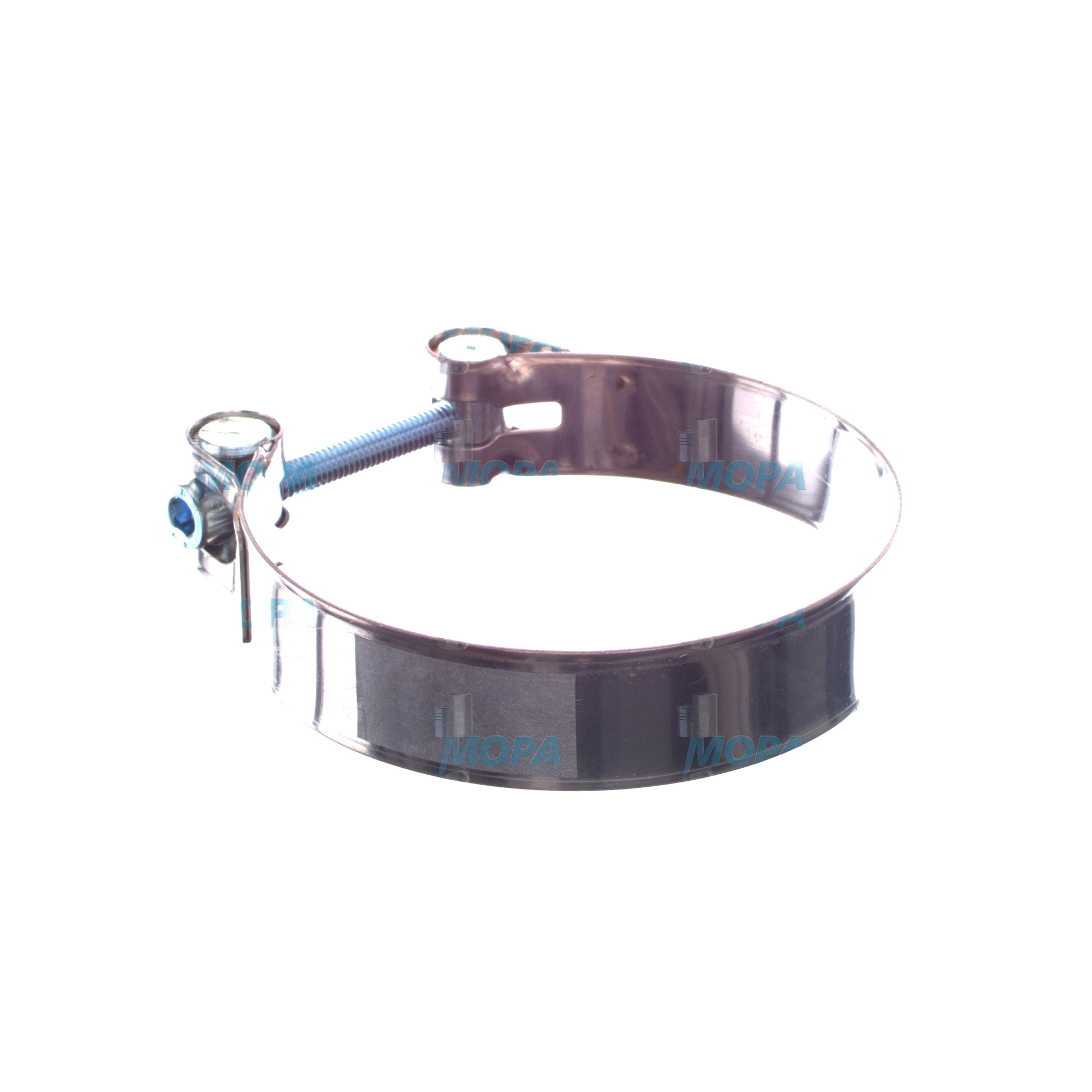

HOSE CLAMP Clamps for Marine and Diesel Engines

Clamps are compact, high-load fastening components that create a secure, leak-tight connection between hoses and fittings in engines. From coolant and lubrication circuits to charge-air, fuel, and ventilation lines, clamps keep fluid and air paths sealed under pressure, vibration, and thermal cycling. In marine engine rooms and power plant installations, their reliability is critical: a single loose hose joint can compromise performance, increase fuel consumption, or trigger costly downtime. Within this category, the HOSE CLAMP stands out as a primary solution for hose-to-pipe and hose-to-spigot joints across diesel and gas engines.

Engineered in a range of materials, widths, and tightening mechanisms, clamps match the duty of the system they serve—low-pressure coolant, high-temperature oil, or high-boost charge-air. Precision selection and correct torque yield consistent sealing force, prevent hose damage, and extend service intervals.

Technical function of HOSE CLAMP in marine and diesel engine systems

The core function of a HOSE CLAMP is to apply uniform radial compression so the hose’s elastomer layer conforms to the fitting and any bead or barb, producing a gas- or liquid-tight seal. In a diesel engine, this uniform load prevents coolant seepage, oil mist, and boost leaks; in a marine engine, it resists salt-laden humidity, dynamic hull-induced vibration, and frequent thermal swings. Typical designs include worm-drive clamps for general service, T-bolt clamps for high-pressure or charge-air hoses, and constant-tension (spring) clamps that automatically track temperature-driven dimensional changes.

Performance hinges on the interplay of band width, material grade, thread form, and inner surface finish. AISI 304 stainless steel balances strength and corrosion resistance for machinery spaces; AISI 316 is preferred in aggressive marine atmospheres. Rounded, deburred edges and lined bands protect the hose cover from cutting, while defined tightening torque (e.g., approx. 3–5 Nm for many worm-drive sizes; higher for T-bolt formats—always follow the specification) helps achieve sealing load without crushing the hose. Quality HOSE CLAMP OEM parts are validated to deliver stable clamping force over thousands of thermal and vibration cycles, protecting engine efficiency and component life.

Key characteristics and advantages of clamps

· Corrosion-resistant steel options (AISI 304/316) for marine duty.

· Band widths selected to match hose size and system pressure.

· Rounded, deburred edges to safeguard hose covers.

· Smooth or lined inner surfaces to prevent hose extrusion.

· Constant-tension options for thermal cycling and cold-flow compensation.

· Defined torque windows for repeatable sealing force.

· High vibration resistance for diesel and gas engine environments.

· Broad media compatibility: coolant, fuel, oil, charge air.

Why HOSE CLAMP reliability is vital for engine operation and service life

Clamps are small, but their impact is large. Loss of clamping force—through corrosion, thread stripping, over-tightening, or fatigue—can cause micro-leaks that aerate coolant, reduce pump efficiency, and elevate operating temperatures. On turbocharged engines, a minor charge-air leak at a coupler results in lower boost, higher exhaust temperatures, and increased fuel burn. Fuel or oil weeping risks contamination, fire hazards, and environmental incidents, especially at sea.

Incorrect clamp selection can be equally damaging. Bands that are too narrow or with sharp edges can cut into hose covers, initiating premature hose failure. Oversized clamps bottom out before sealing; undersized clamps overload the hose and deform it. In marine applications, chloride stress and galvanic effects accelerate deterioration if material compatibility is overlooked. Routine inspection should check for rust bloom, band deformation, thread damage, and loss of torque retention. Timely replacement of critical HOSE CLAMP connections maintains engine uptime, safeguards crew, and protects adjacent components from heat and spray.

Advantages of OEM spare parts suitable for HOSE CLAMP

Choosing OEM spare parts suitable for clamps ensures each component matches the intended clamping load, band geometry, and material specification for the engine model. This precision translates into measurable results: stable sealing force under vibration, consistent torque-to-tension behavior, and reduced risk of hose damage. Traceable materials and process control mean the stainless grade, band hardness, and coating are exactly as specified, delivering predictable corrosion resistance in marine service.

For purchasers and fleet managers, the benefits extend to total cost of ownership. Correctly engineered HOSE CLAMP OEM parts reduce unplanned stoppages, leak-related cleanups, and frequent rework. They also protect hoses and fittings, extending replacement intervals. Compliance with relevant standards (e.g., SAE J1508 for clamps) and alignment with engine-builder layouts make installation straightforward and repeatable across vessels and sites, supporting consistent maintenance outcomes and inventory clarity.

· Dimensional fidelity for the exact hose OD and fitting bead geometry.

· Verified torque specs aligned with target sealing load.

· Material traceability and corrosion performance suited to marine engine rooms.

· Lower downtime risk and longer hose service life for better budget control.

· Streamlined maintenance through consistent fit across engine variants.

MOPA as your partner for OEM spare parts for Clamps and HOSE CLAMP needs

MOPA is an experienced, reliable partner for OEM spare parts for Clamps, delivering fast access to HOSE CLAMP solutions for diesel and gas engines. Our focus is on speed, quality, and security throughout the supply chain—from sourcing and documentation to packaging and delivery—so critical connections are restored without delay. Whether you operate a marine engine fleet, a power plant, or industrial generator sets, MOPA supports you with technical clarity, matching parts to application requirements and environmental conditions.

We help standardize clamp specifications across assets, consolidate shipments to reduce lead times, and ensure that the OEM parts you receive integrate seamlessly with your systems. The result is safer operation, reliable sealing in harsh environments, and predictable maintenance planning.

Conclusion: HOSE CLAMP performance that protects engines

Clamps are fundamental to safe, efficient engine operation, and the HOSE CLAMP is the workhorse for sealing hose connections in marine and diesel engines. Selecting OEM spare parts suitable for Clamps secures stable sealing force, protects hoses and fittings, and supports uptime and budget targets.

Partner with MOPA to source the right HOSE CLAMP OEM parts quickly and confidently, and keep your engines performing at their designed efficiency and reliability levels.