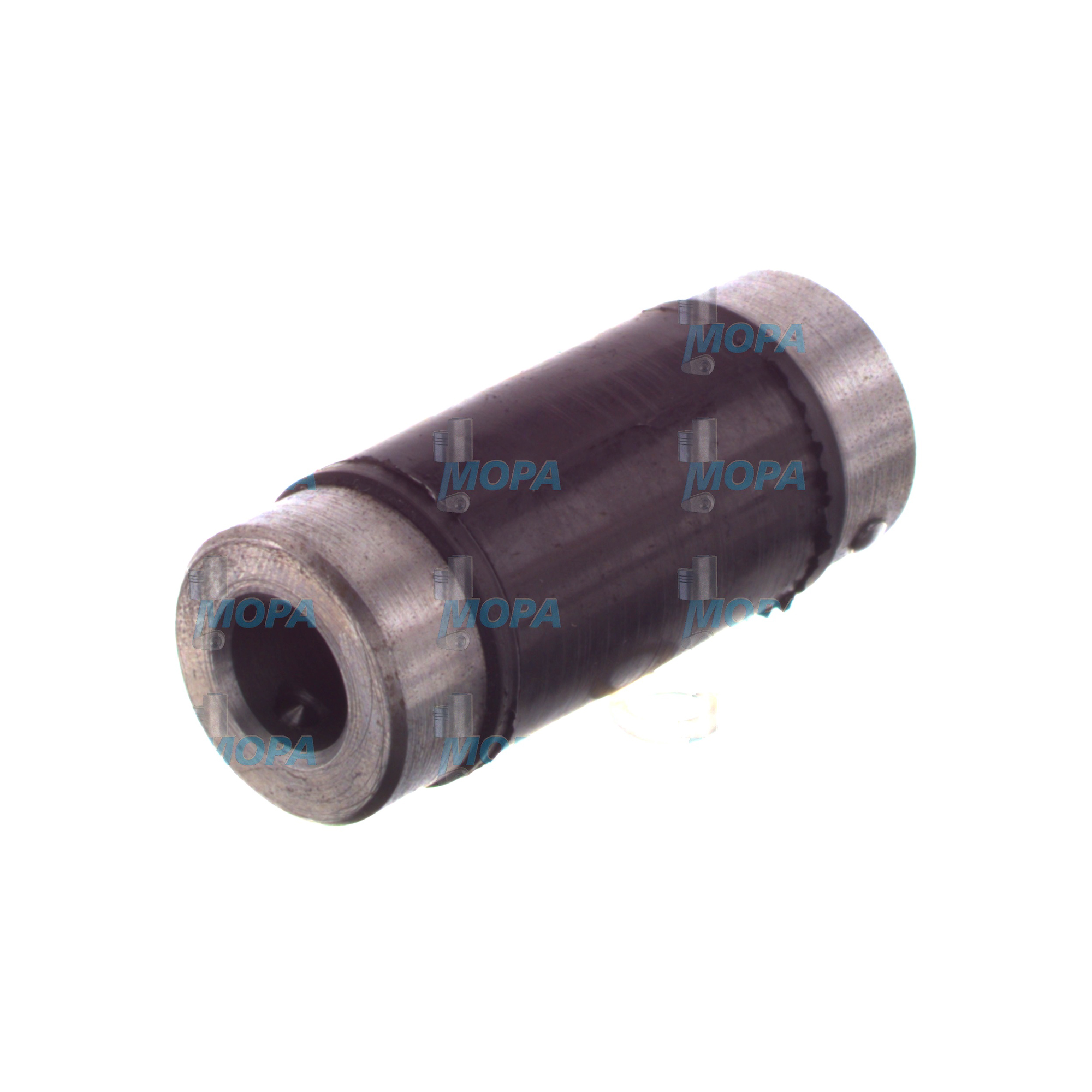

RUBBER BEAD COUPLING and Clutches for High-Performance Marine and Diesel Engines

Clutches are critical powertrain components that engage and disengage torque between the engine and the driven system—gearbox, propeller shaft, generator, or pump. In marine and industrial diesel engine applications, clutches enable controlled power transfer, protect against overload, and support smooth operation during maneuvering and load changes. In many drivetrains, a RUBBER BEAD COUPLING is paired with the clutch to damp torsional vibrations and isolate shocks, ensuring lower stress on shafts, bearings, and gearsets. Together, clutches and torsionally elastic couplings form a robust link that preserves performance, efficiency, and safety in demanding duty cycles.

How Clutches Work in a Marine Engine: Function and the Role of RUBBER BEAD COUPLING

A clutch transmits torque from the crankshaft to the transmission via friction interfaces. In a typical marine diesel engine setup, multi-plate friction discs—often steel on one side and friction-lined on the other—are clamped by springs or hydraulics/pneumatics to create a solid, slip-free connection once engaged. During engagement, the clutch allows controlled slip to synchronize speeds, absorb initial torque spikes, and prevent driveline shock. Thermal capacity, friction coefficient stability, and plate flatness determine how smoothly and reliably the clutch performs under repeated cycles.

Actuation can be pneumatic or hydraulic, with precise control over pressure and engagement timing to match vessel maneuvers and generator load steps. Wet clutches rely on lubrication to manage heat and wear; dry clutches prioritize simplicity and high friction coefficients but require careful thermal management. Alignment, spline fit, and correct clamp load are vital to avoid hot spots, glazing, or premature lining wear.

Downstream or upstream of the clutch, a RUBBER BEAD COUPLING for a marine engine driveline provides torsional elasticity. It filters firing pulses from the diesel engine, reduces resonance, and minimizes vibration transmitted to the gearbox or shaft line. When specified correctly, a RUBBER BEAD COUPLING OEM parts solution complements the clutch by smoothing engagement, extending component life, and lowering noise levels. The result is a drivetrain tuned for torque capacity, thermal resilience, and vibration control across the vessel’s operating envelope.

- · High torque density for compact installations

- · Controlled engagement to protect gear teeth and shafts

- · Stable friction coefficients across temperature ranges

- · Thermal capacity designed for frequent clutch-in cycles

- · Compatibility with RUBBER BEAD COUPLING to reduce torsional peaks

- · Pneumatic/hydraulic actuation for precise modulation

- · Service-friendly plate stacks and accessible wear indicators

- · Compliance with common SAE flywheel housings and spline standards

Why Clutches Matter for Reliability and Service Life

Clutches are central to propulsion availability and power generation uptime. If a clutch is worn, misadjusted, or thermally damaged, symptoms emerge quickly: slipping under load, delayed engagement, vibration, heat discoloration, and abnormal noise. Persistent slip raises oil temperatures in wet systems, degrades friction materials, and can trigger accelerated wear of mating components. In severe cases, plate cracking, loss of clamp force, or spline fretting can lead to unexpected downtime—risking loss of propulsion, schedule disruption, or auxiliary power interruptions.

Properly specified and maintained clutches stabilize the drivetrain, maintain fuel efficiency by minimizing parasitic losses, and protect costly components such as bearings and gearboxes. Coordinating the clutch with a correctly sized RUBBER BEAD COUPLING for a diesel engine also prevents operation at torsional resonance speeds, lowering cyclic stress and extending the interval between overhauls.

Advantages of OEM Spare Parts Suitable for Clutches and RUBBER BEAD COUPLING

Using OEM spare parts suitable for clutches preserves the engineered torque rating, thermal performance, and balance of the assembly. Friction plates, pressure plates, springs, seals, and actuation components manufactured to engine-builder specifications maintain the designed clamp load and consistent friction behavior. Likewise, a RUBBER BEAD COUPLING OEM parts solution ensures the correct rubber compound hardness, bead geometry, and damping characteristics, so the driveline retains its vibration profile and alignment tolerances.

For purchasers and technical managers, the benefits are measurable: predictable engagement behavior after maintenance, reduced commissioning time, and fewer callbacks due to shudder or slip. Correct materials—sintered, carbon, or specialized paper linings—deliver the stated life at the expected oil temperature and contamination limits. Accurate hub and spline dimensions prevent micro-movement that causes fretting and wear. Together, these factors protect budget and extend service life by preventing repeat repairs and secondary damage to gears, bearings, and seals.

Selection Checklist for Diesel Engine Clutches and RUBBER BEAD COUPLING OEM Parts

- · Confirm torque, speed, and duty cycle (maneuvering vs. continuous load)

- · Match friction lining type to lubricant, temperature, and engagement frequency

- · Verify actuation pressure, response time, and control interface

- · Check spline/hub geometry, flywheel housing, and pilot dimensions

- · Specify RUBBER BEAD COUPLING stiffness and damping for the torsional model

- · Ensure corrosion resistance and sealing for marine environments

- · Request traceable documentation for material and dimensional conformity

RUBBER BEAD COUPLING and Clutches: MOPA as Your OEM Partner

MOPA is an experienced and reliable partner for OEM spare parts suitable for clutches and RUBBER BEAD COUPLING across diesel and gas engine platforms. We focus on speed, quality, and security in the trade of OEM parts—supporting shipowners, yards, and operators with responsive sourcing and technically correct selections. Our network enables rapid delivery of friction plates, complete clutch packs, actuation components, and coupling elements matched to your engine model and gearbox.

From troubleshooting slip or vibration issues to planning dry-dock overhauls, MOPA provides application-driven support that shortens downtime and safeguards drivetrain performance. With precise parts identification and consistent quality, your fleet benefits from repeatable results, stable maintenance intervals, and dependable propulsion or auxiliary power.

Conclusion: Clutches and RUBBER BEAD COUPLING Keep Power Trains Efficient

Clutches are indispensable for controlled power transfer and drivetrain protection, while a properly matched RUBBER BEAD COUPLING helps tame torsional vibration in marine and diesel engine applications. Choosing OEM spare parts suitable for clutches and coupling elements preserves performance, reliability, budget control, and long service life.