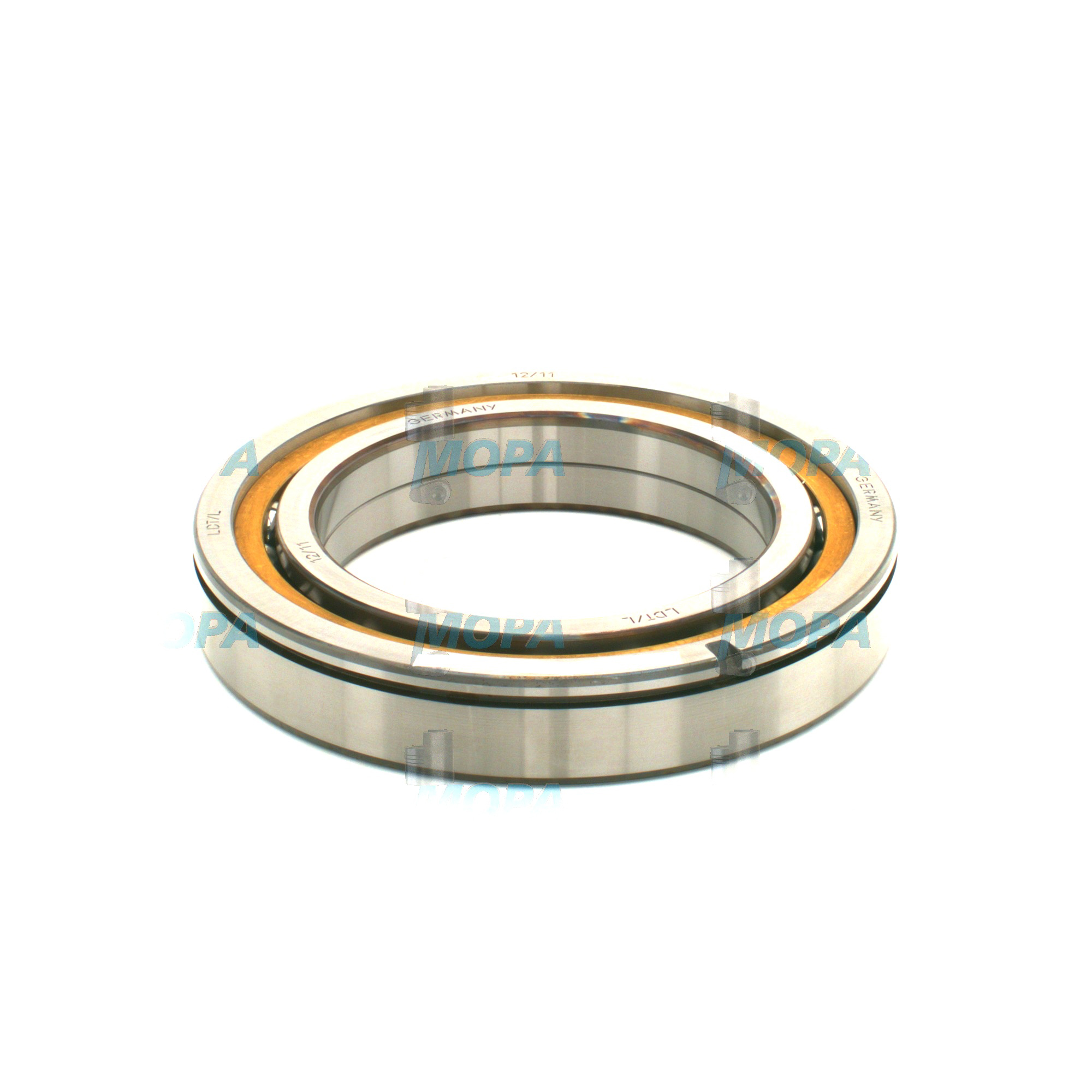

FOUR POINT CONTACT BEARING and Precision Bearings for Marine and Diesel Engines

Bearings are precision components that minimize friction, support rotating assemblies, and keep shafts precisely aligned under load. In engines, they are essential at every level: from crankshaft and camshaft supports to gear trains, pumps, turbochargers, alternators, and auxiliary equipment. The category spans rolling-element bearings (such as deep groove, angular contact, and FOUR POINT CONTACT BEARING types) as well as hydrodynamic journal bearings used on crank and rod journals. Together, they translate combustion power into smooth, efficient, and reliable rotation.

For marine and industrial diesel engines, bearings are mission-critical. They carry persistent radial and axial loads, endure thermal cycles and vibration, and preserve the geometry that ensures fuel efficiency and long service intervals. When properly specified, installed, and maintained—especially with proven OEM parts—bearings safeguard the entire powertrain against wear, misalignment, and premature failure.

Technical Function of Bearings in High-Duty Engines

In an engine, bearings define the load path between rotating and stationary components. Journal bearings create a pressurized oil film that keeps metal surfaces apart, enabling the crankshaft to ride on a hydrodynamic wedge at operating speed. Rolling-element bearings use hardened raceways and rolling bodies to handle loads with minimal friction, ensuring reliable motion where oil-film formation is limited or where axial positioning and combined loads must be controlled.

The FOUR POINT CONTACT BEARING is a specialized angular contact ball bearing that manages axial loads in both directions with a single bearing while also accommodating radial loads. Its split inner or outer ring geometry creates four contact points between balls and raceways, enabling precise axial location of shafts and compact designs. In a marine engine gearbox, auxiliary drive, or turbocharger accessory, a FOUR POINT CONTACT BEARING maintains accurate axial clearance, helps absorb thrust from helical gears, and stabilizes the rotor or shaft during transient maneuvers. Specified as OEM parts, these bearings deliver predictable preload, optimized contact angles, and cage materials tuned for oil or grease lubrication in diesel engine environments.

- · High load capacity with compact dimensions

- · Accurate axial positioning and bidirectional thrust control

- · Low friction for better efficiency and temperature control

- · Stable operation under vibration and shock

- · Materials and heat treatments for long fatigue life

- · Clearance classes (e.g., C3/C4) matched to engine conditions

- · Compatibility with oil mist, splash, or forced lubrication

- · Dimensional stability over wide temperature ranges

FOUR POINT CONTACT BEARING Use Cases in Marine Engine and Diesel Engine Systems

In propulsion and auxiliary systems, FOUR POINT CONTACT BEARING solutions appear where combined loads and precise axial guidance are mandatory:

Reduction gears and cam drives: Helical gear thrust is managed without stacking paired angular contact bearings. Alternators and pumps: Compact housings benefit from axial control in limited space. Turbocharger accessories and gear trains: Stable axial location improves rotor dynamics and reduces vibration. Across these applications, correct preload and raceway geometry minimize skidding, reduce heat generation, and extend grease or oil life.

Importance for Engine Operation, Reliability, and Safety

Bearings have a direct impact on engine performance and uptime. Excessive clearance, misalignment, or contamination accelerates fatigue and pitting. Lubrication breakdown causes smearing and scuffing. Overloading leads to brinelling, spalling, and cage damage. The outcome is increased vibration, elevated bearing and oil temperatures, poor gear meshing, and potential shaft damage—issues that raise fuel consumption and can escalate to an unplanned shutdown.

By keeping shafts centered, controlling axial float, and maintaining proper geometry, well-specified bearings reduce frictional losses, stabilize oil films, and protect mating parts. In marine environments, corrosion-resistant materials, correct sealing, and clean-lubricant practices further extend service life and safeguard safety-critical operations in port approaches and offshore maneuvers.

Advantages of OEM Spare Parts Suitable for Bearings

Choosing OEM spare parts suitable for bearings ensures dimensional accuracy, consistent metallurgy, and validated load ratings across batches. Precision raceway finishing, controlled contact angles, and application-specific cage designs deliver predictable performance at operating speed and temperature. The result is measurable value in performance, reliability, budget, and service life:

- · Performance: Optimized clearances and preload minimize friction and heat, improving efficiency and power density.

- · Reliability: Proven materials, heat treatment, and surface finishes resist fatigue, fretting, and corrosion.

- · Budget: Longer service intervals, fewer unplanned stops, and reduced collateral damage lower total cost of ownership.

- · Service life: Tight tolerances and verified load ratings extend bearing and component lifespan under harsh duty cycles.

For a FOUR POINT CONTACT BEARING in a marine engine or diesel engine gearbox, OEM parts arrive with matched ring sets, certified clearances, and recommended preload/fit data. This ensures that shaft seating, thermal growth, and lubrication method (oil jet, bath, or mist) align with design intent.

FOUR POINT CONTACT BEARING OEM Parts: What to Expect

Engineered cages (machined brass or polymer), contact angles tuned for thrust-heavy duty, and precision raceway geometry allow stable axial guidance at high speed. Cleanliness standards, batch traceability, and acceptance testing reduce the risk of early-life failures. When combined with correct housing fits, shaft tolerances, and filtration, OEM parts help keep vibration within spec and protect gears, seals, and couplings.

MOPA: Fast, Secure Supply of OEM Bearings for Diesel and Gas Engines

MOPA is an experienced and reliable partner for OEM spare parts Bearings. We source and deliver FOUR POINT CONTACT BEARING solutions and complementary bearing types for diesel and gas engines with speed, quality, and security. Customers benefit from responsive lead times, technical matching of clearance and preload, and rigorous documentation for traceability.

Our team supports purchasers and technical decision-makers with application advice, from gearbox thrust bearings to auxiliary drive units. With robust logistics, careful packaging, and adherence to current standards, MOPA helps fleets and plants minimize downtime and keep equipment performing at specification.

Conclusion: FOUR POINT CONTACT BEARING and Bearings That Protect Your Powertrain

Bearings—especially the FOUR POINT CONTACT BEARING in combined-load locations—are central to the performance, efficiency, and safety of marine and diesel engines. Specifying OEM spare parts suitable for Bearings secures consistent quality, predictable fits, and long service life while protecting budgets through reduced downtime and maintenance effort.

Partner with MOPA to source the right OEM parts quickly and securely, and keep your engines operating reliably in every duty cycle.