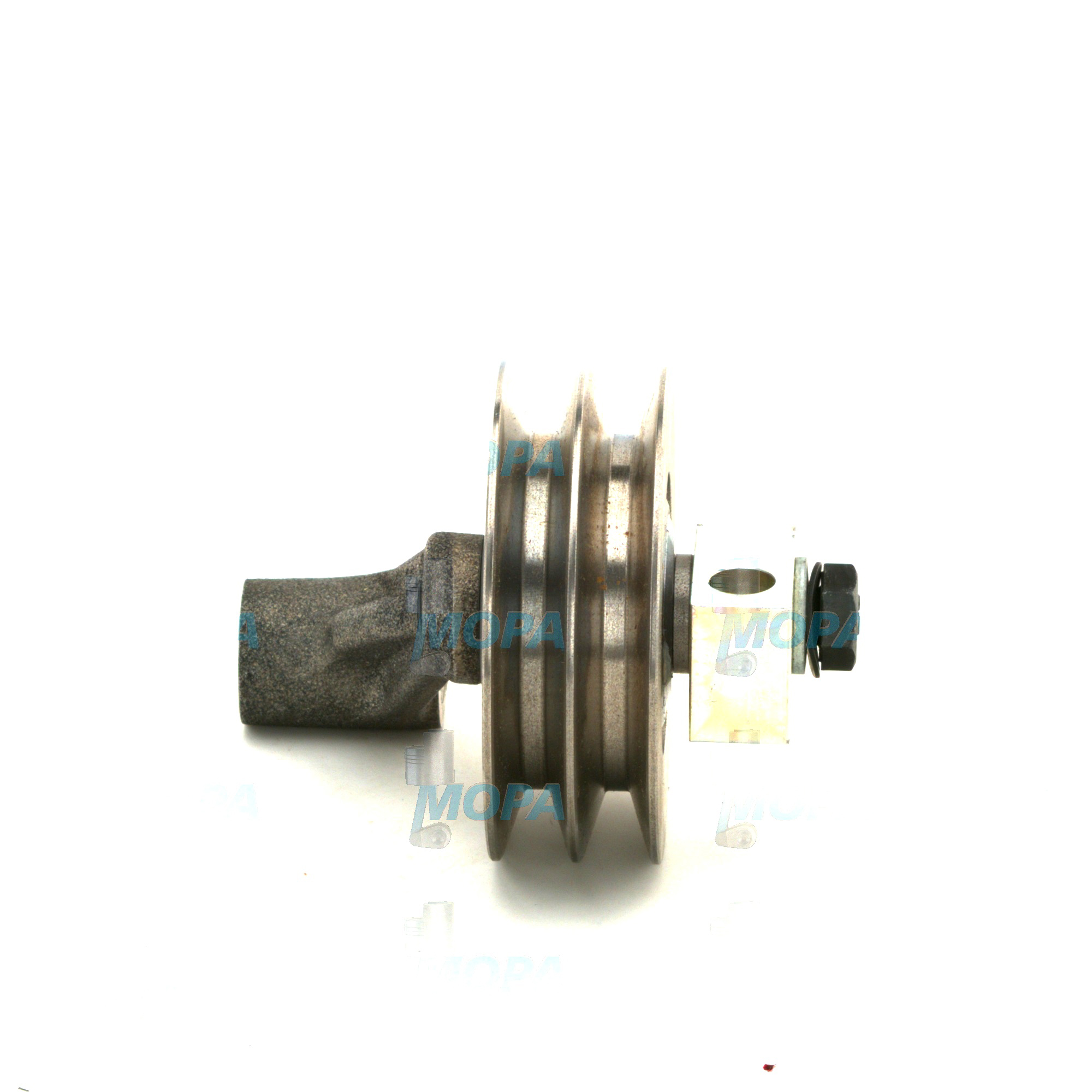

TENSION PULLEY Belt Drive Parts for Marine and Diesel Engines

Belt drive parts form a critical subsystem in marine and industrial powertrains, ensuring that essential auxiliaries run exactly when the engine demands them. This article category covers components such as the TENSION PULLEY, idler pulleys, multi-rib and V-belts, drive pulleys, and their mounting hardware. In both marine engine rooms and land-based plants, these parts transmit power from the crankshaft to alternators, coolant pumps, seawater pumps, air compressors, and fans. Without a stable and precisely controlled belt drive, even a robust diesel engine cannot deliver reliable electricity, cooling, or pneumatic capacity—functions that are indispensable for vessel safety and productive operations.

As operating environments become tougher—higher ambient temperatures, fluctuating loads, and long service intervals—belt drive parts must maintain alignment, friction, and belt wrap around accessory pulleys. A high-quality TENSION PULLEY in a diesel engine or marine engine maintains the correct preload and compensates for belt stretch and thermal expansion, directly influencing efficiency and uptime.

Technical function: How Belt Drive Parts and the TENSION PULLEY enable dependable power transmission

The belt drive converts crankshaft rotation into auxiliary work. The TENSION PULLEY applies a controlled, consistent force to the belt so that the ribs engage properly with the pulley grooves. In modern multi-rib (serpentine) systems, the tensioner assembly often integrates a spring mechanism and a damper; the TENSION PULLEY interfaces with this mechanism through a sealed bearing and a precisely machined running surface. The result is stable belt tension across engine speed ranges, rapid response to transient load steps, and reduced vibration. In a marine engine, this stability keeps seawater and jacket-water pumps within the optimal flow band—vital for preventing thermal stress. In a diesel engine, it ensures alternator output remains within specification for battery charging and onboard systems.

On the micro level, the TENSION PULLEY controls belt span vibration modes, minimizing whip and resonance that would otherwise induce slip and heat. Controlled tension improves wrap angle on driven pulleys, reducing the torque required to transmit power and lowering belt temperature. Bearing quality in the TENSION PULLEY—lubrication chemistry, raceway hardness, and sealing—directly affects service life, especially in humid, saline, or oily atmospheres typical of marine machinery spaces. When sourced as TENSION PULLEY OEM parts, dimensional accuracy holds alignment across brackets and frames, keeping runout low and belt tracking true.

- · Consistent tension for optimal belt grip and low slip

- · Damping of belt vibrations to protect bearings and brackets

- · Precision surfaces for reduced belt wear and heat

- · Sealed bearings engineered for long service in harsh environments

- · Corrosion-resistant materials suited to marine engine duty

- · Accurate alignment and runout control for efficient power transfer

- · Compatibility with multi-rib and V-belt configurations

Importance for engine operation: Why Belt Drive Parts matter for reliability and service life

Even minor deviations in belt tension or pulley alignment propagate quickly into performance losses. Under‑tension leads to belt slip, glazing, and noise; auxiliary speeds fall, causing undercharging, reduced coolant flow, and rising coolant temperatures. Over‑tension accelerates bearing and shaft wear in alternators and pumps, increases drive losses, and can cause premature belt cracking. A worn or rough TENSION PULLEY surface generates heat spots and accelerates belt rib degradation. In severe cases, a misaligned or seized pulley can throw the belt, resulting in an immediate loss of cooling and electrical power—an unacceptable risk for ship propulsion or critical gensets.

Early indicators include black belt dust in guards, frayed edges, rib cracking, chirp or squeal on start, and elevated bearing temperatures measured with a handheld IR device. Maintenance best practice includes periodic visual inspection, belt frequency or force measurement, and verification of pulley runout. Maintaining high-quality belt drive parts, especially the TENSION PULLEY on diesel engine and marine engine applications, directly translates into longer component life, fewer unplanned stoppages, and predictable maintenance cycles.

Advantages of OEM spare parts suitable for Belt drive parts

Using OEM spare parts suitable for belt drive parts ensures that geometry, materials, and assembly tolerances match engine-maker specifications. That precision is decisive for performance and lifecycle cost. The TENSION PULLEY OEM parts come with engineered spring rates (when part of an automatic tensioner system), calibrated damping, and validated bearing loads, all tuned to the specific belt profile and accessory layout. This reduces energy loss, stabilizes auxiliary speeds, and protects connected equipment.

Beyond fit and function, the right surface finishes, coatings, and seal designs resist corrosion and contamination, maintaining low friction and extending replacement intervals. Dimensional conformity streamlines installation, shortens downtime, and reduces the risk of misalignment. For operators focused on total cost of ownership, OEM spare parts suitable for belt drive parts deliver predictable service life and stable budgeting over long deployment cycles.

TENSION PULLEY OEM parts: Performance, reliability, budget, and service life

- Performance: Correct belt preload preserves torque capacity and electrical output under peak hotel loads or maneuvering. - Reliability: Validated bearings and damping minimize heat and vibration, reducing failure modes. - Budget: Longer intervals and faster fit-up lower labor and parts consumption over time. - Service life: Materials and coatings resistant to salt, oil mists, and temperature cycles keep the drive running across extended intervals.

MOPA as a partner for TENSION PULLEY and Belt Drive Parts

MOPA is an experienced and reliable partner for OEM spare parts suitable for belt drive parts, including the TENSION PULLEY for diesel and gas engines. Customers benefit from rapid availability, stringent quality control, and secure, traceable handling throughout the supply chain. Whether supporting a propulsion plant, an auxiliary genset, or a shore-based power unit, MOPA streamlines sourcing with documentation, compatibility checks, and technical clarity.

MOPA strengths in TENSION PULLEY OEM parts for marine and diesel engines

- Speed: Efficient logistics and stock coverage minimize engine downtime. - Quality: Parts aligned with engine-maker specs and proven in demanding duty cycles. - Security: Transparent processes and documentation support compliance and audit requirements for marine operations.

Conclusion: TENSION PULLEY and Belt Drive Parts keep engines mission-ready

Belt drive parts are essential to safe, efficient operation, and the TENSION PULLEY sits at the heart of belt stability in both marine engine and diesel engine applications. Selecting OEM spare parts suitable for belt drive parts protects performance, extends service life, and keeps budgets predictable. With MOPA, operators gain a dependable source for quality and speed in the trade of OEM parts for diesel and gas engines.