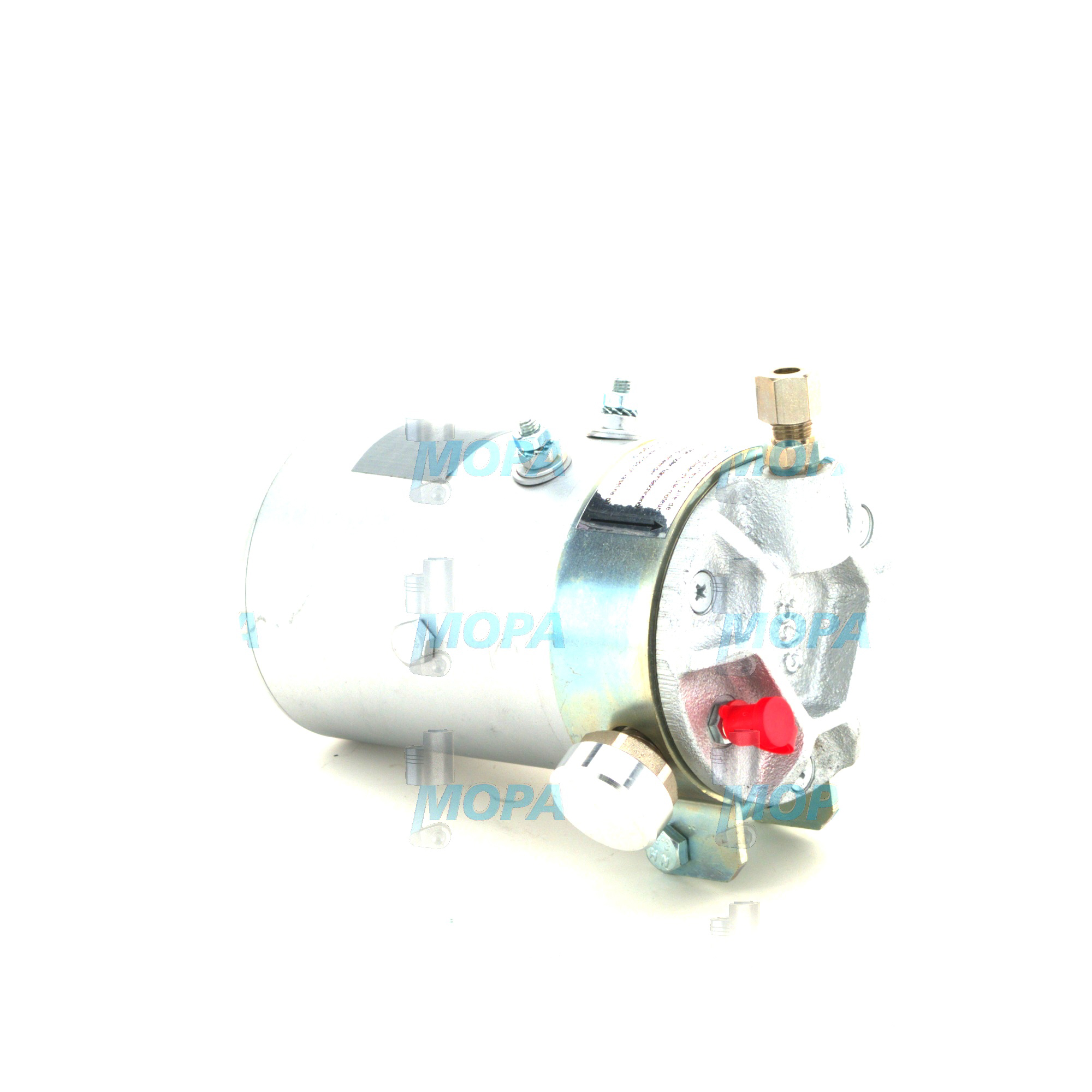

COMPRESSOR air supply and compressed air

Air supply and compressed air form a critical category of engine components that ensure clean induction air, dependable starting, and reliable control functions. In diesel and gas engines—especially in marine engine applications—this category covers the entire path from intake filtration and compression to drying, cooling, storage, and distribution. At its heart stands the COMPRESSOR, which raises air pressure for starting systems, instrument/control consumers, and, in some configurations, for charge-air support. Without robust, well-maintained air supply and compressed air equipment, no engine can deliver consistent power, efficiency, or safety.

In practice, “air supply and compressed air” includes the COMPRESSOR, air receivers, dryers, filters, separators, coolers, pressure control valves, non-return and safety valves, manifolds, hoses, monitoring sensors, and associated fittings. Together, these elements deliver the pressure and air quality that diesel engine and gas engine systems require to ignite fuel cleanly, start reliably, actuate automation, and protect key assemblies from contamination and corrosion. For shipowners and plant operators, the health of this category directly translates into uptime, fuel economy, compliance, and lifecycle cost.

Technical function of air supply and compressed air with COMPRESSOR in diesel and marine engine systems

The COMPRESSOR is the prime mover of compressed air. In a marine engine, it typically feeds two essential subsystems: start air and control (instrument) air. Start-air systems store high-pressure air—commonly 25–30 bar—in air receivers and deliver it via starting valves to crank the engine. Control-air systems distribute stable, clean air—typically 6–8 bar—to actuators, clutches, fuel racks, gas admission valves, pneumatic starters, and safety circuits.

Upstream, intake filtration removes particulates; downstream, intercoolers and aftercoolers reduce discharge temperatures to protect seals and lubricants, while dryers (refrigerant or desiccant) lower the dew point to prevent water accumulation in lines. Oil separators and coalescing filters minimize oil carryover from the COMPRESSOR, protecting solenoids, proportional valves, and sensitive instruments. Pressure regulators and non-return valves stabilize flow and protect receivers, and well-placed relief and safety valves preserve system integrity during transients. In diesel engine service, charge-air temperature reduction via coolers improves volumetric efficiency; in gas engines, stable, clean control air is crucial for precise lambda control and misfire prevention.

Where low-speed two-stroke marine engines rely on turbochargers for scavenging, auxiliary blowers and the COMPRESSOR still provide start air and instrument air, keeping the engine operable at low load and during starts. On medium-speed engines, a COMPRESSOR may also support pneumatic clutches and gearbox actuation. For procurement, it is common to specify COMPRESSOR marine engine packages by duty cycle, free air delivery (FAD), final pressure, dew point, allowable oil carryover, and noise/emissions compliance, alongside materials and sealing compatible with salty, humid ambient conditions.

Key characteristics and advantages at a glance

· Stable start-air pressure across load changes.

· Clean, dry instrument air to ISO 8573 classes.

· Efficient cooling for lower discharge temperatures.

· Low oil carryover to protect valves and sensors.

· Robust corrosion-resistant components for marine duty.

· Reliable non-return and safety devices to protect receivers.

· Easy access to filters and drains for quick maintenance.

· Clear instrumentation for pressure, temperature, and dew point.

Importance for engine operation and service life

Air supply and compressed air are foundational to engine reliability. Insufficient start-air pressure prolongs crank time, accelerates starter wear, and can prevent a timely restart after blackout scenarios. Wet control air leads to corrosion, ice formation, and sticking of precision valves, causing erratic fuel control, clutch malfunctions, or unintended trips. Excess oil carryover fouls charge-air coolers and pneumatic components, reducing heat transfer, raising exhaust temperatures, and increasing fuel consumption. Leaks and poorly regulated systems drive COMPRESSOR overrun, elevating operating temperature, shortening maintenance intervals, and accelerating bearing and seal degradation.

In gas engines, unstable control air can disrupt gas admission, compromise combustion stability, and force derating. On diesel engines, poor filtration draws abrasive particles into the COMPRESSOR and downstream equipment, increasing wear. Over time, these issues shorten component service life, increase unplanned downtime, and raise the total cost of ownership. Conversely, a clean, dry, and pressure-stable air network sustains predictable combustion, supports safe automation, and preserves the health of turbochargers, coolers, valves, and cylinders.

Advantages of OEM spare parts suitable for air supply and compressed air

Using OEM spare parts suitable for this category ensures that COMPRESSOR diesel engine and marine engine systems meet the performance and safety thresholds they were engineered for. Tolerances on rotors, pistons, and valve plates directly influence volumetric efficiency and heat generation. Seals, desiccants, and filter media specified by the engine maker preserve dew point, filtration efficiency, and oil carryover limits over the stated service life. Pressure-bearing items—receivers, fittings, and safety devices—are produced to materials and test regimes that maintain compliance and reduce risk.

From a budget perspective, OEM spare parts minimize rework, align with recommended maintenance intervals, and protect surrounding assets such as charge-air coolers and actuators. They integrate seamlessly—dimensionally and functionally—with existing COMPRESSOR OEM parts, preserving calibration and monitoring baselines. The result is predictable downtime planning, consistent energy consumption per Nm³ of compressed air, and extended service life of the entire air network.

COMPRESSOR OEM parts: performance, reliability, and lifecycle benefits

Spec-correct valves, separators, and dryers maintain the targeted dew point and particulate class, cutting corrosion and blockage events. Precision bearings and gaskets hold clearances under thermal load, limiting leakage and backflow. Correctly rated non-return and safety valves maintain system protection during rapid starts and load changes. Together, these choices secure performance, reliability, and a favorable lifecycle cost profile without compromising safety margins.

MOPA as a partner for COMPRESSOR and air supply OEM parts

MOPA is an experienced, reliable partner for OEM spare parts in the Air supply and compressed air category. Buyers benefit from fast quotation and delivery, proven quality, and secure, traceable transactions for diesel and gas engines. MOPA’s network covers COMPRESSOR marine engine assemblies and peripheral components—filters, dryers, receivers, valves, and sensors—matched to engine-maker specifications.

With stock availability on critical items, pre-shipment inspections, and documentation that supports class and audit requirements, MOPA helps reduce downtime and procurement risk. Technical support aligns parts selection with your duty cycle, ambient conditions, and maintenance strategy, ensuring that each component sustains the required pressure, dew point, and cleanliness targets.

Conclusion

Air supply and compressed air are indispensable to safe starting, clean combustion, and dependable automation—functions driven by a properly configured and maintained COMPRESSOR system. Selecting OEM spare parts suitable for this category safeguards performance, reliability, budget, and service life across diesel and gas engines.