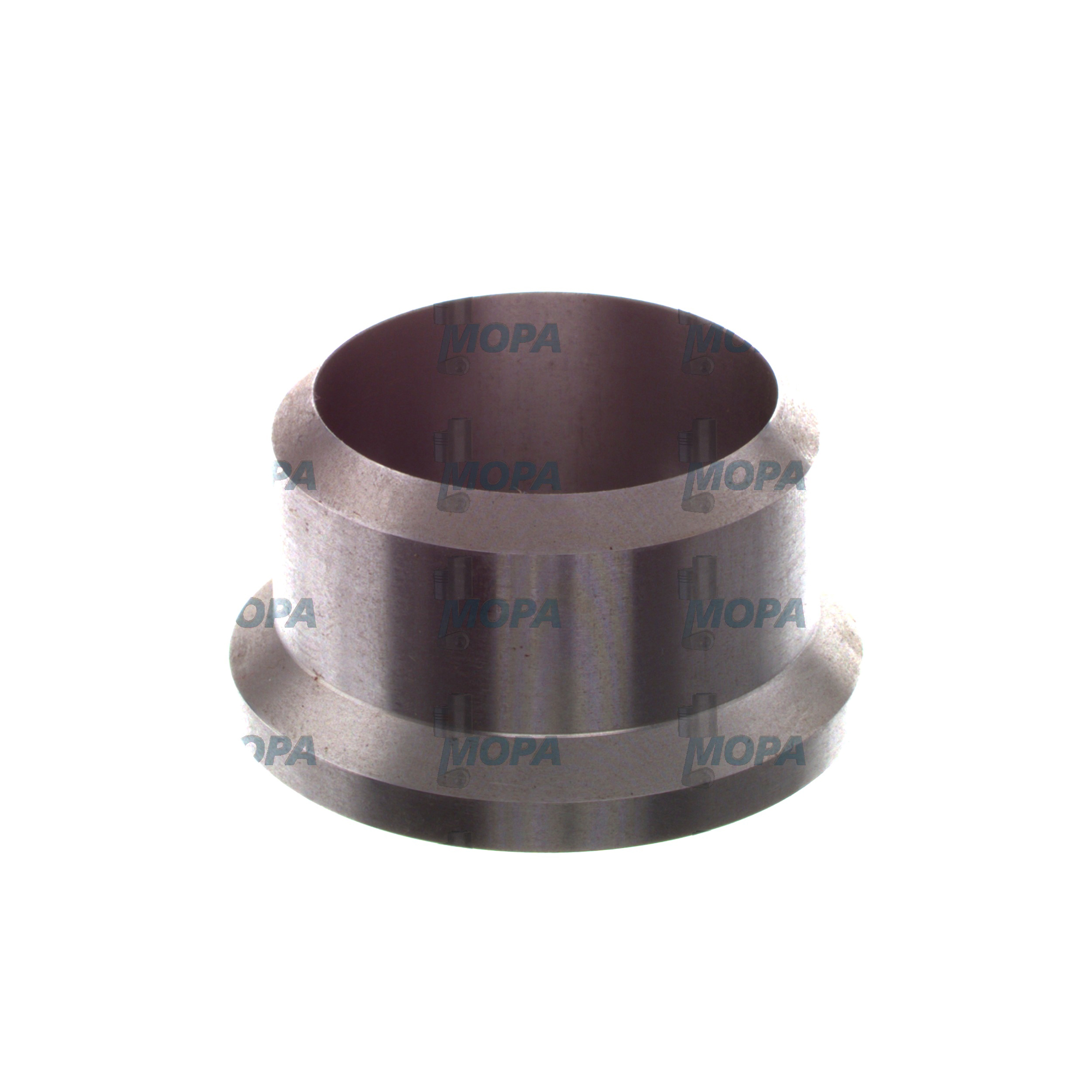

THRUST RING Bearings for marine and diesel engines

Bearings are precision components that support rotating and oscillating parts inside engines. In large marine and industrial diesel and gas engines, they minimize friction between the crankshaft, connecting rods, and camshaft journals, stabilize the rotating assembly, and maintain exact shaft alignment under high thermal and mechanical loads. Within this category, thrust bearings and their THRUST RING elements control axial movement, protecting the crankshaft and gearbox from end-thrust forces. Because bearings define clearances, oil film stability, and load distribution, they are a decisive factor for performance, efficiency, and service life across the entire powertrain.

Technical function of Bearings and the THRUST RING in a marine engine

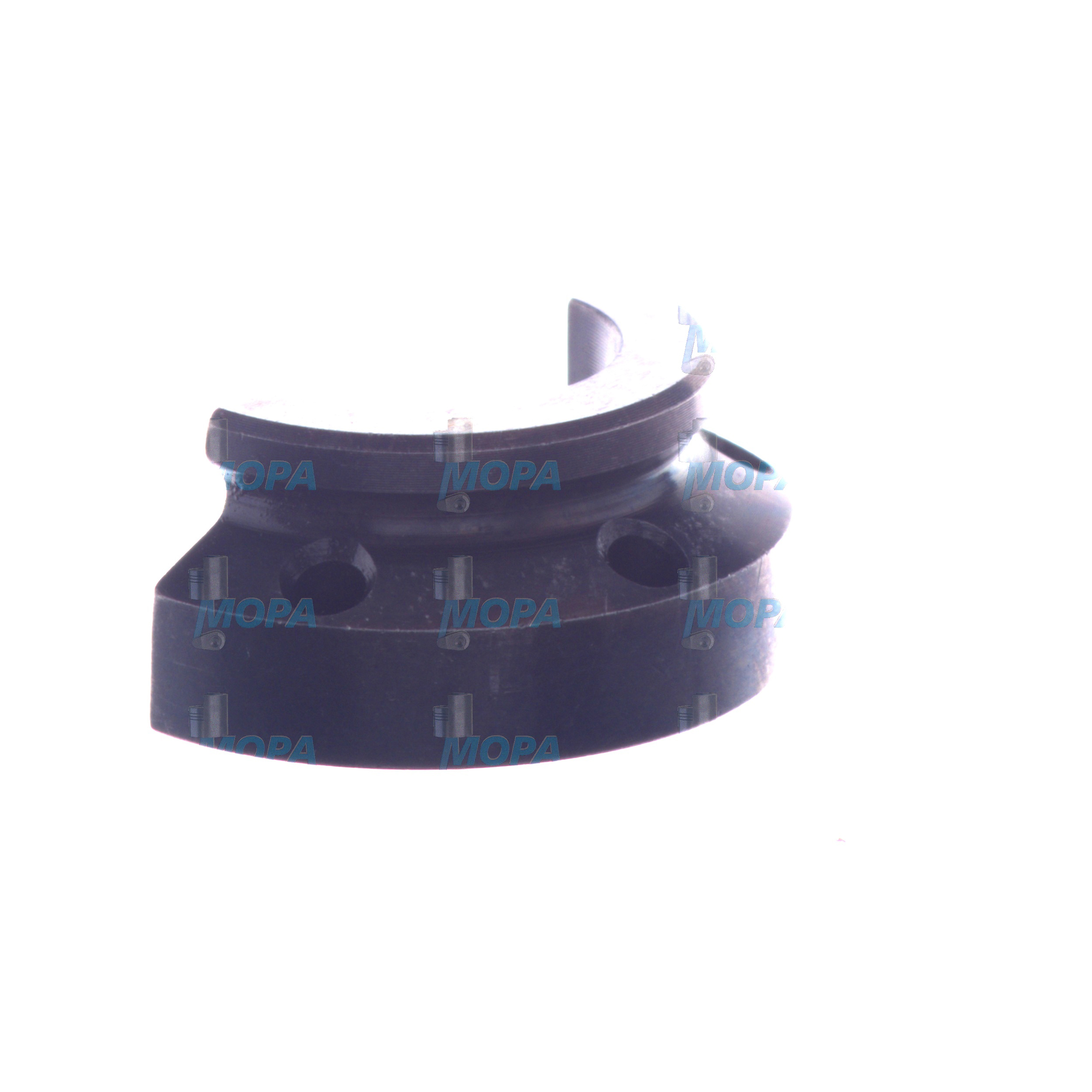

Engine bearings operate on the hydrodynamic principle: as the shaft rotates, a wedge of pressurized oil forms between the journal and the bearing surface, creating a fluid film that prevents metal-to-metal contact. The bearing shells are typically bi‑metal or tri‑metal constructions with a steel back for rigidity, a high-load intermediate layer (often copper-based or aluminum-based), and a soft overlay with excellent conformability and anti-seizure properties. Precision geometry—crush, eccentricity, and oil clearance—ensures film formation over a wide range of speeds, loads, and temperatures.

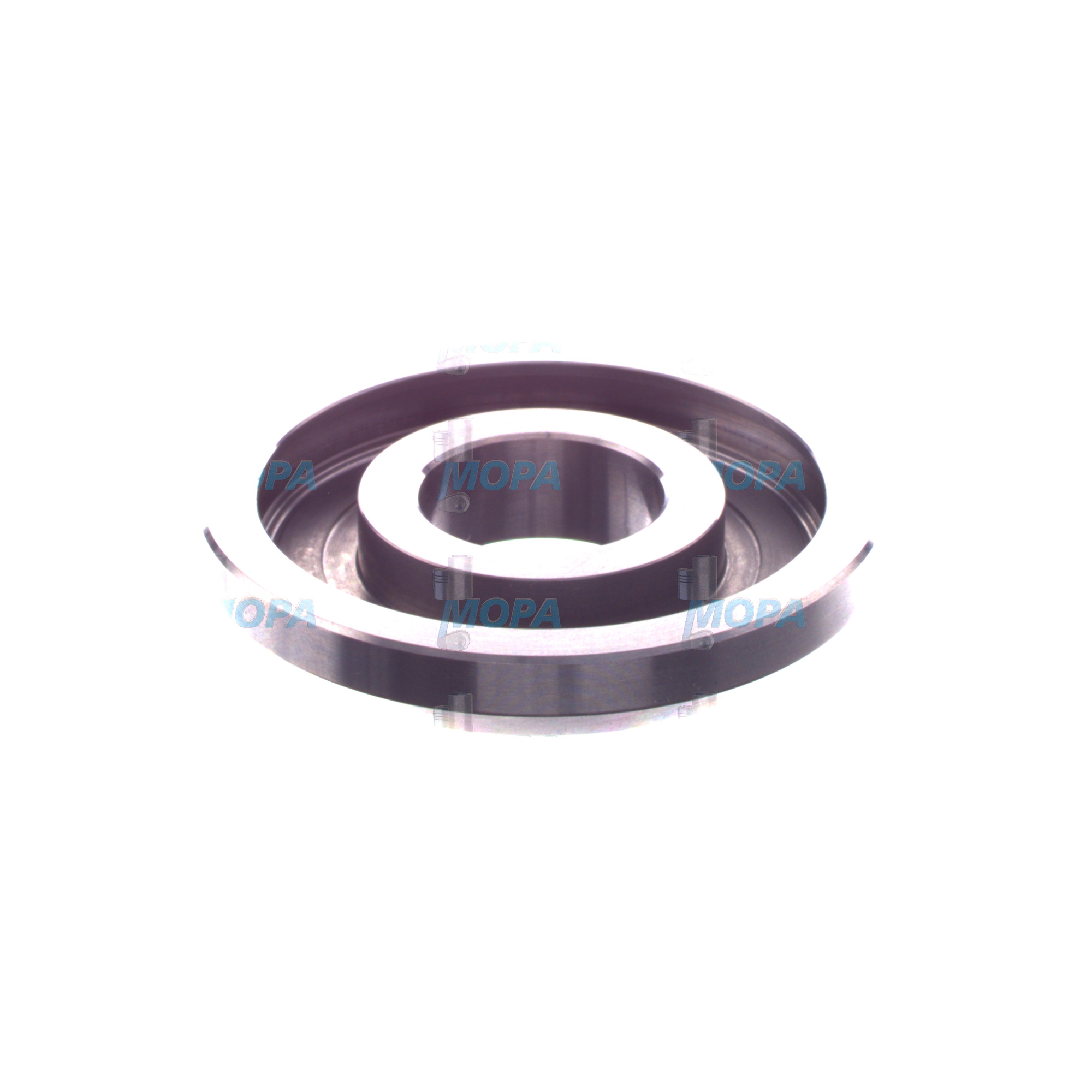

The axial location of the crankshaft is managed by the thrust bearing assembly, often realized as paired flanged shells or separate washers commonly referred to as a THRUST RING. In a THRUST RING marine engine configuration, these pads absorb axial forces originating from the propeller, helical gear trains, or coupling dynamics. The thrust surfaces feature oil grooves and reliefs that distribute lubricant and evacuate heat, preserving a stable film even during transient events such as maneuvering, load steps, or reversing. In a high-output THRUST RING diesel engine, the correct material pairing and surface finish of the thrust faces are critical to prevent wiping, scoring, and fretting at the thrust collar.

By holding end-float within tight limits, the thrust bearing prevents axial migration that would otherwise affect gear meshing, crankshaft position, and sealing interfaces. Stable end-float contributes directly to safer operation at high torque, reduces vibration, and safeguards timing accuracy. When sourced as THRUST RING OEM parts, dimensional tolerances and metallurgical specs are matched to the engine design, enabling consistent hydrodynamic behavior and predictable wear patterns.

Key characteristics and advantages of Bearings at a glance

· High fatigue strength for sustained high mean effective pressure

· Excellent conformability and embeddability to handle minor debris

· Optimized oil grooves and holes for stable hydrodynamic films

· Precisely controlled clearances to reduce friction and heat

· Robust anti-seizure and anti-scuff overlays for mixed-lubrication events

· Corrosion- and cavitation-resistant materials for marine fuels and oils

· Accurate axial control via thrust faces and THRUST RING assemblies

· Consistent geometry (crush, eccentricity) for secure seating and alignment

· Compatibility with condition monitoring (temperature, oil analysis)

· Long service intervals with predictable wear-in behavior

Importance for engine operation and service life

Bearings are among the most critical wear components in any engine. If journal or thrust bearings lose their hydrodynamic film due to incorrect clearance, oil starvation, or contamination, friction spikes and metal contact can occur within seconds. Consequences range from localized overlay fatigue and wiping to journal scoring, vibration, loss of oil pressure, or catastrophic seizure. Excessive axial wear at the thrust faces increases end-float, which can misalign gears, compromise shaft seals, and induce damaging loads on couplings and generators.

Common failure mechanisms include fatigue cracking in the intermediate layer, cavitation erosion at high-load zones, corrosion from acidic byproducts, and edge loading due to misalignment. Early warning signs are elevated bearing temperatures, metallic particles in oil analysis, abnormal end-float readings, and noise. Maintaining bearings in correct condition is therefore central to reliability, as they determine how effectively power is transmitted, how efficiently friction losses are managed, and how safely the engine copes with dynamic loads at sea or in continuous power applications.

Advantages of OEM spare parts suitable for Bearings and THRUST RING

Using OEM spare parts suitable for your bearing and THRUST RING positions ensures the exact geometry and material system specified by the engine designer. Micron-level tolerances for wall thickness, crush, and eccentricity are crucial to building the intended oil film and to maintaining correct end-float. The right overlays and surface treatments deliver the anti-seizure, embeddability, and fatigue resistance needed for modern fuels and high peak pressures. Oil groove patterns and chamfers are reproduced precisely so that lubrication and cooling match the engine’s hydrodynamic model.

Beyond performance, OEM spare parts suitable for bearings contribute to lower total cost of ownership. They reduce the risk of premature wear, minimize run-in times after overhaul, and help avoid secondary damage to expensive components such as crankshafts and gear trains. Traceability and documentation support compliance with class requirements and maintenance records. For purchasing teams and technical managers, this combination of predictable performance, durability, and documentation translates to fewer unscheduled stops and better budget control across the engine lifecycle.

MOPA – your partner for OEM parts: Bearings and THRUST RING solutions

MOPA is an experienced and reliable partner for OEM spare parts suitable for Bearings, including THRUST RING assemblies, for diesel and gas engines. We focus on speed in sourcing and delivery, ensuring that critical components reach your vessel or plant with minimal downtime. Quality is safeguarded through strict supplier selection, batch traceability, and documentation aligned with engine maker specifications. Our team supports you with part-number verification, dimensional checks, and technical cross-references to make procurement secure and straightforward.

Whether you manage a fleet of oceangoing vessels or a power plant with high utilization, MOPA provides fast quotations, dependable lead times, and secure logistics worldwide. From main and conrod bearings to thrust sets and specialized shells, we help you keep engines running efficiently and predictably.

Conclusion: THRUST RING Bearings and OEM parts for reliable engines

Bearings—together with the THRUST RING—are vital to controlling friction, loads, and axial movement in marine and diesel engines. Their design and condition directly influence efficiency, safety, and component longevity.

OEM spare parts suitable for Bearings provide the dimensional accuracy, metallurgy, and lubrication features needed for stable operation and extended service life. With MOPA as your partner, you secure fast, high-quality access to the right OEM components for dependable performance.