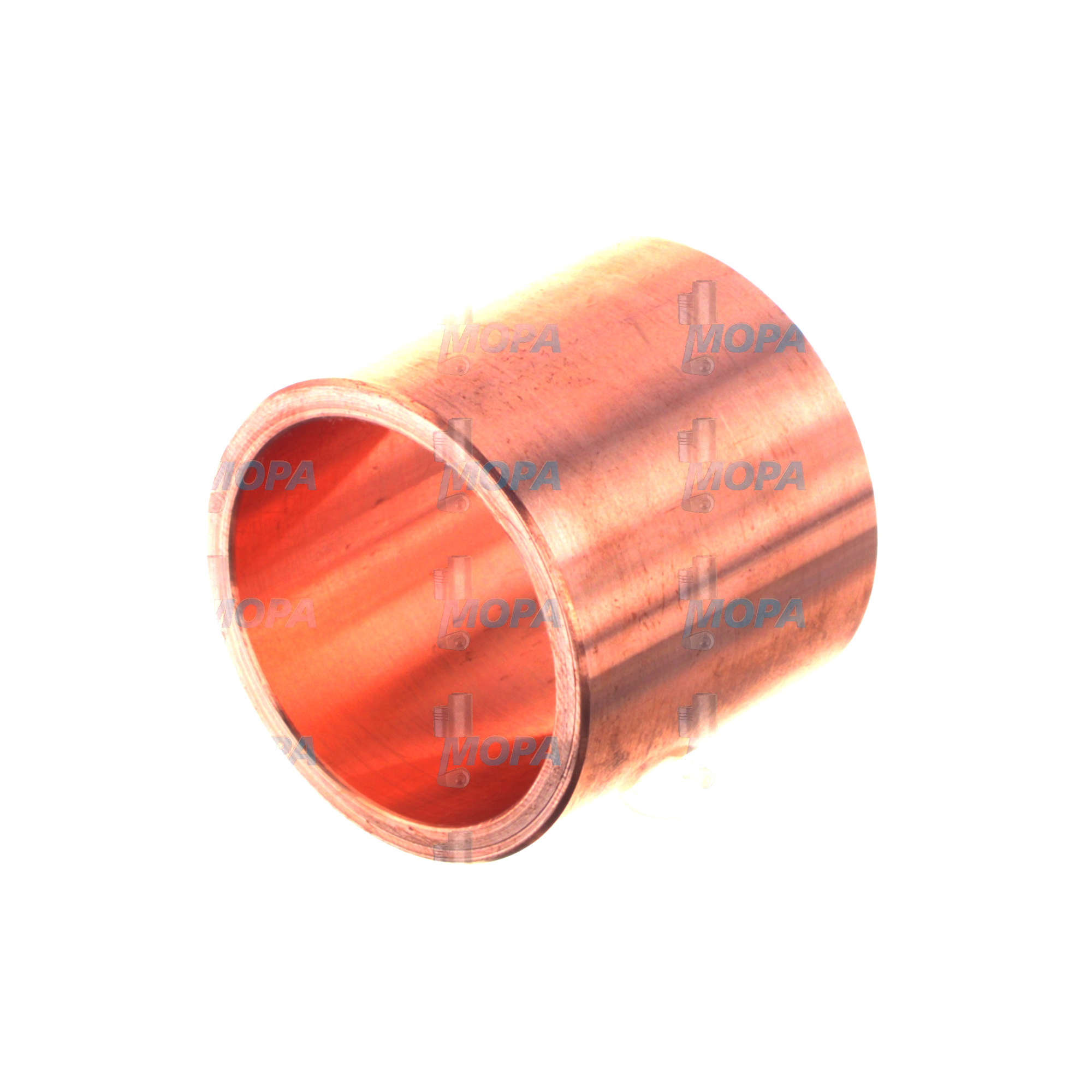

BEARING BUSHING Bearings for Demanding Diesel and Marine Engines

Bearings are precision-engineered components that support rotating and oscillating shafts within engines. In heavy-duty diesel and marine engines, they carry substantial radial and axial loads while maintaining stable running clearances and a continuous lubricating film. The category includes main bearings, connecting rod bearings, camshaft bearings, and thrust bearings—often implemented as plain-shell inserts or a BEARING BUSHING that fits into a housing bore. By minimizing metal-to-metal contact and controlling friction and heat, bearings protect critical engine parts, maintain alignment, and enable efficient power transmission over long service intervals.

Technical function of Bearings and BEARING BUSHING in diesel and marine engines

Engine bearings operate predominantly as hydrodynamic plain bearings. When the crankshaft or camshaft rotates, oil is drawn into the converging clearance between journal and BEARING BUSHING, forming a load-bearing wedge of pressurized lubricant. This oil film separates surfaces, reduces wear, and dampens vibration. Correct bearing geometry—crush, eccentricity, and spread—ensures tight fitment in the housing and stable oil film formation, even under fluctuating loads typical of propulsion duty and generator sets.

Material systems are selected to balance load capacity with conformability and embeddability. Tri-metal designs typically combine a steel backing for stiffness, a copper-lead intermediate for fatigue resistance, and a soft overlay (e.g., tin-based) that accommodates minor misalignments and traps small hard particles. Bi-metal aluminum alloys are often used for high-speed applications with excellent corrosion resistance and thermal conductivity. Oil grooves, supply holes, and edge chamfers are engineered to control flow, prevent starvation, and mitigate edge loading under crankshaft flex and thermal growth.

In practice, main bearings stabilize the crankshaft, connecting rod bearings manage alternating combustion loads, camshaft bearings ensure precise valve timing, and thrust bearings control axial movement to protect gear trains and couplings. In each case, a correctly specified BEARING BUSHING for a marine engine or diesel engine secures consistent oil pressure, smooth rotation, and predictable wear behaviour—key to efficiency and low specific fuel consumption.

- · Hydrodynamic oil film separates metal surfaces.

- · Precision geometry (crush, eccentricity) stabilizes clearances.

- · Optimized overlays improve conformability and embeddability.

- · Controlled oil grooves and holes prevent starvation.

- · High fatigue strength resists cyclic combustion loads.

- · Thermal conductivity manages heat at high rpm and load.

- · Axial control via thrust bearings protects gear trains.

- · BEARING BUSHING options tailored for marine engine duty.

Design details that drive performance with OEM parts

Seemingly small details have outsized effects on bearing life. Surface finish (Ra/Rz) of both journal and BEARING BUSHING dictates oil film stability and run-in behaviour. Correct housing bore roundness and crush height prevent micro-movement and fretting. Overlay thickness and lead content influence seizure resistance under marginal lubrication. Eccentricity is tuned to maintain film thickness where peak load occurs, while edge relief mitigates localized contact from shaft deflection. Specifying BEARING BUSHING OEM parts with validated metallurgy and finished dimensions ensures these parameters are consistent engine-wide.

Why Bearings are critical for reliable engine operation

Because bearings sit at the heart of every rotating system, their condition directly determines reliability and service life. Excessive clearance leads to low oil pressure, vibration, and piston slap; insufficient clearance risks heat buildup and seizure. Wear or fatigue in a BEARING BUSHING can propagate to journal scoring, misalignment of the crank train, and increased fuel consumption due to higher friction losses. Cavitation damage may occur in high-load marine engine main bearings if oil supply or damping is inadequate. Contamination accelerates overlay removal and can cause catastrophic wipe-out events, especially at cold starts.

Early symptoms—such as metal in filters, fluctuating oil pressure, or elevated bearing temperature—should trigger inspection and dimensional checks. Proactive replacement with correctly matched bearings preserves shaft integrity and prevents secondary damage to connecting rods, crankshafts, and camshafts. Reliable bearings directly translate into smoother operation, stable emissions compliance, and predictable maintenance planning.

Advantages of OEM spare parts suitable for Bearings and BEARING BUSHING

Selecting OEM spare parts suitable for your engine’s bearings ensures that critical tolerances, materials, and surface finishes match the engine maker’s specifications. This alignment is fundamental to performance, reliability, budget control, and service life across diesel and gas platforms.

Key advantages include:

- · Consistent metallurgy and overlay systems for high fatigue strength.

- · Exact geometry for crush height, eccentricity, and thrust faces.

- · Correct oil hole and groove alignment for stable lubrication.

- · Engineered surface finish for fast, safe run-in and long life.

- · Dimensional compatibility with housing bores and journal sizes.

- · Proven performance history in specific engine families.

- · Reduced downtime through predictable fit and function.

- · Lower total cost of ownership via extended service intervals.

When a BEARING BUSHING OEM parts set is selected precisely by engine model, serial range, and bearing grade, it maintains design oil clearances and preserves the hydrodynamic film under real-world load cycles. The result is dependable operation with minimized risk of secondary damage and unplanned stoppages.

MOPA as your partner for OEM spare parts Bearings and BEARING BUSHING

MOPA is an experienced and reliable partner for OEM spare parts in the Bearings category. We source and supply BEARING BUSHING solutions for diesel and gas engines used in marine propulsion, auxiliary power, and industrial applications. Our focus is speed, quality, and security throughout the transaction—rapid identification by part number and engine model, technical verification of dimensions and material systems, and streamlined logistics to minimize vessel or plant downtime.

Customers value MOPA for responsive quoting, traceable supply chains, and careful packaging that protects precision surfaces. Whether you require main bearings for a large-bore two-stroke marine engine or camshaft bearings for a medium-speed generator set, we provide OEM parts that align with the engine’s intended load profile and maintenance philosophy.

Conclusion: BEARING BUSHING bearings protect performance and uptime

Bearings—and especially a correctly specified BEARING BUSHING—are fundamental to engine efficiency, safety, and longevity. By maintaining stable lubrication and precise running clearances, they safeguard the crank train and keep fuel and maintenance costs in check.

OEM spare parts suitable for Bearings provide the dimensional accuracy and material integrity needed for dependable service in diesel and marine engines. Partner with MOPA to secure the right components quickly and confidently.