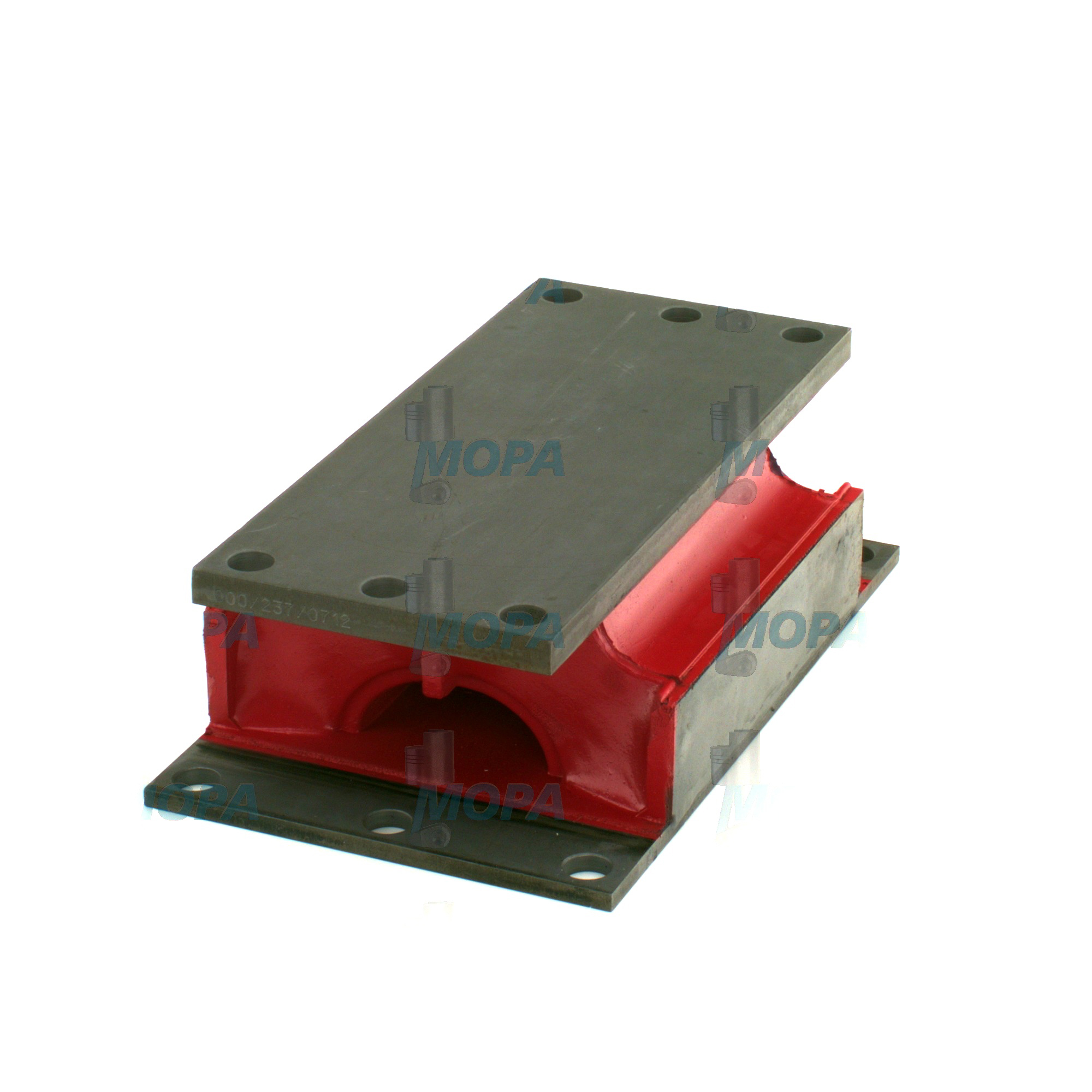

RUBBER MOUNT focus: Bearings for marine and diesel engines

Bearings are precision load-carrying components that support and guide rotating and reciprocating parts inside engines. In marine and diesel engines, they create controlled, low-friction interfaces between crankshafts, connecting rods, camshafts, balance shafts, and ancillary equipment. By maintaining accurate clearances and stable lubrication films, bearings convert metal-to-metal contact into smooth motion, enabling dependable starting, efficient operation, and long service intervals. Whether the installation uses a RUBBER MOUNT system on the foundation or not, bearings remain the hidden backbone of engine reliability.

The article category Bearings includes main bearings, big-end (connecting rod) bearings, thrust bearings for axial control, camshaft bearings, and specialized units such as turbocharger bearings. Across all types, material science, surface finish, and dimensional accuracy work together to manage high loads and continuous duty cycles typical of propulsion, auxiliary gensets, and industrial power.

Technical function of Bearings in a RUBBER MOUNT marine engine installation

In operation, engine bearings establish a hydrodynamic oil film that separates the journal from the bearing shell. As the shaft rotates, viscosity and speed create a pressure wedge that carries radial and (for thrust units) axial loads. This mechanism reduces friction, dampens vibration, and controls heat. The result is stable oil pressure, precise timing, and reduced wear on pistons, rings, and valve train. In a RUBBER MOUNT marine engine installation, vibration isolation at the base complements what bearings achieve inside the block: the mounts reduce transmitted structural vibration while the bearings control internal dynamic forces.

Main and connecting rod bearings are commonly tri‑metal (steel backing with copper/lead intermediate and soft overlay) or aluminum-based, selected for fatigue strength, embedability, and seizure resistance. Thrust bearings maintain crankshaft end-float for accurate gear or coupling alignment. Camshaft bearings ensure valve timing stability. Turbocharger bearings—either full-floating bushings or ball/roller cartridges—operate at very high speeds, where oil quality and clearances are critical to avoid coking and rotor imbalance.

Hydrodynamic film, clearances, and RUBBER MOUNT diesel engine dynamics

Correct bearing clearance is vital. Too tight, and the oil film collapses, generating heat and scuffing; too loose, and oil pressure drops, reducing load capacity and increasing noise. Surface finish, roundness, and alignment of housings and journals determine whether a robust oil wedge forms under all load states. In a RUBBER MOUNT diesel engine arrangement, reduced structural resonance can help maintain alignment under varying hull or skid deflections, indirectly supporting consistent bearing life. Lubricant viscosity, cleanliness, and temperature complete the system: the oil must reach the right gallery at the right pressure and flow, every cycle.

Key characteristics and advantages of Bearings

- · Low friction under high loads and continuous duty.

- · Hydrodynamic oil film protects journals from contact.

- · Precise clearances stabilize oil pressure and performance.

- · Material layers resist fatigue, corrosion, and seizure.

- · Axial control via thrust bearings protects couplings and gears.

- · Dimensional stability supports accurate timing and efficiency.

- · Compatible with condition monitoring and oil analysis strategies.

Why Bearings are critical for reliable engine operation

Bearings directly influence uptime and lifecycle cost. Degraded or mis-specified shells increase frictional losses, raise oil temperature, and erode performance margins. Contaminants can become embedded and score journals; misalignment and overload drive edge loading, fatigue cracking, and ultimately seizure. Symptoms include falling oil pressure, metallic debris in filters, unusual noise, and rising vibration. If not corrected, damage propagates to crankshafts, connecting rods, and housings—escalating repair scope and downtime.

For shipowners and power-plant operators, maintaining bearings in specification preserves fuel efficiency, keeps emissions control hardware operating within design windows, and ensures predictable maintenance intervals. Combined with proper RUBBER MOUNT diesel engine foundations and alignment practices, well-specified bearings help the entire powertrain run smoother and longer.

Advantages of OEM spare parts suitable for Bearings and RUBBER MOUNT OEM parts

Using OEM spare parts suitable for Bearings secures the dimensional fidelity and metallurgy that high-output engines require. Tolerances on shell thickness, crush, spread, and oil-hole geometry must match the housing and journal to form a stable oil wedge. The overlay composition, bonding integrity, and hardness gradient determine fatigue resistance and embedability. Traceable OEM production delivers this consistency across batches—critical in fleet standardization and long-term planning.

For performance, reliability, budget, and service life, the case is clear:

- · Fit accuracy preserves oil pressure and reduces friction losses.

- · Material specification sustains load capacity and fatigue life.

- · Consistent quality supports predictable maintenance windows.

- · Correct oil channeling minimizes temperature and varnish risk.

- · Fleet-wide standardization simplifies inventory and training.

Where installations also require vibration isolation, pairing high-grade bearings with RUBBER MOUNT OEM parts helps control both internal and transmitted vibration—supporting smoother couplings, cleaner sensor signals, and reduced noise levels, especially on passenger vessels and offshore units.

MOPA: fast, secure supply of OEM spare parts Bearings

MOPA is an experienced, reliable partner for OEM spare parts in the Bearings category. We combine technical expertise with rapid sourcing to keep diesel and gas engines in service. From main and con-rod bearings to thrust and camshaft sets, our team verifies specifications, aligns part codes, and arranges documentation and export handling with speed and precision. For projects that also require RUBBER MOUNT OEM parts, we coordinate matched deliveries so your maintenance window stays on schedule.

Customers value MOPA for quality-focused procurement, secure transactions, and responsive logistics—whether you operate blue-water vessels, coastal fleets, or power generation assets. Our network and product knowledge help reduce lead times and mitigate risk throughout the supply chain.

Conclusion

Bearings are fundamental to the performance and longevity of marine and diesel engines, ensuring low-friction support, stable oil pressure, and precise alignment. Selecting OEM spare parts suitable for Bearings—and complementing them with RUBBER MOUNT solutions where required—enhances reliability, protects budgets, and extends service life.