressed-air control loop, amplifying pilot signals to position fuel racks, turbo bypasses, inlet shutters, or other air-handling components with repeatable accuracy. As a result, air systems are not an auxiliary afterthought—they are core engine subsystems that directly influence power density, response, and lifecycle cost.

Technical function of air supply and compressed air with a BOOSTER/SERVO UNIT in marine and diesel engines

Intake and charge air: Engine performance begins with clean, pressurized intake air. Filtration protects compressors and turbochargers from particulate ingress, while turbocharging and charge-air cooling increase oxygen density to improve specific fuel consumption and reduce exhaust temperatures. Properly managed air mass flow stabilizes combustion in diesel engines and maintains the correct lambda for gas engines.

Compressed-air generation and storage: Shaft- or motor-driven compressors feed air receivers typically at 30 bar for starting systems and around 6–10 bar for control air. Dryers and coalescing filters lower dew point and remove oil aerosols to protect seals and spools in downstream equipment. Safety devices—relief valves, non-return valves, and bursting discs—safeguard the plant.

Actuation and control via BOOSTER/SERVO UNIT: In control circuits, a BOOSTER/SERVO UNIT for marine engine or diesel engine applications uses a low-energy pilot input to modulate a higher-force pneumatic output. Inside the unit, precision spools, diaphragms, or pistons translate the pilot signal into linear or rotary motion, often with integral feedback to ensure position accuracy. This makes the BOOSTER/SERVO UNIT OEM parts interface ideal for governing fuel racks, modulating wastegates, operating air-start distributor timing, or driving emergency shutoff dampers. With clean, dry control air, response is fast, hysteresis is minimized, and the actuator delivers stable control even during rapid load changes.

Key characteristics and advantages of air supply and compressed air

· Stable intake mass flow enhances power and lowers fuel consumption.

· Clean, dry control air protects valves, spools, and BOOSTER/SERVO UNIT seals.

· Correct charge-air temperature and pressure curb NOx and smoke formation.

· Dedicated starting air at up to 30 bar ensures reliable cranking and repeat starts.

· Precision regulators and accumulators reduce pulsation in control loops.

· Fast, repeatable actuation improves turbo and fuel system coordination.

· Corrosion-resistant materials extend service intervals in marine environments.

· Integrated safety devices reduce the risk of overpressure and backflow.

Why air supply and compressed air are critical for engine reliability and service life

When air systems drift out of specification, the engine reveals it immediately. Intake restriction from clogged filters, fouled charge-air coolers, or leaking hoses reduces oxygen availability, driving up exhaust temperatures and brake-specific fuel consumption. In severe cases, turbocharger surge or compressor stall can occur, risking mechanical damage. On gas engines, air–fuel ratio errors lead to misfire, detonation margins closing, and unplanned shutdowns.

In the compressed-air plant, contamination and moisture cause sticking valves, actuator lag, and corrosion in lines and receivers. A drifting or leaking BOOSTER/SERVO UNIT in a diesel engine can present as hunting at idle, slow response to load steps, or unstable speed control under sea states—classic symptoms of internal leakage, worn diaphragms, or degraded seals. For starting systems, insufficient receiver pressure, faulty start valves, or water carryover results in extended cranking, hot starts, or failure to start—an unacceptable outcome for vessels under class or for engines on black-start duty in power plants.

Advantages of OEM spare parts suitable for air supply and compressed air

Using OEM spare parts suitable for air supply and compressed air ensures that flow coefficients, valve characteristics, elastomer compounds, and surface finishes meet the exact specifications the engine and pneumatic system were calibrated on. That fidelity preserves combustion stability, actuator response, and emissions compliance across the operating map.

Compared with generic replacements, OEM spare parts for a BOOSTER/SERVO UNIT and related assemblies deliver consistent dimensions and material properties that matter under cyclic pressure and vibration: nitrile or FKM seal selection matched to oil aerosol content and temperature, spring rates tuned for precise hysteresis, and corrosion-resistant housings for saline environments. Components are validated for endurance and pressure cycling, reducing unplanned downtime and cumulative wear on adjacent equipment like governors, turbochargers, and air starters.

From a budget and lifecycle perspective, the right OEM spare parts reduce fuel penalties from air-side inefficiencies, cut troubleshooting time thanks to predictable behavior, and mitigate risks during class surveys or emissions audits. Traceable, engine-specific compatibility minimizes rework and ensures that service intervals and maintenance plans remain on schedule.

BOOSTER/SERVO UNIT focus: performance in marine engine and diesel engine control

In practice, a properly calibrated BOOSTER/SERVO UNIT diesel engine actuator closes the loop between the governor signal and air-side hardware. Response times measured in tens of milliseconds enable smooth load acceptance, while tight deadband control keeps speed ripple low. When integrated with high-quality pneumatic conditioning—3 µm filtration and low dew point control air—internal wear is reduced, and the servo maintains setpoint accuracy over many thousands of cycles. Selecting OEM parts for the BOOSTER/SERVO UNIT and its service kits preserves that performance throughout overhaul intervals.

MOPA: fast, secure supply of OEM parts for air supply and compressed air

MOPA is an experienced partner for OEM spare parts in the Air supply and compressed air category, including the BOOSTER/SERVO UNIT for marine engine and diesel engine applications. Customers rely on rapid quotations, short lead times, and rigorously vetted quality across compressors, dryers, valves, receivers, regulators, and pneumatic actuators. Logistics are streamlined for shipboard and power-plant realities: consolidated shipments, export documentation, and traceable part numbers help keep maintenance windows tight and predictable.

From single critical items to full overhauls, MOPA supports technical decision-makers with part identification, specification matching, and proactive recommendations to prevent recurrence of air-side faults. The result is speed, quality, and security in the global trade of OEM parts for diesel and gas engines.

Conclusion: Air supply and compressed air with a BOOSTER/SERVO UNIT

Air supply and compressed air systems—anchored by precise devices like the BOOSTER/SERVO UNIT—are fundamental to engine performance, safety, and uptime. Selecting OEM spare parts suitable for this category sustains efficiency, stabilizes control, and protects budgets by reducing failures and fuel penalties. With MOPA as a partner, operators secure the right parts quickly and confidently to keep diesel and gas engines operating at their best.