CYLINDRICAL ROLLER BEARING solutions in Bearings for diesel and marine engines

Bearings are precision components that support rotating assemblies in engines, reduce friction, and keep shafts precisely aligned under heavy loads. Within the article category Bearings, you will find designs for main and auxiliary engine systems—from camshaft supports and gear trains to pumps, alternators, and turbocharger carriers. In these roles, the CYLINDRICAL ROLLER BEARING is a core element wherever high radial loads, tight tolerances, and continuous duty intersect. For shipowners, power plant operators, and maintenance planners, robust bearings are fundamental to dependable operation, predictable lifecycle costs, and safe performance at sea and on land.

Technical function of Bearings in heavy-duty engines

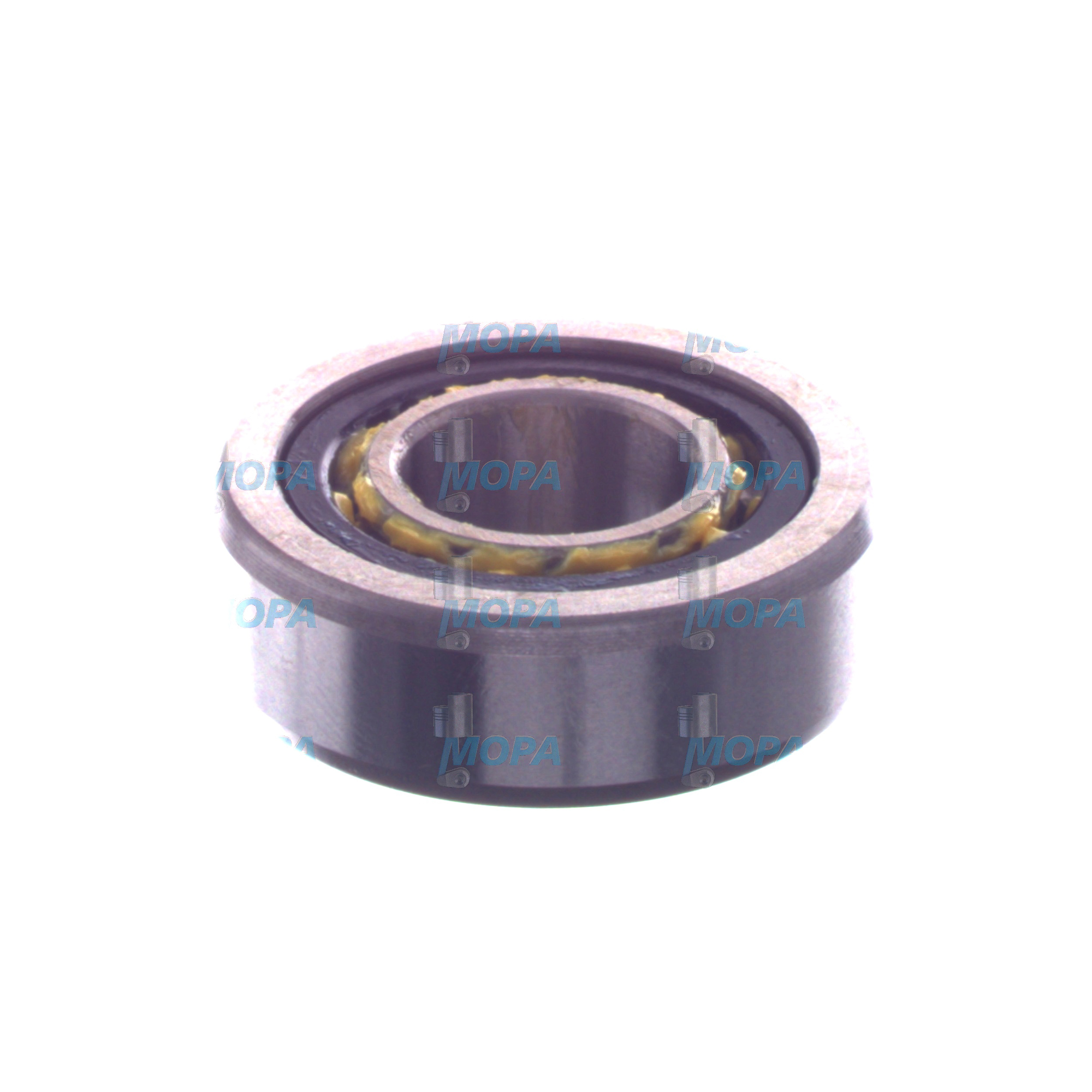

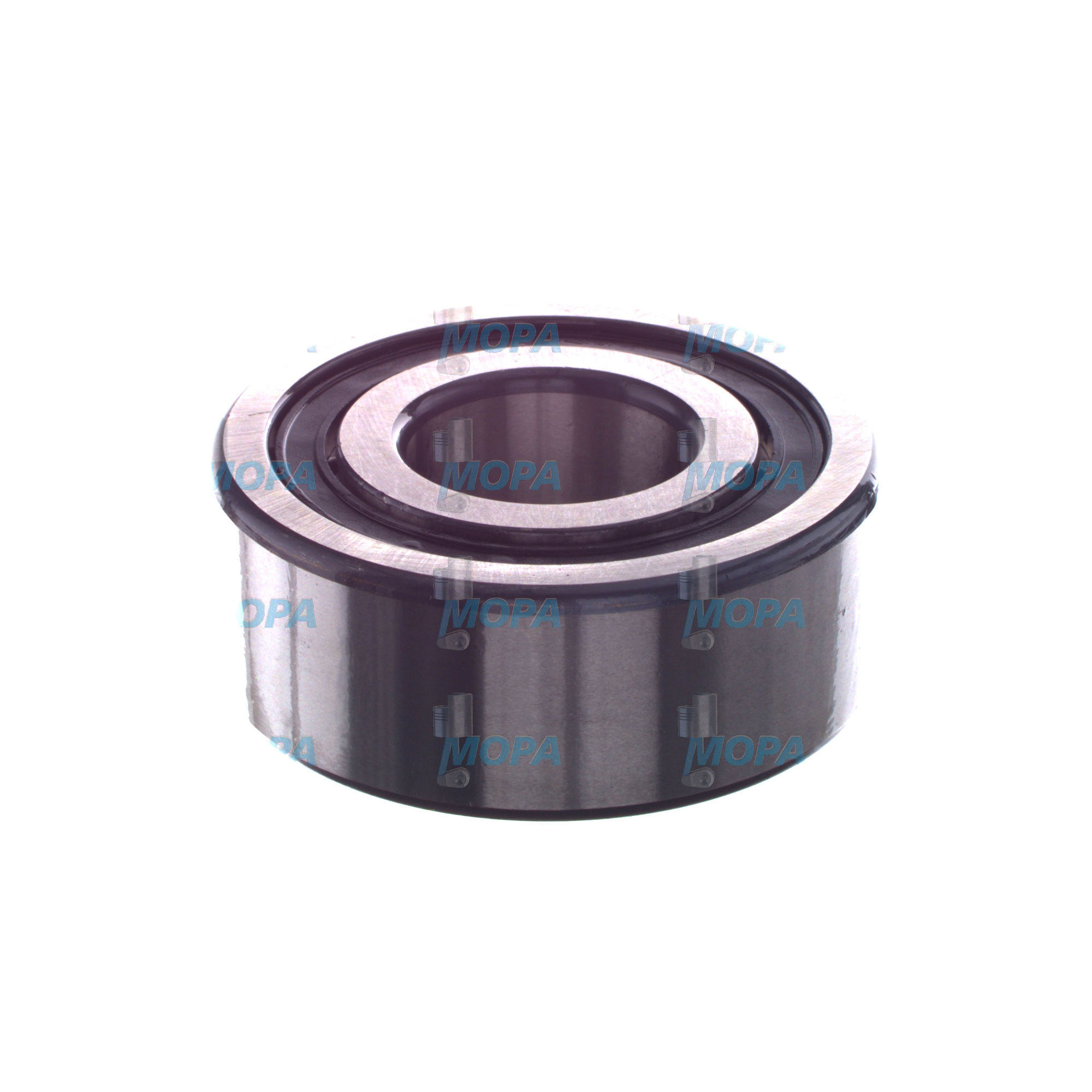

Engine bearings transform metal-to-metal contact into controlled rolling or sliding to minimize friction and wear. While crankshaft mains and big-end journals often rely on hydrodynamic plain bearings, many engine sub-systems require rolling-element designs. The CYLINDRICAL ROLLER BEARING uses line contact between rollers and raceways to carry very high radial loads with low friction. Its separable rings simplify mounting in confined housings, and cage designs (steel, brass, or polymer) manage roller spacing for high-speed stability. Correct internal clearance (e.g., C3 for elevated operating temperatures), precise fits, and clean lubrication are critical to ensure a stable oil film, low heat generation, and long service life.

In diesel and gas engines, cylindrical roller bearings commonly support camshafts, intermediate gear shafts, blower and compressor rotors, PTO gearboxes, alternators, and auxiliary equipment drives. In these locations, they must handle shock loads, start-stop cycles, and thermal expansion without losing alignment. Optimized microgeometry—crowned rollers, profiled raceways—distributes stress to prevent edge loading and reduce risks of scuffing and spalling. Sealed versions help keep contamination out in dusty or salty environments, while open designs with optimized lubrication grooves support higher speeds and effective heat dissipation.

CYLINDRICAL ROLLER BEARING marine engine and diesel engine applications

For a marine engine gear train, the CYLINDRICAL ROLLER BEARING maintains precise gear mesh under hull vibration and fluctuating torsional loads. In a high-speed diesel engine alternator drive, its low-friction rolling elements minimize power loss and temperature rise. When specified as CYLINDRICAL ROLLER BEARING OEM parts, the bearing geometry, heat treatment, and cage design align with the engine builder’s tolerances, ensuring consistency across fleets and reducing the need for on-site adjustments.

- · High radial load capacity from line contact rollers.

- · Low friction for efficient power transmission.

- · Tight dimensional tolerances for precise shaft alignment.

- · Separable rings for easier mounting and maintenance.

- · Cage options tailored to speed and load profiles.

- · Optimized roller/raceway geometry to reduce edge stresses.

- · Configurable internal clearances for thermal conditions.

- · Sealed or open designs to match lubrication strategies.

Why Bearings are crucial for engine reliability and service life

Bearings protect critical engine assets by stabilizing shafts, keeping backlash under control, and preventing heat buildup. When bearings perform as designed, gears remain quiet, timing stays accurate, and auxiliary systems deliver rated output with minimal losses. Conversely, worn or contaminated bearings can trigger a cascade of failures: misalignment in a camshaft train can offset valve timing, elevated friction increases fuel consumption, metal debris accelerates wear elsewhere, and excessive vibration can crack housings or damage seals.

Typical failure modes include pitting and flaking from rolling contact fatigue, cage fracture due to lubrication starvation, false brinelling during prolonged standstill with vibration, and fretting corrosion from micro-movement at fits. Root causes often trace to poor lubrication quality, incompatible clearances, improper fits, contamination ingress, or overloads outside design limits. Proactive measures—clean assembly practices, correct oil viscosity, filtered lube circuits, and periodic vibration and temperature trending—extend bearing life and safeguard engine availability.

Advantages of OEM spare parts suitable for Bearings

Choosing OEM spare parts suitable for Bearings provides a decisive edge in performance, reliability, budget control, and lifecycle. Dimensional consistency and controlled heat treatment deliver predictable running clearances and stable microstructure under engine temperatures. Surface finishes and roller profiles matched to the engine maker’s specifications keep contact stresses low, while traceable production and batch testing add confidence in repeatability across multiple overhauls.

For a CYLINDRICAL ROLLER BEARING, this alignment translates into lower friction losses in auxiliary drives, precise gear mesh retention over long intervals, and reduced risk of early spalling. The result is fewer unplanned stoppages and better fuel and lube oil economics—key drivers for total cost of ownership in fleet operations.

- · Consistent fit and clearance for predictable operation.

- · Proven metallurgy and heat treatment for durability.

- · Optimized geometry that protects against edge loading.

- · Reliable lead times and part traceability for planning.

- · Lower downtime through fast, correct replacements.

- · Better lifecycle economics through extended service intervals.

MOPA: your partner for OEM spare parts Bearings

MOPA is an experienced and reliable partner for OEM spare parts Bearings across diesel and gas engine platforms. We combine fast response with stringent quality processes and secure sourcing to keep vital equipment running—whether you operate a deep-sea vessel, a coastal fleet, or a power generation site. Our team supports you with technical identification, cross-references for CYLINDRICAL ROLLER BEARING selections, and documentation such as certificates of conformity to meet class and audit requirements.

With MOPA, purchasers and superintendents gain quick access to stocked items, efficient logistics, and transparent order handling. From single urgent line items to complete overhaul kits, we streamline procurement of OEM parts so maintenance teams can execute safely and on schedule.

Conclusion

Bearings—especially the CYLINDRICAL ROLLER BEARING in engine auxiliaries—are foundational to performance, efficiency, and safety. Selecting OEM spare parts suitable for Bearings preserves alignment, reduces friction losses, and extends service life, delivering reliable power and lower total operating costs.