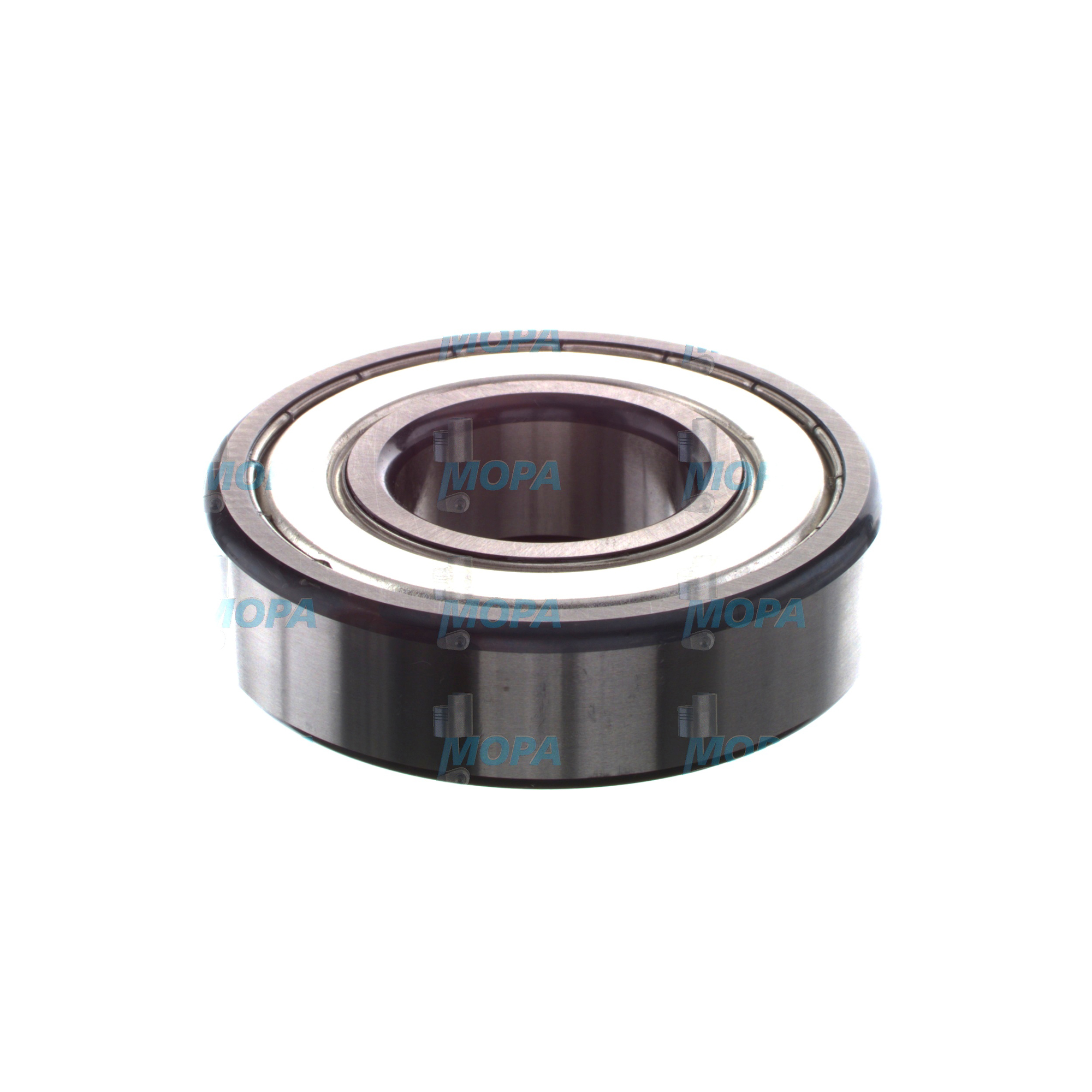

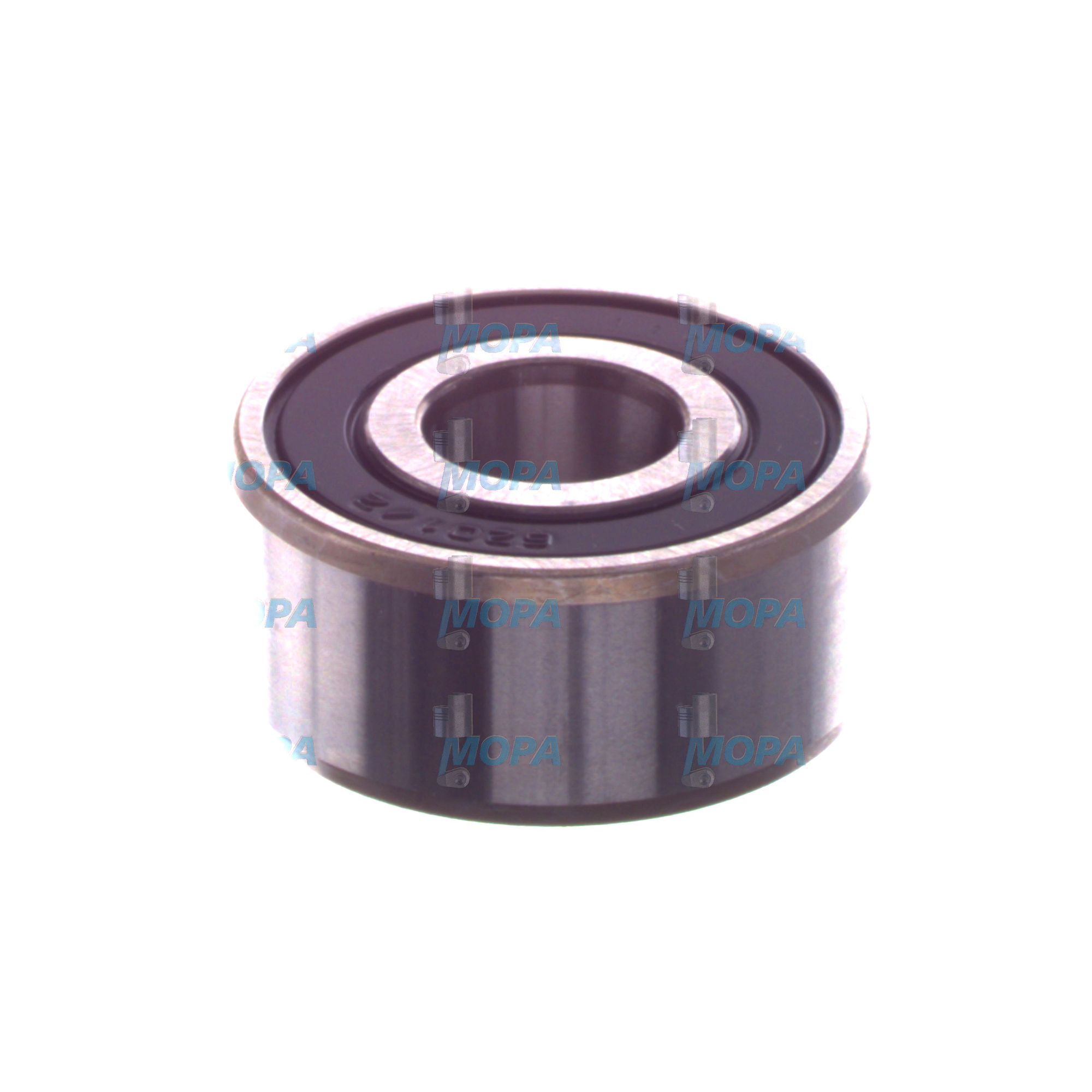

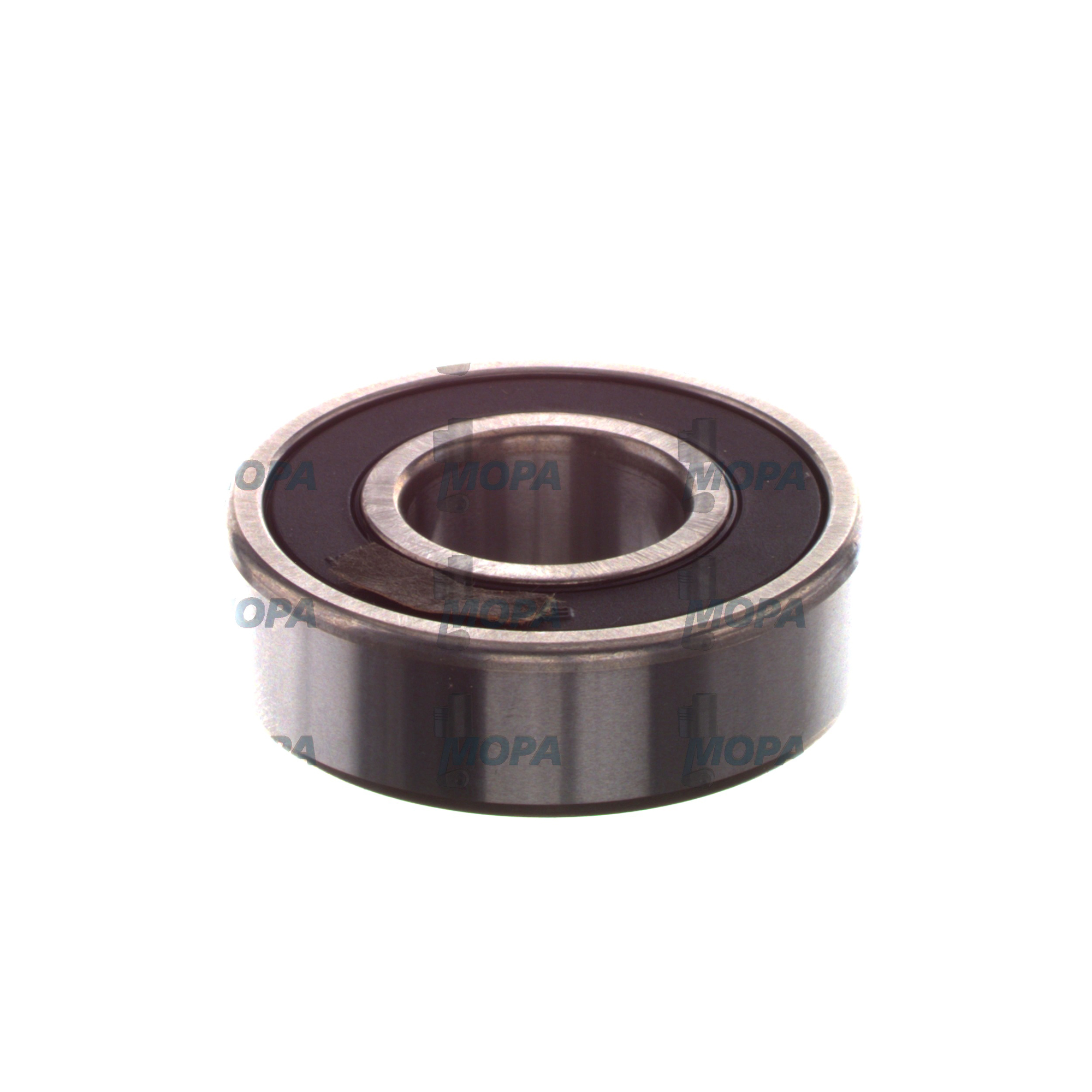

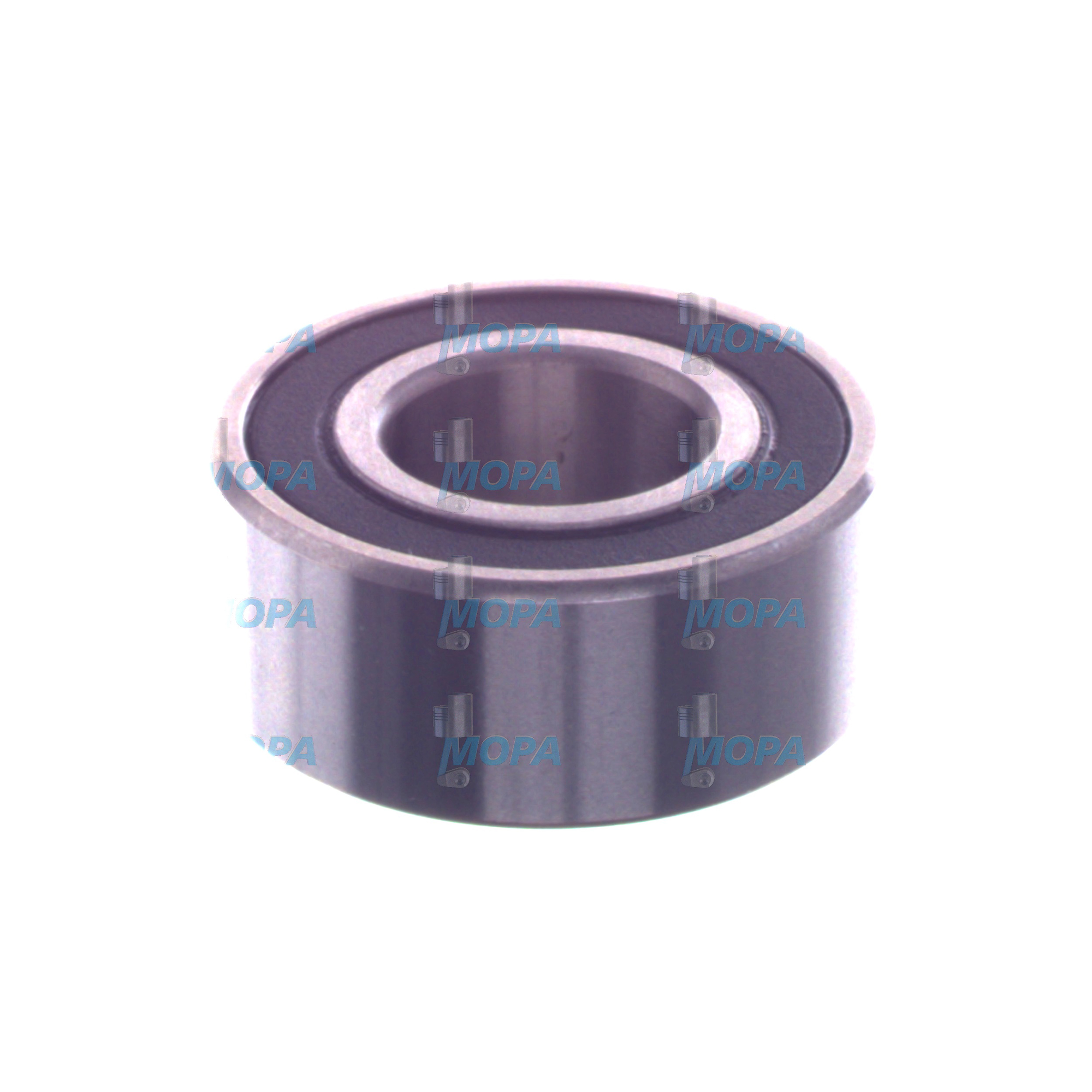

GROOVED BALL BEARING Bearings for Marine and Diesel Engines

Bearings are precision components that control friction and support rotating and oscillating parts inside engines. As a category, Bearings include deep groove ball bearings, plain bearings, roller bearings, and thrust designs—each tailored to carry specific loads, maintain alignment, and protect mating parts. In marine and diesel engines, they stabilize shafts, gears, and auxiliaries, ensuring smooth rotation, accurate timing, and efficient power transmission. Without the right bearing solution, engines consume more fuel, generate excess heat, and face premature wear of critical components.

Technical function of Bearings and the role of GROOVED BALL BEARING in a marine engine

Within an engine, Bearings separate moving surfaces with a precisely engineered rolling or sliding interface. They convert sliding friction into rolling friction, minimize energy losses, and control radial and axial loads. A GROOVED BALL BEARING is the most versatile of the rolling bearing family: its deep raceway geometry supports high radial loads and moderate axial loads from both directions, while its low-friction design enables high rotational speeds. In a marine engine or diesel engine installation, deep groove ball bearings are commonly found in alternators, coolant pumps, blower motors, belt tensioners, starter motors, and gearbox auxiliaries where reliable, quiet, and efficient operation is essential.

Key design elements include raceway curvature for optimal contact stress distribution, cage design (steel, brass, or polymer) for stability at speed, and seal or shield options to manage lubrication and contamination. GROOVED BALL BEARING OEM parts for propulsion or genset applications often specify C3/C4 internal clearances for thermal expansion, high-purity bearing steel for fatigue resistance, and surface finishes that reduce micro-pitting under cyclic loads. Correct fits (e.g., H7/g6) and preloads protect against vibration and fretting, maintaining concentricity in demanding engine environments.

· Low friction for reduced energy losses and cooler running.

· High-speed capability for alternators and auxiliary drives.

· Radial and axial load support in compact dimensions.

· Seal/shield options (2RS/ZZ) to control contamination and lubricant retention.

· Stable clearances (C3/C4) for high-temperature engine rooms.

· Robust cage materials suitable for continuous-duty operation.

· Precision tolerances for low vibration and noise.

· Corrosion-resistant variants for marine atmospheres.

Where a GROOVED BALL BEARING adds value in a diesel engine

In belt-driven systems, a GROOVED BALL BEARING delivers consistent tensioner performance and reduces belt slip, improving alternator efficiency and battery charging. In coolant and lube oil pumps, it manages combined radial/axial loads from impellers while maintaining sealing integrity. In electric starters and blower motors, it ensures fast spin-up with low noise and minimal current draw. These contributions translate into better fuel efficiency, fewer unplanned stops, and longer service intervals.

Importance for engine operation and service life

Bearings are central to engine reliability. If Bearings deteriorate—through lubrication failure, misalignment, contamination, overload, or incorrect clearance—friction increases, temperatures rise, and vibration escalates. Typical failure modes include spalling, brinelling, cage fracture, and fretting corrosion. Consequences range from accelerated wear of shafts and housings to seal leaks, belt failures, and, in severe cases, seizure of rotating elements that can cascade into expensive downtime.

Early indicators of bearing distress include elevated bearing metal temperatures, rising vibration at defect frequencies (BPFO/BPFI), abnormal noise, increased current draw in motors, or metallic debris in filters. Proactive replacement with correctly specified Bearings mitigates these risks and stabilizes engine performance over long operating cycles.

Advantages of OEM spare parts suitable for Bearings and GROOVED BALL BEARING

Choosing OEM spare parts suitable for Bearings ensures dimensional accuracy, consistent heat treatment, and proven material quality. This is critical for deep groove ball bearings in marine and diesel environments where thermal loads, shock, and contamination are frequent. Precision tolerances and verified clearances prevent micro-movements that cause fretting on shafts and housings. Engineered grease fills and seal designs keep lubrication where it matters, extending re-lubrication intervals and protecting against salt-laden air.

From a cost-of-ownership perspective, OEM spare parts suitable for GROOVED BALL BEARING applications reduce downtime by fitting correctly the first time, integrating with existing housings and seals, and maintaining designed performance across service intervals. Traceability and documented specifications support compliance and simplify audits, while consistent batch quality stabilizes vibration signatures—key for condition-based maintenance programs.

· Precise fits and clearances reduce vibration and heat.

· Verified metallurgy and heat treatment extend fatigue life.

· Correct seals and lubricants protect against ingress and washout.

· Consistent quality shortens installation time and minimizes rework.

· Lower lifecycle costs via longer intervals between overhauls.

· Reliable availability and documentation for fleet standardization.

MOPA as a partner for OEM parts: Bearings and GROOVED BALL BEARING

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality, and security in every transaction. For Bearings—including GROOVED BALL BEARING configurations—MOPA provides rapid quotations, short lead times, and controlled logistics to keep vessels and power plants on schedule. Customers benefit from technically correct cross-references, clear documentation, and dependable packaging that protects tolerances during transport.

Whether supporting a single auxiliary repair or a full overhaul kit, MOPA delivers application-matched bearing solutions for marine engine and power generation fleets, helping technical teams reduce risk and maintain predictable engine performance.

Conclusion

Bearings are essential to the efficiency, safety, and longevity of marine and diesel engines. A GROOVED BALL BEARING brings low friction, high speed capability, and dependable load support to critical auxiliaries and drive systems. With OEM spare parts suitable for Bearings, operators secure consistent performance, longer service life, and reliable upkeep of mission-critical equipment—backed by MOPA’s fast, secure, and quality-focused supply chain for diesel and gas engines.