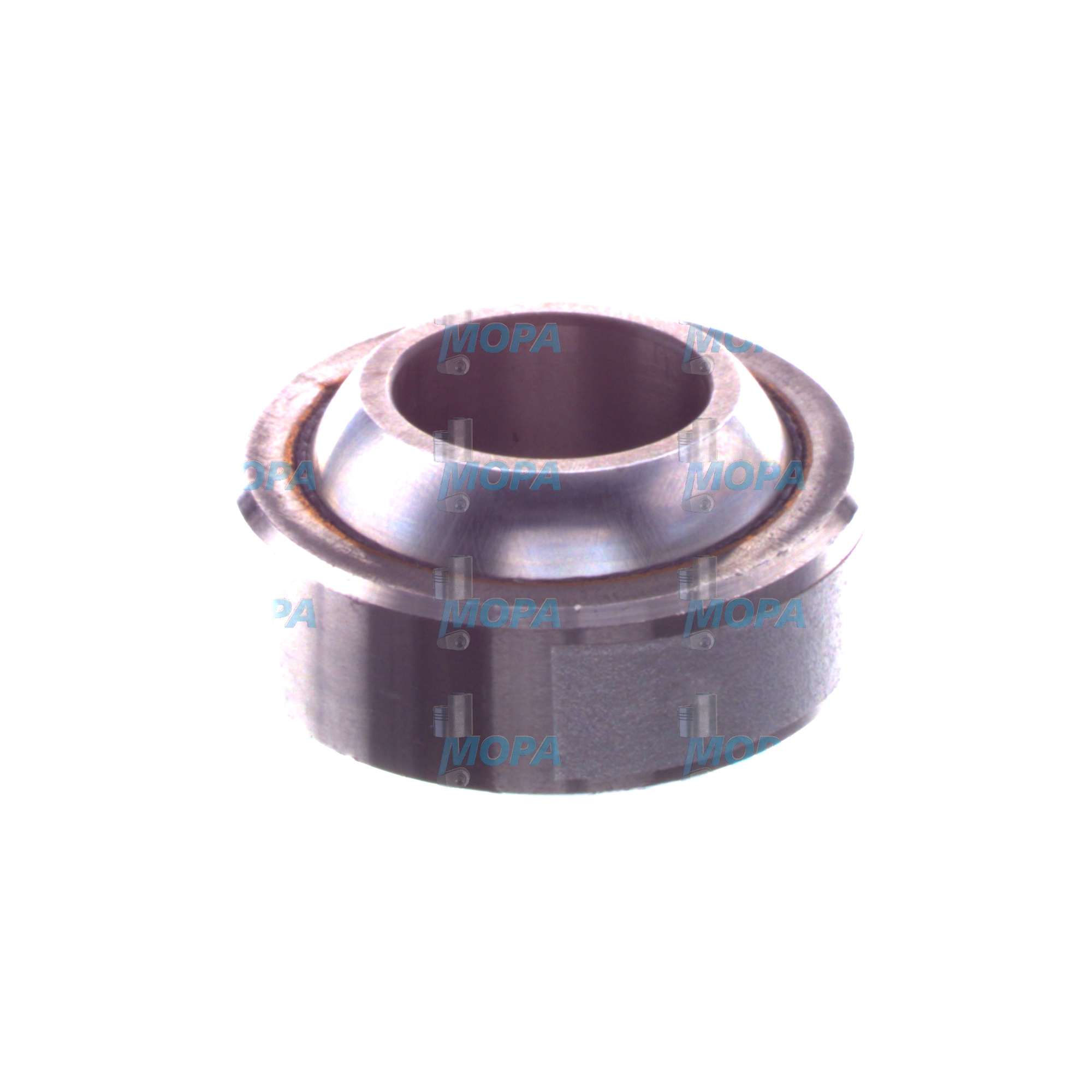

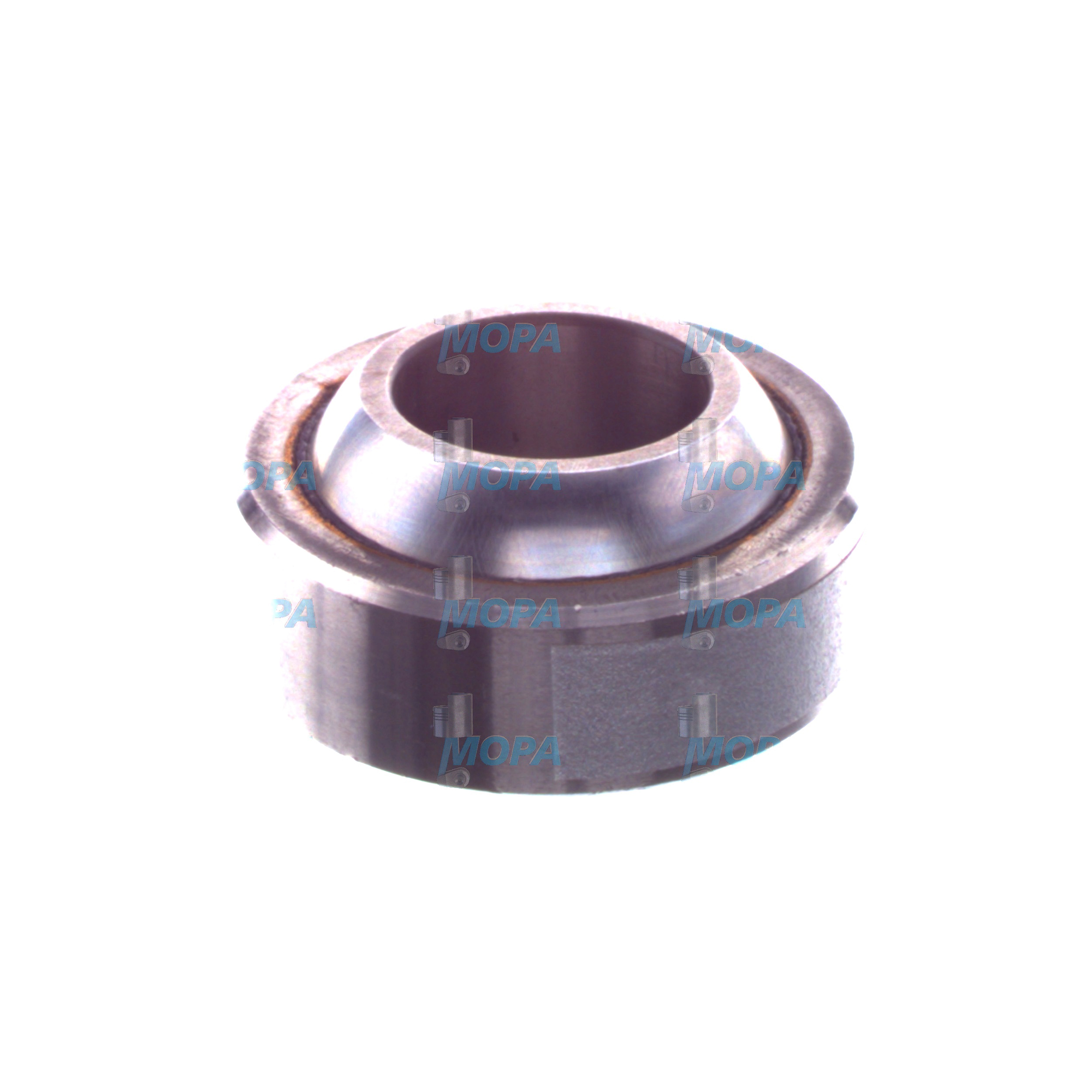

SPHERICAL PLAIN BEARING and high-performance Bearings for diesel and marine engines

Bearings are precision engine components that support rotating or oscillating shafts, rods, and housings while minimizing friction and wear. In large diesel and gas engines—especially in marine engine applications—bearings carry immense loads, maintain stable clearances, and enable reliable motion over thousands of hours. From crankshaft main and connecting-rod shells to camshaft, thrust, and auxiliary drive bearings, plus the SPHERICAL PLAIN BEARING used in control linkages and mounts, the category “Bearings” is fundamental to engine efficiency, power density, and safety.

Technical function: Bearings and the role of SPHERICAL PLAIN BEARING in engine assemblies

Within an engine, hydrodynamic plain bearings create an oil film that separates metal surfaces under load. Main and big-end bearings support the crankshaft, setting the foundation for smooth torque delivery and precise journal alignment. Camshaft bearings guide valve timing components. Thrust bearings control axial movement to protect gear trains and shaft seals. In parallel, the SPHERICAL PLAIN BEARING provides low-friction pivoting where misalignment occurs—typically in governor arms, fuel rack linkages, exhaust control mechanisms, and foundation mounts around a diesel engine or marine engine installation. By allowing oscillating movement and angular compensation, a SPHERICAL PLAIN BEARING reduces edge loading, protects pins and housings, and stabilizes motion under shock and vibration.

In practice, material systems and lubrication define performance. Tri-metal or aluminum-tin engine bearings rely on hydrodynamic films and precise geometry (crush, eccentricity, taper) to build oil pressure and prevent metal-to-metal contact. A SPHERICAL PLAIN BEARING may use steel-on-steel, PTFE-lined, or maintenance-free sliding couples to deliver consistent friction behavior in control rods—even where grease lines are impractical. In OEM parts configurations, this combination ensures consistent clearances, predictable thermal growth, and repeatable torque-to-turn values, supporting both performance and uptime.

SPHERICAL PLAIN BEARING applications in marine engine and diesel engine environments

On propulsion and genset systems, the SPHERICAL PLAIN BEARING appears in actuator joints, variable geometry linkages, remote-control rods, and resilient mounts where misalignment is unavoidable. In marine engine rooms, it also supports pump skids and accessory drives, absorbing vibration and cyclic loads. When specified as OEM parts, dimensional tolerance, corrosion protection, and liner materials are matched to diesel fuel environment, saline air, and high-frequency oscillation—preventing stick-slip, fretting, and galling that compromise control accuracy.

- · High load capacity for rotating and oscillating components

- · Stable oil film in main/big-end bearings under peak cylinder pressures

- · Misalignment compensation via SPHERICAL PLAIN BEARING joints

- · Material options: tri-metal, aluminum-tin, steel/PTFE for dry or lubricated duty

- · Corrosion-resistant solutions for marine engine environments

- · Precision geometry for cold start protection and hot running stability

- · Reduced vibration transmission and improved linkage accuracy

Importance for engine operation: reliability, efficiency, and safety

Bearings directly dictate engine reliability and service life. Excessive wear or incorrect clearance in main and rod bearings can lower oil pressure, cause mixed or boundary lubrication, and ultimately lead to scoring, seizure, or crankshaft damage. Cavitation, overlay fatigue, or debris embedding accelerates wear and contaminates the lubrication circuit, risking turbocharger and camshaft bearings downstream. In thrust bearings, loss of axial control can damage couplings, gears, or seals.

For a SPHERICAL PLAIN BEARING, degradation of the sliding couple—through corrosion, brinelling, or liner wear—introduces backlash and non-linear motion in fuel racks, governor linkages, and exhaust control. The result is unstable idle, uneven load sharing, increased emissions, and higher vibration transferred into nearby mounts and housings. Timely inspection and correct specification are essential to avoid unplanned downtime and costly overhauls.

Advantages of OEM spare parts suitable for Bearings

Selecting OEM spare parts for Bearings—plain shells, thrust elements, and every SPHERICAL PLAIN BEARING in a control chain—ensures the exact metallurgy, geometry, and surface finish intended by the engine design. That precision translates into consistent oil-film behavior, repeatable torque settings, and predictable service intervals. It also means mating fits, housing bores, and pin diameters align without rework, preserving maintenance schedules and minimizing idle time.

For performance, OEM spare parts protect efficiency by maintaining the designed hydrodynamic wedge and minimizing parasitic losses. For reliability, correct overlay thickness, bond integrity, and liner composition resist fatigue under high mean effective pressures. For budget, the right parts reduce collateral damage and short-interval rework, lowering lifecycle cost vs. repeated corrective maintenance. For service life, validated materials and clearances keep vibration, heat, and wear within specification across the full load profile of diesel and gas engines.

MOPA: fast, secure supply of OEM parts for Bearings and SPHERICAL PLAIN BEARING

MOPA is a proven partner for sourcing OEM spare parts in the Bearings category, including every SPHERICAL PLAIN BEARING required in marine engine and industrial diesel engine applications. We focus on speed—short lead times, efficient logistics, and responsive quotations—so critical engines return to service quickly. We emphasize quality—traceable sourcing, specification checks, and dimensional verification—to keep assemblies within design tolerances. And we deliver security in trade—reliable documentation and controlled supply chains—so purchasers and shipowners can buy with confidence for both diesel and gas engines.

Conclusion

Bearings—plain shells, thrust elements, and the SPHERICAL PLAIN BEARING—are core to engine performance, efficiency, and safety. Correct selection and timely replacement safeguard clearances, stabilize motion, and extend service life. With OEM spare parts suitable for Bearings and the support of MOPA, operators secure consistent performance, predictable maintenance, and dependable uptime across demanding marine and industrial engine fleets.