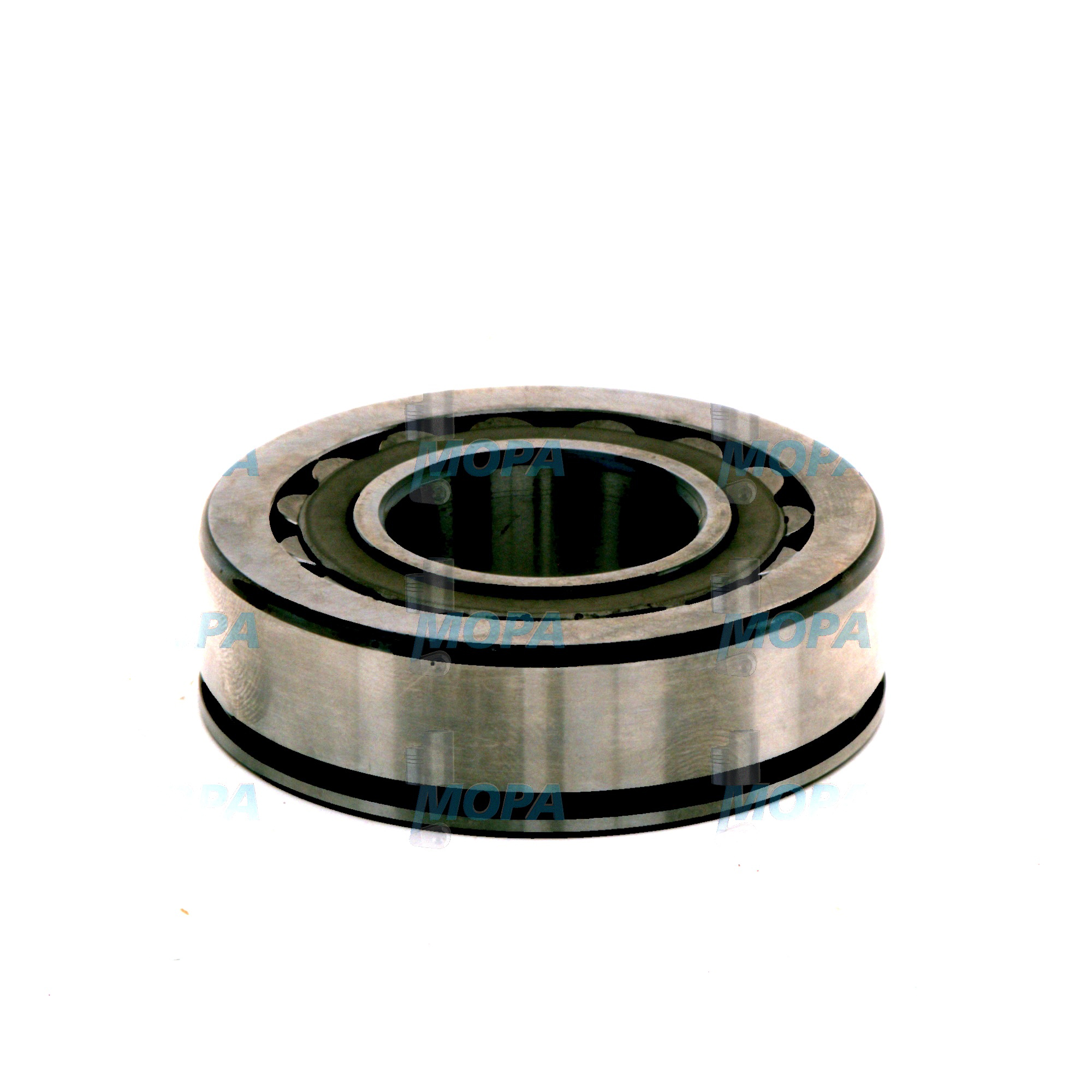

SPHERICAL ROLLER BEARING insights for engine-grade Bearings

Bearings are precision components that support and guide rotating parts in engines and powertrain equipment. They reduce friction, carry radial and axial loads, and keep shafts running on the intended centerline under high thermal and mechanical stress. In large diesel and gas engines—especially in marine engine rooms—bearings are found in crankshaft supports (plain bearings), camshaft carriers, gear trains, alternators, turbochargers, pumps, and auxiliary drives. Within this category, the SPHERICAL ROLLER BEARING stands out for its ability to carry very high radial loads and tolerate misalignment, making it indispensable in couplings, gearboxes, blower drives, and generator ends connected to the engine.

From compact gensets to two-stroke propulsion units, the right bearing selection directly influences uptime, vibration levels, and lifecycle costs. Engine builders and operators rely on robust, dimensionally stable bearings with precise clearances to achieve stable lubrication films, consistent performance, and predictable maintenance intervals. When load, speed, temperature, and contamination act simultaneously, bearings must deliver both mechanical strength and tribological efficiency—this is where engineered designs like the SPHERICAL ROLLER BEARING for diesel engine auxiliaries excel.

Technical function of Bearings in diesel and marine engine systems

Bearings in engines and engine-driven equipment carry the rotating mass while minimizing frictional losses. Rolling bearings such as the SPHERICAL ROLLER BEARING are selected where high radial loads, moderate axial loads, and misalignment (caused by baseframe deflection, thermal growth, or shaft bending) must be accommodated. Their self-aligning design—two rows of barrel-shaped rollers running in a common spherical raceway—keeps contact stress under control even when housings or shafts are not perfectly aligned, a common scenario in marine engine installations.

In gear trains and PTO arrangements on a diesel engine, these bearings stabilize shaft positions under shock and variable torque. In alternators and blower drives, a SPHERICAL ROLLER BEARING with C3/C4 internal clearance supports thermal expansion and prevents preload at temperature. Proper lubrication (oil bath, circulating oil, or high-performance grease) creates a film that separates surfaces and reduces wear. Cage materials—machined brass for high shock resistance or steel cages for high-speed duty—are chosen to match operating conditions. Clearance and tolerance classes (e.g., ISO P6/P5) ensure concentricity and low vibration, which protects gears, seals, and couplings downstream.

Load ratings (C, C0) and L10 life calculations per ISO 281 help size a bearing for the application. For marine engine auxiliaries subject to misalignment, high-capacity E-design SPHERICAL ROLLER BEARING options increase dynamic load rating, extending service life. Sealed variants add contamination control in salty or humid environments, while split plummer blocks simplify replacement on large shafts without disturbing the drivetrain.

Key characteristics and advantages of Bearings

· High load capacity with controlled friction.

· Tolerance for misalignment in harsh engine environments.

· Stable performance at elevated temperatures.

· Predictable L10 life with correct sizing and lubrication.

· Reduced vibration and noise for sensitive auxiliaries.

· Options for sealed, shielded, or open designs.

· Multiple cage materials for shock, speed, or temperature needs.

· Service-friendly housings and split units ease maintenance.

Why Bearings are critical for reliability and engine service life

When bearings degrade, the first symptoms are increased vibration, rising temperatures, and changes in power draw. Contamination, lubrication starvation, incorrect clearance, or persistent misalignment can trigger surface fatigue (spalling), smearing, brinelling, or cage wear. In diesel and marine engine contexts, these issues escalate quickly: gear mesh quality deteriorates, alternator output becomes unstable, and seals begin to leak. Unchecked, bearing damage can lead to shaft scoring, collateral damage to gears and couplings, and unplanned off-hire.

Maintaining proper fit tolerances, lubrication regime, and internal clearances is essential. Using the correct SPHERICAL ROLLER BEARING for a marine engine auxiliary or a high-torque diesel engine PTO helps maintain shaft geometry, reduces heat generation, and preserves the integrity of the lubrication film—extending intervals between overhauls and safeguarding major components.

Advantages of OEM spare parts suitable for Bearings

Engineered interchangeability and material consistency are decisive for uptime. OEM spare parts suitable for Bearings ensure that dimension tolerances, heat treatment, steel cleanliness, and cage design match the engine builder’s specification, so the bearing behaves as intended under load, speed, and temperature.

· Precise fit and clearance for faster installation and correct preload.

· Verified metallurgy and heat treatment for fatigue resistance.

· Consistent geometry for low vibration and reduced energy loss.

· Tested lubrication compatibility for extended relubrication intervals.

· Traceability and documentation that support compliance and audits.

· Lower total cost of ownership through longer service life.

· Reduced risk of early failures and unplanned downtime.

· Availability of matched sets and housing solutions for complex drives.

For mission-critical equipment like a SPHERICAL ROLLER BEARING in a marine engine gearbox or a diesel engine alternator, choosing OEM parts protects performance, improves reliability, and supports budgeting by lowering lifecycle costs.

MOPA — your partner for OEM parts Bearings and SPHERICAL ROLLER BEARING supply

MOPA supplies OEM spare parts suitable for Bearings across diesel and gas engine platforms with speed, quality, and security in every transaction. Our sourcing network and technical know-how help purchasers and shipowners specify the correct SPHERICAL ROLLER BEARING for marine engine auxiliaries, gear trains, or generator ends, including sealed and high-capacity variants, appropriate clearance classes, and compatible housings.

We prioritize fast response, meticulous documentation, and reliable logistics to minimize downtime. From single replacements to planned overhauls, MOPA provides OEM parts that align with engine builder standards, enabling predictable maintenance and stable performance across your fleet or plant.

Conclusion

Bearings are foundational to engine performance, efficiency, and safety, with the SPHERICAL ROLLER BEARING playing a key role wherever high loads and misalignment occur. Selecting OEM spare parts suitable for Bearings secures fit, materials, and performance—supporting longer service life and lower operating costs. Partner with MOPA to access the right OEM parts quickly and confidently for diesel and gas engine applications.