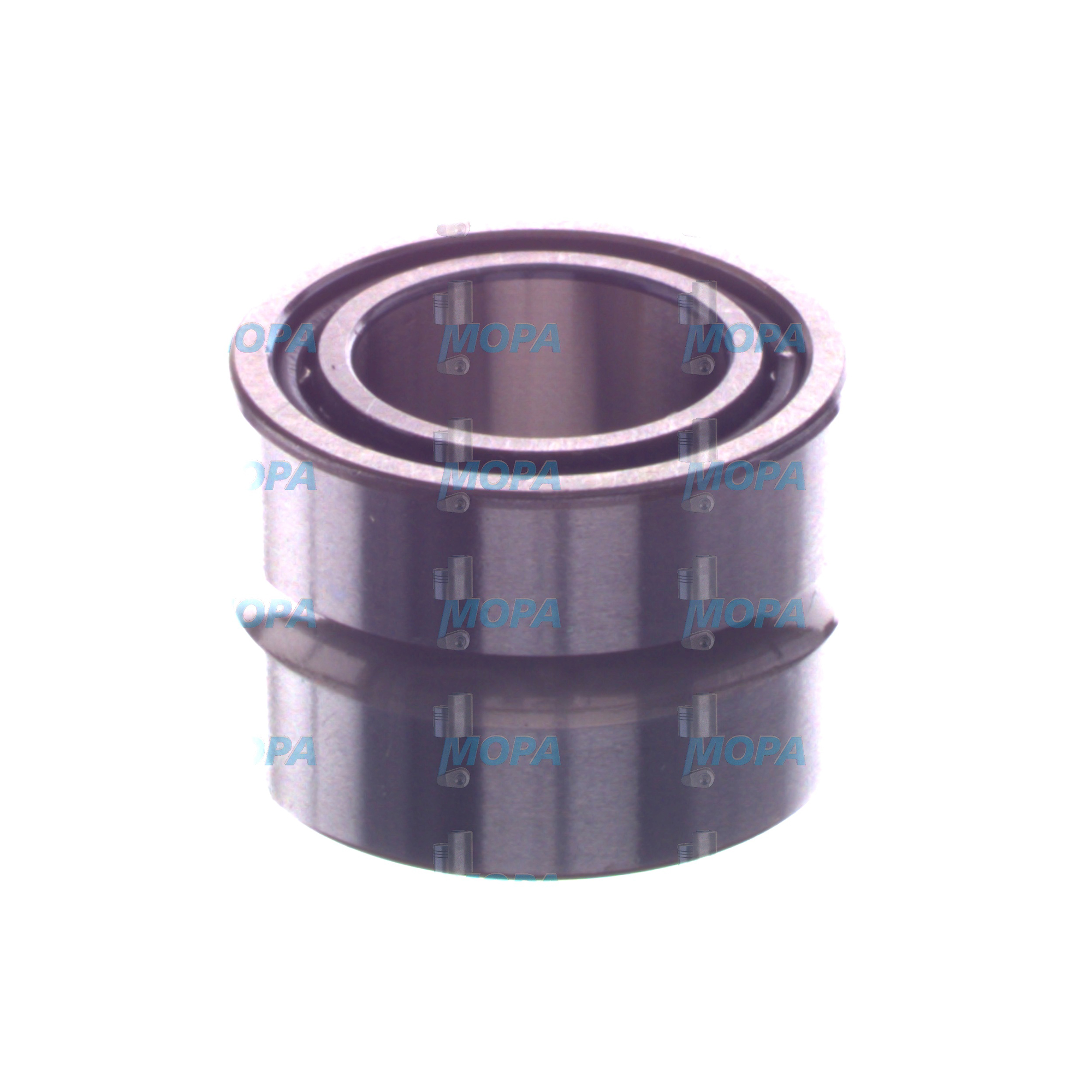

NEEDLE BEARING solutions in the Bearings category for marine and diesel engines

Bearings are precision-engineered components that support rotating and oscillating elements in engines while minimizing friction and wear. As a core category in heavy-duty propulsion and power generation, Bearings ensure that crankshafts, camshafts, gear trains, turbochargers, and auxiliary drives operate within defined clearances and alignment. From compact rolling elements to large-diameter journal types, the right design and quality of Bearings directly influence engine efficiency, reliability, and lifecycle cost.

Within this category, the NEEDLE BEARING stands out for its high radial load capacity in very tight installation spaces. By using slender cylindrical rollers, it provides robust support in connecting rod small ends, rocker arms, pumps, and gearbox shafts where envelope constraints are critical—common in marine engine and diesel engine layouts. Whether you are specifying components for a newbuild or planning maintenance on an in-service fleet, selecting the correct Bearings configuration and quality level is essential to safeguard uptime and performance.

Technical function of Bearings and NEEDLE BEARING in marine engine and diesel engine applications

Bearings have two principal jobs: carry loads and control motion. In engines, they manage both radial and axial loads while maintaining shaft alignment and limiting frictional losses. Rolling-element Bearings—ball, cylindrical roller, and NEEDLE BEARING types—use rolling contacts to reduce friction, enabling higher mechanical efficiency, lower heat generation, and tighter control of vibration. Plain (journal) Bearings create a hydrodynamic film that separates surfaces at operating speed, allowing very high load capacity with excellent damping characteristics.

The NEEDLE BEARING brings unique benefits. Its thin rollers significantly increase the contact area versus ball designs, enabling high radial load capacity in a compact package. This makes the NEEDLE BEARING ideal for diesel engine rocker shafts, idler gears, and auxiliary drives where space is limited but reliability is non-negotiable. In a marine engine, NEEDLE BEARING arrangements can be full-complement for maximum capacity or caged for better speed capability and lubrication control. Correct fits on shaft and housing, appropriate clearance class, surface hardness (typically >58 HRC for raceways), and oil film integrity are critical to achieving design life.

Lubrication strategy underpins performance. For rolling Bearings, elastohydrodynamic lubrication (EHL) minimizes metal-to-metal contact; viscosity selection, base oil type, and additive pack must match load, speed, and temperature profile. Sealing solutions (integrated seals or external labyrinths) keep contaminants out and lubricant in—vital for shipboard environments where salt, moisture, and particulates threaten bearing geometry. Thermal stability of materials, cage design (steel, brass, or engineered polymer), and precision ground raceways all contribute to low friction, reduced noise, and consistent service intervals.

- · High radial load capacity with compact dimensions (NEEDLE BEARING).

- · Optimized friction behavior for fuel-efficient operation.

- · Precise clearances for stable vibration and noise performance.

- · Robust materials and heat treatment for long service life.

- · Sealing and lubrication concepts tailored to marine environments.

- · Configurations for axial guidance, misalignment tolerance, and speed demands.

Importance for engine operation, reliability, and service life

Bearings are fundamental to engine durability. When they function correctly, load paths remain predictable, shaft alignment is preserved, and heat is controlled. A worn or improperly specified Bearing can trigger a cascade of failures: increased friction elevates oil temperature, clearances open or tighten unpredictably, and shaft runout grows. In severe cases, this leads to spalling, brinelling, cage fracture, and ultimately seizure—potentially damaging crankpins, cam lobes, gear teeth, or turbocharger cartridges. For shipowners, the result can include unscheduled dry-docking, lost charter time, and higher fuel burn due to rising mechanical losses.

Typical root causes of premature bearing distress include lubricant contamination (water, soot, salt), incorrect viscosity, misalignment, poor fits, and out-of-tolerance components. Condition-based maintenance—oil analysis, vibration trending, temperature monitoring, and endplay checks—helps detect early-stage issues. However, prevention begins with correct selection and consistent quality. Using the proper NEEDLE BEARING in a diesel engine rocker assembly or gear train maintains the engineered contact geometry and prevents edge loading, surface fatigue, and unexpected downtime.

Advantages of OEM spare parts suitable for Bearings and NEEDLE BEARING OEM parts

For mission-critical equipment, consistency and traceability matter. OEM spare parts suitable for Bearings deliver the dimensional precision, metallurgy, and surface finish that the engine design requires. This translates into quick, reliable installation and predictable performance across service intervals.

Key advantages of choosing OEM spare parts suitable for Bearings and NEEDLE BEARING OEM parts include:

- · Tight tolerances and verified clearances for correct fits and load distribution.

- · Material and heat-treatment specifications matched to engine loads and temperatures.

- · Proven cage designs and roller profiles for stable lubrication and longer life.

- · Compatibility with engine seals, lubricants, and adjacent components.

- · Batch traceability and documentation for compliance and maintenance records.

- · Lower total cost of ownership through reduced rework, fewer early failures, and optimized fuel efficiency.

For a NEEDLE BEARING marine engine application or a NEEDLE BEARING diesel engine gearbox, OEM parts maintain the intended geometry—crowned rollers, raceway finish, and internal clearance—to protect shafts and housings. The result is stable performance, minimized vibration, and confidence in planned maintenance schedules.

MOPA: your partner for OEM spare parts Bearings and NEEDLE BEARING OEM parts

MOPA is an experienced and reliable partner for OEM spare parts in the Bearings category. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines, supporting shipowners, operators, and service companies worldwide. From rapid identification of the correct NEEDLE BEARING variant to on-time delivery and documentation, MOPA streamlines procurement and minimizes downtime. Our team assists with technical cross-checks, material certifications, and logistics, ensuring the right part arrives ready for installation.

Conclusion

Bearings are fundamental to the efficiency and reliability of every marine engine and diesel engine, with the NEEDLE BEARING providing compact, high-capacity support where space is tight and performance is critical. Selecting OEM spare parts suitable for Bearings preserves engineered tolerances, improves predictability, and protects your budget over the entire lifecycle. Partner with MOPA to secure quality, speed, and security for all your Bearings and NEEDLE BEARING OEM parts needs.