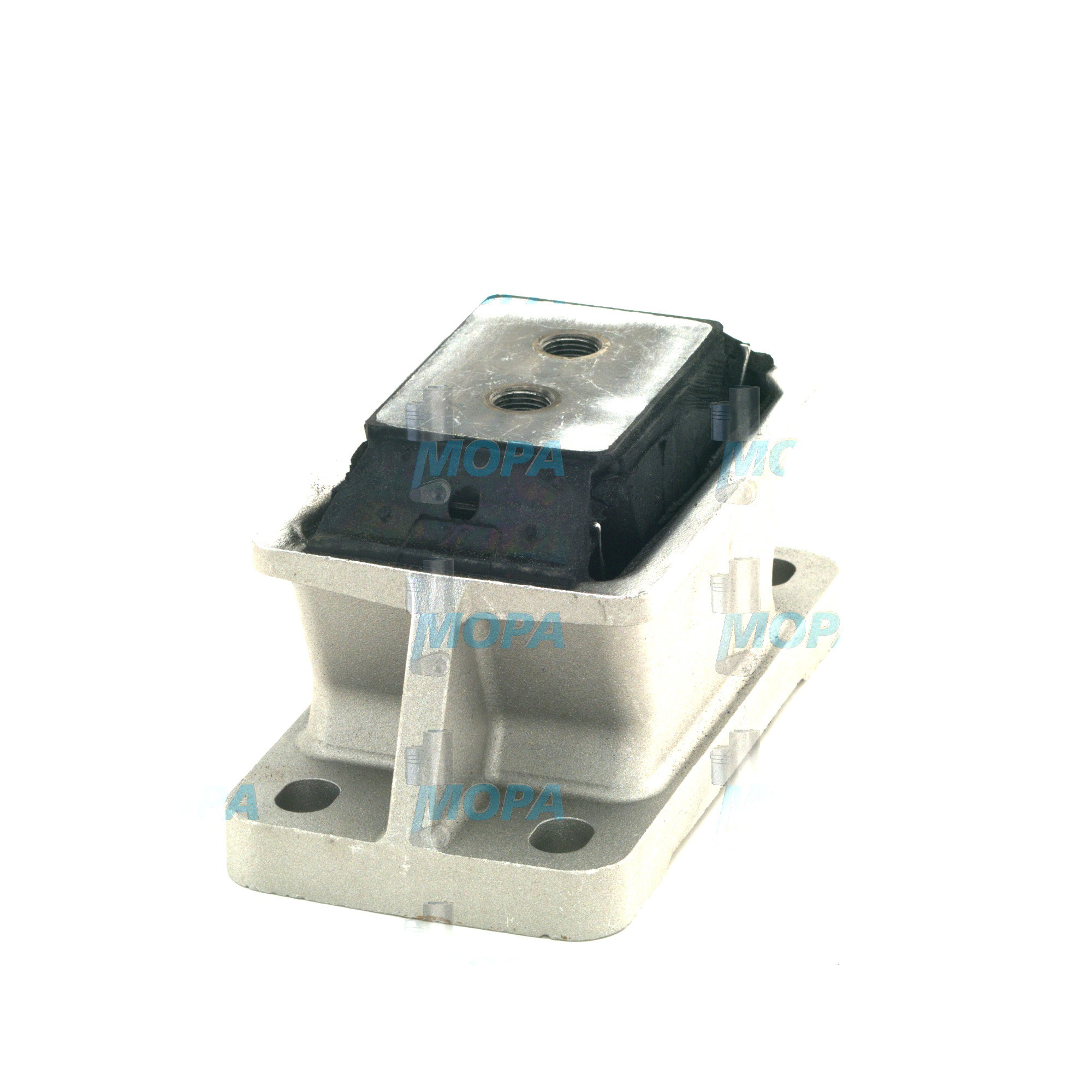

BONDED RUBBER MOUNTING and Bearings for marine and diesel engines

Bearings are precision engine components that support and guide rotating and oscillating parts while minimizing friction. In diesel and gas engines—whether propulsion units on a vessel or stationary power generation sets—bearings carry radial and axial loads in the crankshaft, connecting rods, camshafts, turbochargers, pumps, and alternators. Their job is fundamental: maintain accurate clearances under thermal and mechanical load, stabilize shafts, distribute forces evenly, and keep surfaces separated by a controlled oil film. Without properly specified and maintained bearings, no engine can deliver sustained performance, efficiency, or safety.

The article category Bearings includes plain (journal) bearings, big-end and main shells, thrust washers, crosshead bearings, small-end bushings, and rolling-element bearings for auxiliaries. Each type is tailored to operating conditions—load direction, speed, temperature, lubrication regime—and material pairing. In marine engine applications, bearing construction typically uses a steel backing with a copper-lead or aluminum-tin intermediate layer and a soft, conformable overlay (often a tin-based babbitt) that accommodates minor debris and misalignment. This stack-up balances fatigue strength with embeddability and conformability—critical for long life in harsh conditions.

Technical function of Bearings in engines – BONDED RUBBER MOUNTING marine engine context

Most crankshaft and connecting-rod bearings operate hydrodynamically. As the journal rotates, it drags oil into a converging wedge, generating pressure that centers the journal on a fluid film. Proper design sets diametral clearance (commonly 0.001–0.002 times journal diameter), crush and spread for housing retention, and precise oil-groove geometry to maintain film thickness. Surface finish on journals (often ≤ Ra 0.4 μm) and correct overlay thickness help avoid boundary contact, scuffing, and seizure during transients. Thrust bearings limit axial movement, protecting gear trains and turbocharger couplings, while rolling bearings in auxiliaries handle combined loads at high speeds with optimized cage designs and heat-treated races.

Vibration isolation and alignment stability are just as important. Correctly specified BONDED RUBBER MOUNTING marine engine solutions at the foundation reduce structure-borne vibration and prevent distortion of bearing housings. On a diesel engine, excessive vibration can disrupt oil wedge formation, cause edge loading, and accelerate fatigue spotting. Coordinating BONDED RUBBER MOUNTING OEM parts with the bearing specification preserves alignment, sustains oil film integrity, and lowers the risk of fretting at the bearing split line.

- · Low friction under hydrodynamic lubrication.

- · High load capacity for main, big-end, and crosshead locations.

- · Precise clearances for stable oil film and low wear.

- · Materials engineered for fatigue strength and embeddability.

- · Optimized oil grooves and holes for reliable lubrication.

- · Axial control via thrust bearings for drivetrain protection.

- · Thermal stability to manage start–stop and load cycles.

- · Compatibility with BONDED RUBBER MOUNTING diesel engine setups to reduce vibration-induced stress.

Importance of Bearings for engine reliability and service life – BONDED RUBBER MOUNTING synergy

Bearings are the first line of defense against mechanical loss and failure. When they maintain correct clearance and oil-film conditions, friction drops dramatically, parts run cooler, and journals remain protected from wear. Conversely, bearing degradation quickly cascades into serious issues: falling oil pressure, rising metal content in oil analysis (tin, lead, aluminum), elevated temperatures, knocking under load, and eventually spalling, wipe, or seizure. Debris from a failing bearing can damage the oil pump, clog jets, and destroy a crankshaft or turbocharger within minutes—resulting in unplanned downtime at sea or on site.

Misalignment from soft foot or foundation movement is a common root cause. This is where BONDED RUBBER MOUNTING diesel engine isolation interacts with bearing longevity. Stable, correctly rated mounts limit deflection under thrust and torque, keep couplings true, and minimize cyclic loads on bearing shells. The combined approach—clean lubrication, proper clearances, aligned housings, and tuned mounts—extends overhaul intervals and stabilizes lifecycle costs.

Advantages of OEM spare parts suitable for Bearings – performance, reliability, budget, service life with BONDED RUBBER MOUNTING OEM parts

Selecting OEM spare parts suitable for Bearings ensures the exact metallurgy, layer thicknesses, and geometry the engine was engineered around. That includes steel-back hardness, bonding integrity, copper-lead or aluminum-tin composition, overlay thickness, and anti-cavitation features—plus the precise crush, spread, dowel fit, and tang design required for housing retention. Dimensional tolerances down to microns preserve oil-film formation and help avoid mixed-lubrication contact during cold starts and load steps.

From a reliability and budget perspective, the benefits are direct: predictable load capacity, proven fatigue limits, and repeatable clearances reduce the risk of secondary damage and shorten installation time. Traceable production and batch consistency underpin condition-based maintenance and oil-analysis trending. Coordinating Bearings with BONDED RUBBER MOUNTING OEM parts ensures vibration isolation matches the engine’s dynamic signature, further protecting journals, bushings, and thrust faces. The result is sustained performance, fewer unscheduled stoppages, and optimized total cost of ownership across diesel and gas engines.

MOPA as your partner for OEM spare parts Bearings – speed, quality, and security in trade

MOPA supplies OEM spare parts suitable for Bearings for leading diesel and gas engine platforms, backed by fast response, technical clarity, and secure global logistics. Our team understands the nuances of bearing selection—shell grades, undersizes/oversizes, thrust segment geometry, and lubrication routing—and helps align specifications with your engine serial, load profile, and fuel type.

Why MOPA for BONDED RUBBER MOUNTING and Bearings in marine and diesel engines

We combine rapid quotation and dispatch with careful documentation, batch traceability, and seaworthy packaging that protects sensitive surfaces. Whether you need main and big-end shells, thrust washers, small-end bushes, or rolling bearings for auxiliaries—paired with BONDED RUBBER MOUNTING OEM parts for noise and vibration control—MOPA delivers speed, quality, and security so your equipment returns to service with confidence.

Conclusion – Bearings and BONDED RUBBER MOUNTING for dependable engine operation

Bearings are vital to engine efficiency and reliability, protecting critical shafts under heavy loads while maintaining friction control. Coordinated use of OEM spare parts suitable for Bearings—together with matched BONDED RUBBER MOUNTING solutions—safeguards alignment, oil-film stability, and long service life. Partner with MOPA to source the right parts quickly and keep your marine and diesel engines performing at their best.