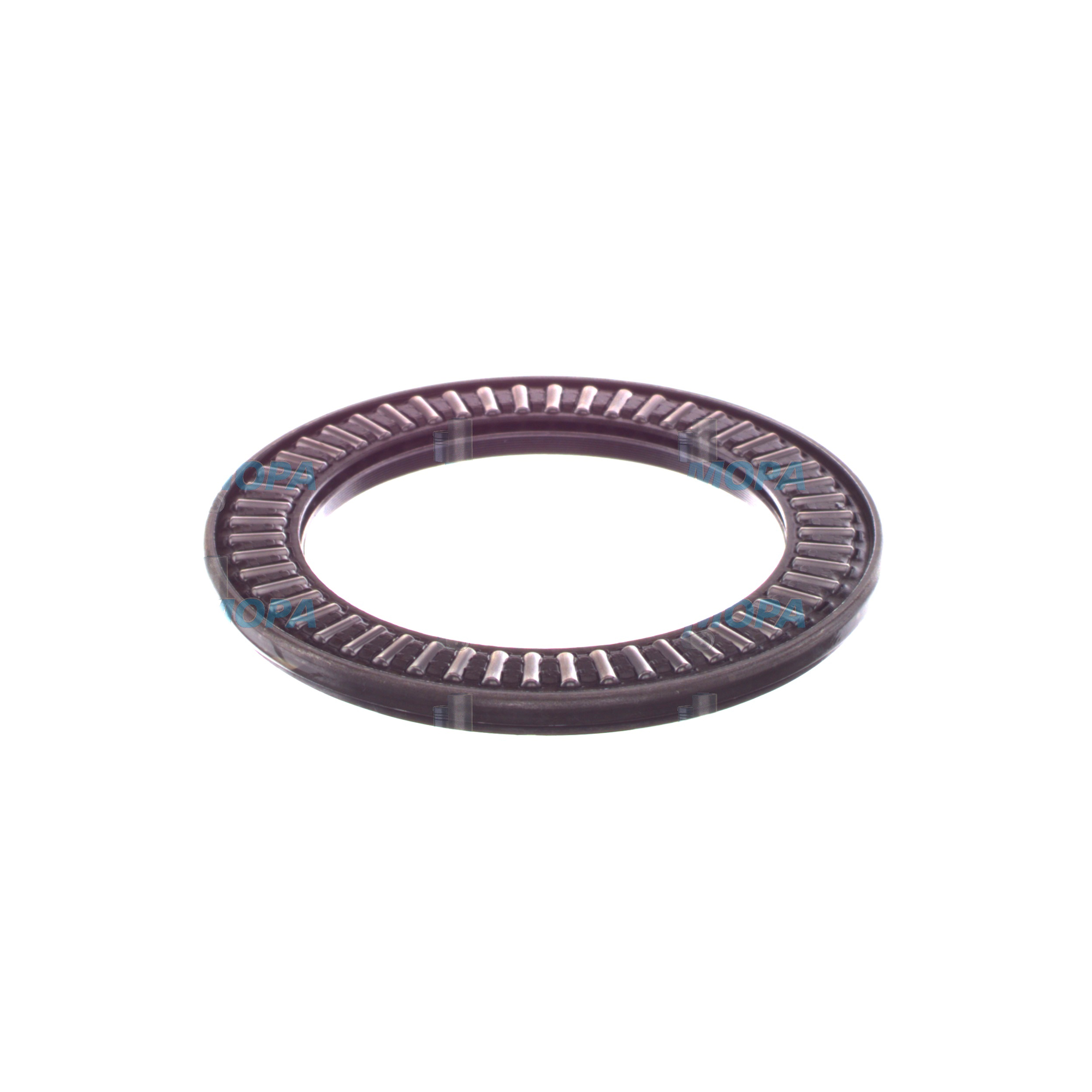

THRUST NEEDLE BEARING Bearings for marine, diesel and gas engines

Bearings are precision engine components that minimize friction, guide shafts, and carry both radial and axial loads. Within combustion engines—marine engine, diesel engine, and gas engine alike—bearings support the crankshaft, camshaft, gear trains, and auxiliary drives while keeping moving parts aligned under thermal expansion and dynamic load. From journal shells to rolling-element designs, bearings are fundamental to reliable power transmission, stable oil pressure, and consistent efficiency.

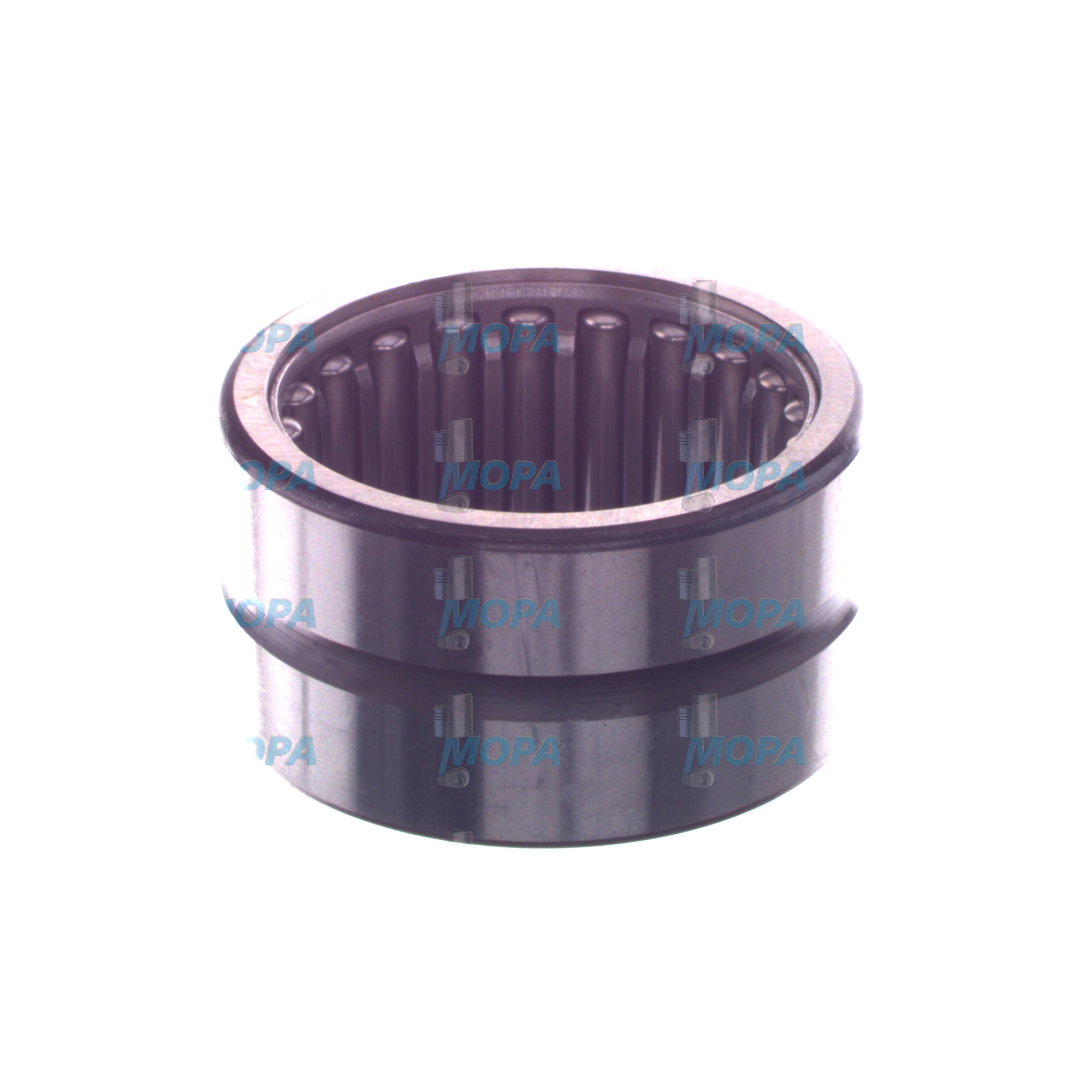

As an article category, Bearings covers a family of solutions: plain (hydrodynamic) bearings for high-speed journal support, cylindrical and needle bearings for compact radial load capacity, and axial solutions such as the THRUST NEEDLE BEARING where axial forces must be carried with minimal friction and heat generation. Selecting the correct type and specification is critical to engine uptime, component life, and operating cost.

Technical function of Bearings and THRUST NEEDLE BEARING in a diesel engine

In engines, bearings separate surfaces with an oil film or rolling contact to prevent metal-to-metal contact. Plain main and conrod bearings build a hydrodynamic wedge that centers the shaft. Rolling-element bearings, such as a THRUST NEEDLE BEARING in a diesel engine or marine engine gearbox, use needle rollers between hardened washers to carry high axial loads in a compact envelope. This keeps axial play within specification, stabilizes gear mesh under thrust from helical gears, and protects the crankshaft or intermediate shafts from end-float induced wear.

A THRUST NEEDLE BEARING marine engine application commonly appears in reduction gear assemblies, camshaft drives, and accessory drive stacks where space is limited but axial load is significant. The bearing’s washers serve as raceways, while needle rollers—often cage-guided for uniform spacing—provide low-friction rolling contact. Proper oil supply and surface finish (raceway hardness, roundness, and Ra) ensure elastohydrodynamic lubrication under boundary-prone start/stop conditions. When sourced as THRUST NEEDLE BEARING OEM parts, tolerances, heat treatment, and surface geometry align with the engine maker’s design intent, preserving axial alignment and minimizing parasitic losses.

Beyond axial control, Bearings ensure efficiency by reducing frictional power loss, heat generation, and wear particles that would otherwise contaminate the lubrication circuit. Correct bearing clearance maintains oil pressure stability, improves vibration behavior, and sustains fuel efficiency by preserving ideal timing and gear mesh conditions.

- · High load capacity with compact dimensions.

- · Stable axial guidance and controlled end-float.

- · Precision tolerances for consistent clearances.

- · Low friction for reduced heat and energy loss.

- · Surface hardness and finishes suited to EHL conditions.

- · Reliable operation in marine engine and diesel engine duty cycles.

- · Designed for clean oil flow and robust lubrication.

Importance for engine operation and service life

Bearings directly determine engine reliability. If clearances drift or axial control is lost, shaft alignment degrades, oil film collapses locally, and temperatures rise. In practice, worn Bearings can cause low oil pressure, gear noise, unstable timing, shaft fretting, and accelerated wear of mating components. For marine engine drive trains, insufficient axial support can transmit excess thrust into housings or the crankshaft, risking fatigue cracks or spalling of raceways.

Common failure modes—contamination abrasion, false brinelling from vibration, lubrication starvation, misalignment, and electrical erosion—reduce bearing life and can escalate into costly unplanned downtime. A failed THRUST NEEDLE BEARING can allow excessive end-float, leading to helical gear edge loading, increased backlash, and heat spots that propagate into neighboring parts. Maintaining Bearings in specification preserves oil cleanliness, reduces NVH, and safeguards service intervals.

Advantages of OEM spare parts suitable for Bearings

Using OEM spare parts suitable for Bearings delivers measurable gains in performance, reliability, budget control, and service life. Engineered to the engine builder’s drawings, OEM components replicate the intended metallurgy, heat treatment, surface finish, and dimensional tolerances. That precision translates to correct fits, predictable clearances, and stable lubrication behavior right from installation—shortening commissioning times and reducing rework risk.

OEM spare parts safeguard total cost of ownership by extending maintenance intervals and reducing secondary damage. Consistent geometry across batches simplifies inventory planning and speeds overhaul while maintaining compliance with technical documentation. For critical stations—propulsion, auxiliary gensets, and compressors—the repeatability of OEM Bearings sustains efficiency targets and protects uptime.

THRUST NEEDLE BEARING OEM parts for marine engine and diesel engine applications

THRUST NEEDLE BEARING OEM parts ensure that washer hardness, roller grade, cage material, and micro-geometry match the load spectrum of the specific marine engine or diesel engine. Correct axial height and parallelism maintain precise end-float, while optimized surface topography supports EHL film formation under transient loads. The result is lower friction, lower operating temperature, and extended bearing and gear life with minimal axial drift over time.

MOPA as your partner for OEM spare parts Bearings

MOPA is an experienced and reliable partner for OEM spare parts Bearings. We move quickly—from enquiry to dispatch—to minimize downtime on diesel and gas engines in marine and land-based power applications. Our focus on quality means traceable sourcing, specification-driven selection, and meticulous handling to protect precision surfaces. Transaction security is central to our process: clear documentation, export compliance, and dependable logistics give purchasers and technical teams confidence at every step.

Whether you need a THRUST NEEDLE BEARING for a gearbox overhaul or journal Bearings for a major service, MOPA delivers the right OEM parts on schedule, with technical support that aligns components to the engine’s operating profile and maintenance strategy.

Conclusion: Bearings and THRUST NEEDLE BEARING in focus

Bearings—especially the THRUST NEEDLE BEARING—are pivotal to axial control, efficiency, and long service life in marine engine and diesel engine systems. Accurate fit, correct materials, and proper lubrication behavior determine overall engine reliability.

Choosing OEM spare parts suitable for Bearings preserves performance, reduces lifecycle costs, and protects critical assets. With MOPA as your partner, you secure speed, quality, and security in the sourcing of OEM parts for diesel and gas engines.