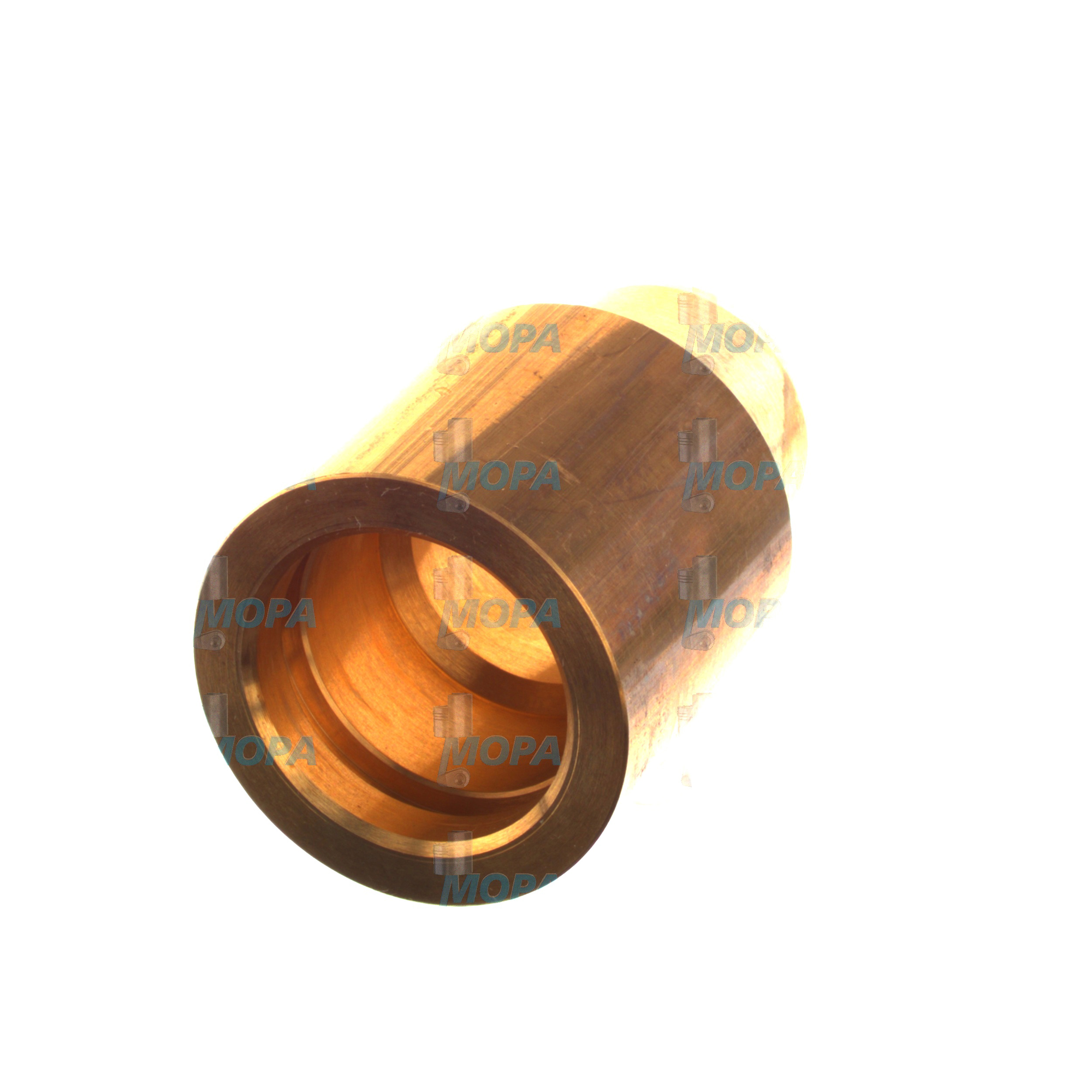

COUPLING SLEEVE Clutches for High-Duty Diesel and Marine Engines

Clutches are critical drivetrain components that connect and disconnect rotating assemblies, allowing engines to transmit torque to gearboxes, generators, pumps, or propeller shafts on demand. In heavy-duty applications such as marine propulsion, power generation, and industrial drives, clutch assemblies ensure controlled engagement, protect downstream equipment from shock loads, and enable efficient power flow across varying operating conditions. Within many clutch architectures, the COUPLING SLEEVE is a core element that translates actuation force into a positive, centered connection between input and output.

Modern clutch systems range from wet multi-disc units to toothed (jaw) clutches and torsionally damped solutions. Regardless of design, their purpose remains constant: reliable torque transfer with minimal heat losses and precise engagement. In these assemblies, the COUPLING SLEEVE often provides the sliding spline or dog-tooth interface that locks shafts together, aligning rotating members and maintaining concentricity—key to long service intervals and stable performance.

Technical Function: How Clutches and the COUPLING SLEEVE Operate in a Diesel Engine or Marine Engine

A clutch enables selective coupling of the engine’s crankshaft to a driven member. In friction clutches, stacked discs are pressed together to create a torque path; in jaw/toothed clutches, interlocking teeth provide a slip-free connection. The COUPLING SLEEVE in a diesel engine or marine engine typically moves axially along splines to engage mating teeth or friction packs. Actuation can be hydraulic, pneumatic, or electromechanical, converting control signals into precise sleeve motion. The result is smooth torque handover, reduced torsional shock, and optimized driveline efficiency.

In heavy marine gearboxes, a COUPLING SLEEVE marine engine setup centers the sleeve via pilot diameters and guided splines to avoid micro-misalignment that would otherwise cause fretting and noise. Correct sleeve geometry (tooth form, lead-in chamfers, hardness) promotes quick synchronization and repeatable engagement times. In generator sets, a friction clutch with a guided COUPLING SLEEVE OEM parts solution helps minimize spin losses during idle and prevents heat build-up under partial load by maintaining accurate clamp loads and oil film control in wet systems.

Key characteristics and advantages of clutches with a COUPLING SLEEVE

- · High torque density with compact envelope

- · Controlled engagement to limit shock loads

- · Precise axial guidance for consistent alignment

- · Low wear rates with correct lubrication and materials

- · Fast actuation for responsive load changes

- · Supports safe disconnection in fault scenarios

- · Compatible with hydraulic or pneumatic controls

- · Serviceable components for predictable maintenance

Importance for Reliable Engine Operation and Service Life

Clutches are central to uptime. When the COUPLING SLEEVE and mating interfaces are in proper condition, engagement is repeatable and low in vibration, protecting gears, shafts, and bearings from excessive loads. Stable torque transfer reduces heat generation, conserving oil condition and safeguarding seals and friction materials. In propulsion, this translates into smooth manoeuvring and fuel-efficient acceleration; in power generation, it means stable frequency control and quick synchronization.

If the clutch or COUPLING SLEEVE suffers wear, contamination, or misalignment, a cascade of problems can follow. Common issues include tooth chipping on jaw clutches, spline fretting corrosion, glazing or hot spotting of friction plates, delayed engagement, chatter, and thermal fade under heavy load. These faults drive up fuel consumption and can escalate into gearbox damage, premature bearing failure, and unplanned stoppages. Periodic inspection of sleeve teeth, spline fit, and actuation response—alongside oil cleanliness checks in wet systems—prevents small deviations from becoming costly downtime.

Advantages of OEM Spare Parts Suitable for Clutches and the COUPLING SLEEVE

Choosing OEM spare parts suitable for clutches ensures dimensional accuracy, material integrity, and proven compatibility with the engine platform. The COUPLING SLEEVE OEM parts route delivers consistent spline profiles, controlled tooth hardness, and correct surface finishes—factors that directly affect engagement quality, noise, and wear. Precision heat treatment and alloy selection (e.g., nitrided alloy steels) help resist pitting and micro-welding in high-load, low-speed marine manoeuvres and during frequent start-stop duty.

Beyond fit and function, OEM spare parts protect budgets by extending service intervals, reducing rework, and shortening commissioning time. Verified friction materials (sintered, paper, carbon) hold their coefficient of friction within spec across temperature cycles, while tested seal kits and actuators maintain consistent pressure ramps. The result is lower lifecycle cost, fewer unscheduled interventions, and stable performance across diesel engines, gas engines, and hybrid drivetrain configurations.

- · Accurate tolerances for seamless drop-in replacement

- · Validated metallurgy and heat treatment for long wear life

- · Consistent engagement characteristics under load

- · Reduced vibration and noise through correct geometry

- · Predictable maintenance planning and lower downtime

- · Full traceability and technical documentation

MOPA: Fast, Secure Supply of OEM Parts for Diesel and Gas Engine Clutches

MOPA is an experienced partner for sourcing OEM spare parts suitable for clutches and the COUPLING SLEEVE across leading diesel and gas engine platforms. Customers benefit from rapid response, short lead times, and careful packaging that preserves critical surfaces and tolerances. MOPA’s established supplier network, batch traceability, and inspection procedures add security to every transaction, from inquiry to delivery.

Whether you operate a marine engine, a power-plant genset, or an industrial compressor drive, MOPA supports your operation with technically correct selections, kitting for planned overhauls, and global logistics. The focus is simple: deliver the right OEM parts quickly and reliably so your clutches engage cleanly, your COUPLING SLEEVE interfaces last longer, and your equipment stays productive.

Conclusion

Clutches—supported by a precisely engineered COUPLING SLEEVE—are essential to efficient torque transfer, smooth engagement, and the long-term health of diesel and marine drivetrains. Selecting OEM spare parts suitable for clutches safeguards performance and helps you control lifecycle costs while maximizing uptime.