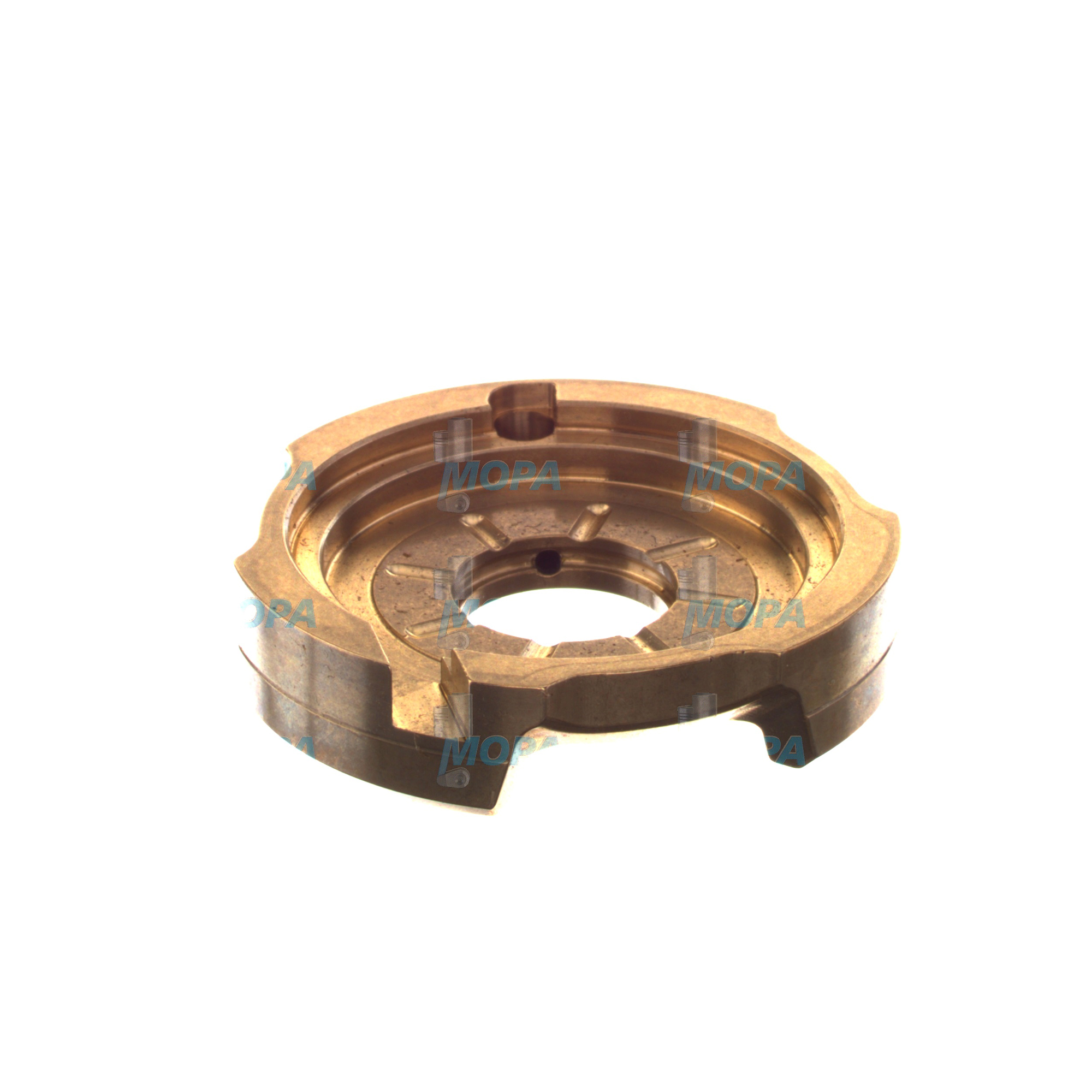

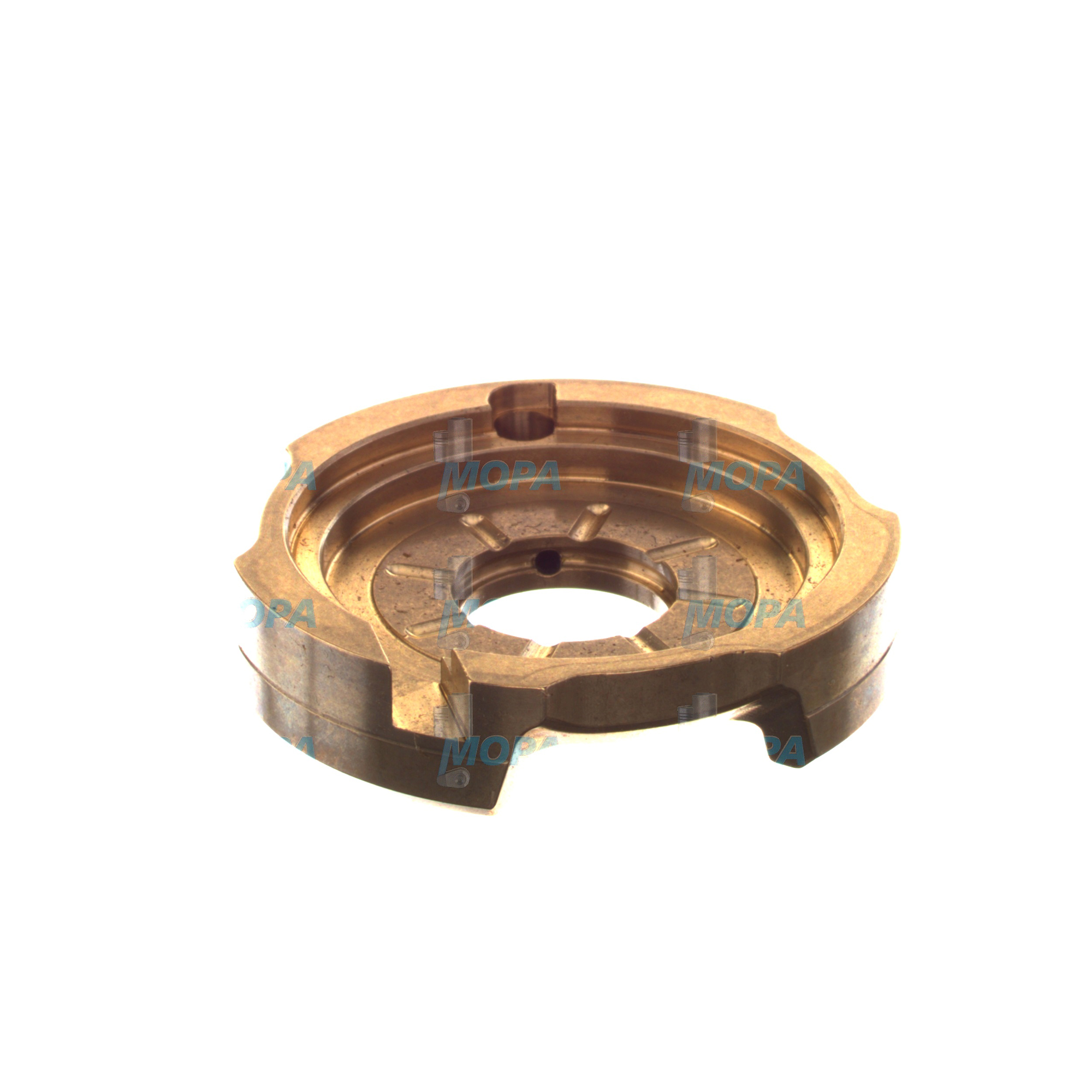

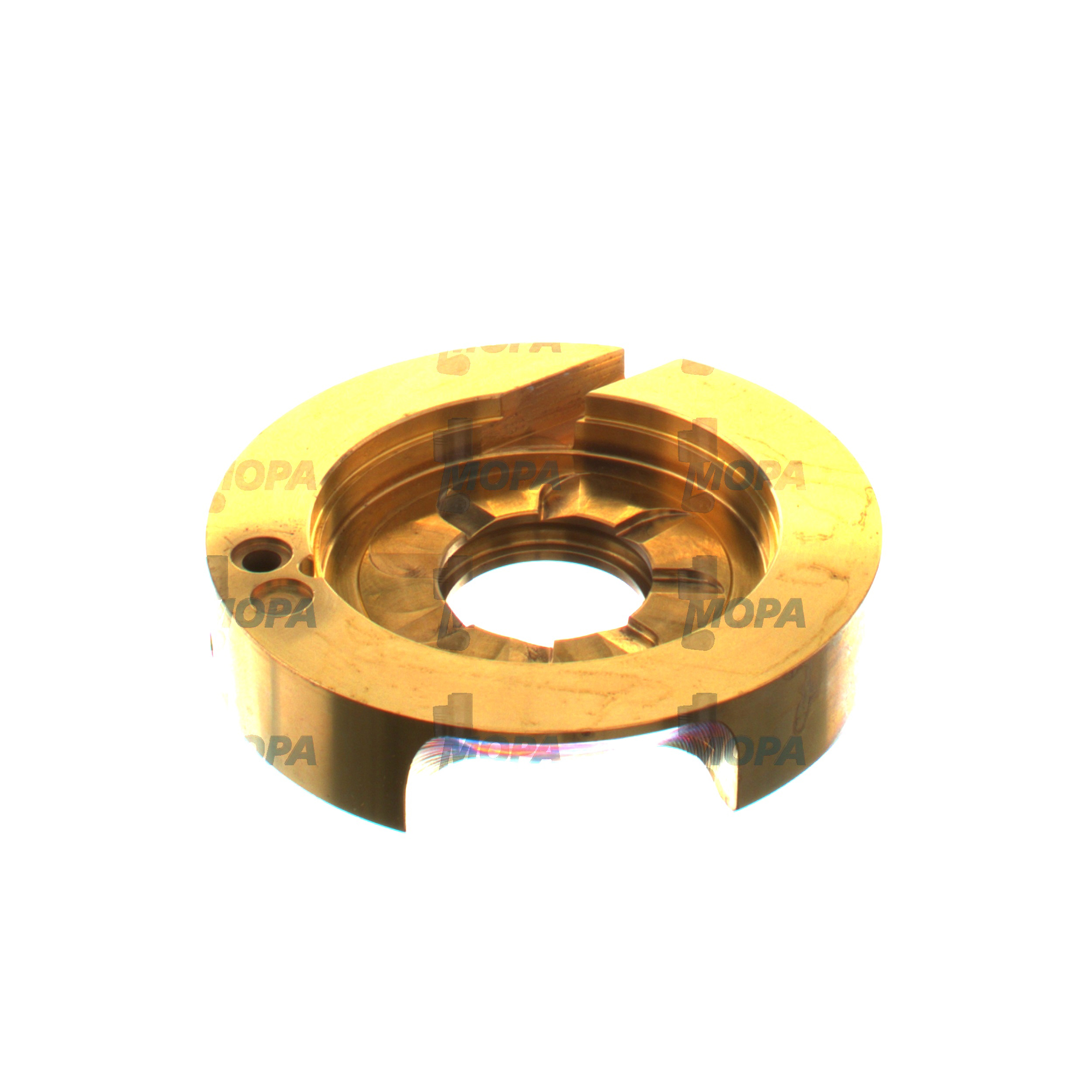

THRUST BEARING – Bearings for Marine and Diesel Engines

Bearings are precision-engineered components that support rotating assemblies, reduce friction, and carry radial and axial loads inside an engine. Within this broad category, the THRUST BEARING is the element responsible for controlling axial forces on the crankshaft, while main and connecting-rod bearings manage radial loads. Together, these bearings preserve alignment, minimize wear, and convert fuel energy into reliable mechanical output with minimal losses—making them indispensable to every marine engine and diesel engine.

In heavy-duty applications, the THRUST BEARING takes on the critical job of absorbing axial loads generated by the powertrain. In a marine engine, it counters propeller thrust transmitted through the shaft line; in a diesel engine driving helical gears, it resists the axial component created by gear tooth geometry. Without a correctly specified and maintained thrust assembly, the crankshaft would drift axially, damaging seals, gears, and couplings and undermining engine efficiency and safety.

Because the article category is Bearings, it is useful to view the THRUST BEARING as part of an engineered system. Main bearings, big-end bearings, crosshead bearings, camshaft bearings, and the thrust set work in concert to hold precise clearances, support the oil film, and keep the engine stable across the full load range. Selecting the right bearing design and material pairing is therefore central to performance, service life, and cost control.

THRUST BEARING function in a diesel engine and marine engine

A THRUST BEARING controls crankshaft end float and carries axial load via a hydrodynamic oil film. The typical configuration uses either thrust faces integrated into main bearing shells or a dedicated tilting-pad THRUST BEARING with multiple pivoting shoes surrounding a collar on the crankshaft. When the shaft rotates, oil is drawn into converging wedges between the thrust faces and the collar, creating a pressure field that supports axial load without metal-to-metal contact.

In a marine engine, the thrust set is positioned to accept propeller thrust under ahead and astern operation. Proper oil supply, pad geometry, and pivot design stabilize the hydrodynamic film across the entire operating envelope, including low-speed maneuvering and high-load steaming. In a diesel engine coupled to gearboxes or alternators, stable axial control prevents gear misalignment, end-float excursions, and thermal growth from pushing the crankshaft into damaging contact with stationary surfaces.

Lubrication, materials, and design of THRUST BEARING OEM parts

THRUST BEARING OEM parts typically combine a steel backing with a bronze or copper-based intermediate layer and a white-metal (Babbitt) overlay optimized for conformability and embedability. Tilting-pad designs use precision pivots to equalize load across pads, improving film stability and reducing edge loading. Features such as directed lubrication grooves, pocketed pad surfaces, and temperature-sensor provisions enhance safety and monitoring. Correct surface finish, pad flatness, and collar run-out are essential to preserve the oil film and prevent localized heating, scoring, or wipe.

- · High axial load capacity with stable hydrodynamic film.

- · Precise end-float control to protect gears, seals, and couplings.

- · Low friction for improved fuel efficiency.

- · Robust metallurgy for fatigue and cavitation resistance.

- · Optimized pad geometry and pivot design for load sharing.

- · Reliable lubrication paths and temperature monitoring options.

- · Dimensional accuracy and surface finish aligned with OEM parts.

- · Proven performance in marine engine and stationary diesel engine duty.

Why Bearings and THRUST BEARING are critical for engine reliability

Bearings define the running clearances that preserve oil pressure, control vibration, and maintain gear and coupling alignment. When a THRUST BEARING or other bearing wears beyond limits, the immediate risks include rising end float, contact between the crankshaft thrust collar and stationary faces, heat generation, and rapid overlay loss. Secondary effects can be severe: gear backlash deviation, accelerated seal wear, oil contamination with metal particles, fluctuating oil pressure, and rising bearing shell temperatures. In marine propulsion, excessive axial movement can disturb shaft-line alignment and increase fuel burn; in power generation, it can lead to tripping, unplanned stops, and costly downtime.

Routine measurements—such as end-float checks, collar run-out, and oil condition monitoring—help detect early stages of distress. Correct bearing selection, adequate oil film thickness, and proper installation practices are pivotal to extend service intervals, sustain efficiency, and protect major components like the crankshaft and gear train.

Advantages of OEM spare parts suitable for Bearings and THRUST BEARING

Choosing OEM spare parts suitable for Bearings ensures that geometry, clearances, and metallurgical systems match the engine builder’s intent. This alignment translates into predictable oil-film behavior, lower friction losses, and consistent temperature profiles under both transient and continuous operation. The result is dependable performance and longer service life for the crank train.

Beyond performance metrics, OEM spare parts provide dimensional consistency that speeds installation, reduces the need for corrective machining, and improves first-time fit. Traceable production, material certificates, and controlled surface finishes help technical teams meet audit and classification requirements. Over time, the right bearings stabilize maintenance budgets by minimizing premature replacements, limiting collateral damage, and keeping lube-oil systems clean.

How OEM parts for THRUST BEARING protect performance and budget

With bearings, small deviations produce large consequences. OEM parts for a THRUST BEARING deliver correct pad curvature, pivot geometry, and overlay thickness so the hydrodynamic film forms as intended across the whole operating range. This precision reduces heat generation, mitigates wipe risk, and preserves axial control. The net effect is higher availability, fewer emergent work orders, and a better total cost of ownership across marine engine and diesel engine fleets.

MOPA – OEM partner for Bearings and THRUST BEARING

MOPA is an experienced and reliable partner for OEM spare parts Bearings, including every variant of THRUST BEARING used in diesel and gas engines. Customers value rapid quotations, short lead times, and consistent quality in the trade of OEM parts. Whether supporting a transoceanic vessel or a power plant, MOPA combines vetted supply chains with careful documentation and secure logistics to keep critical assets online.

From single bearing shells to complete tilting-pad thrust sets, MOPA provides technically correct selections, clear traceability, and support for installation planning. The result is a streamlined procurement process that reduces risk and safeguards engine performance across marine and industrial applications.

Conclusion

Bearings—especially the THRUST BEARING—are central to engine efficiency, safety, and longevity by controlling axial and radial loads with precision. Selecting OEM spare parts suitable for Bearings preserves the intended oil film dynamics, stabilizes operating costs, and protects vital components over the long term.

With MOPA as a partner for OEM parts, purchasers, shipowners, and technical teams can secure speed, quality, and confidence in every bearing procurement decision.