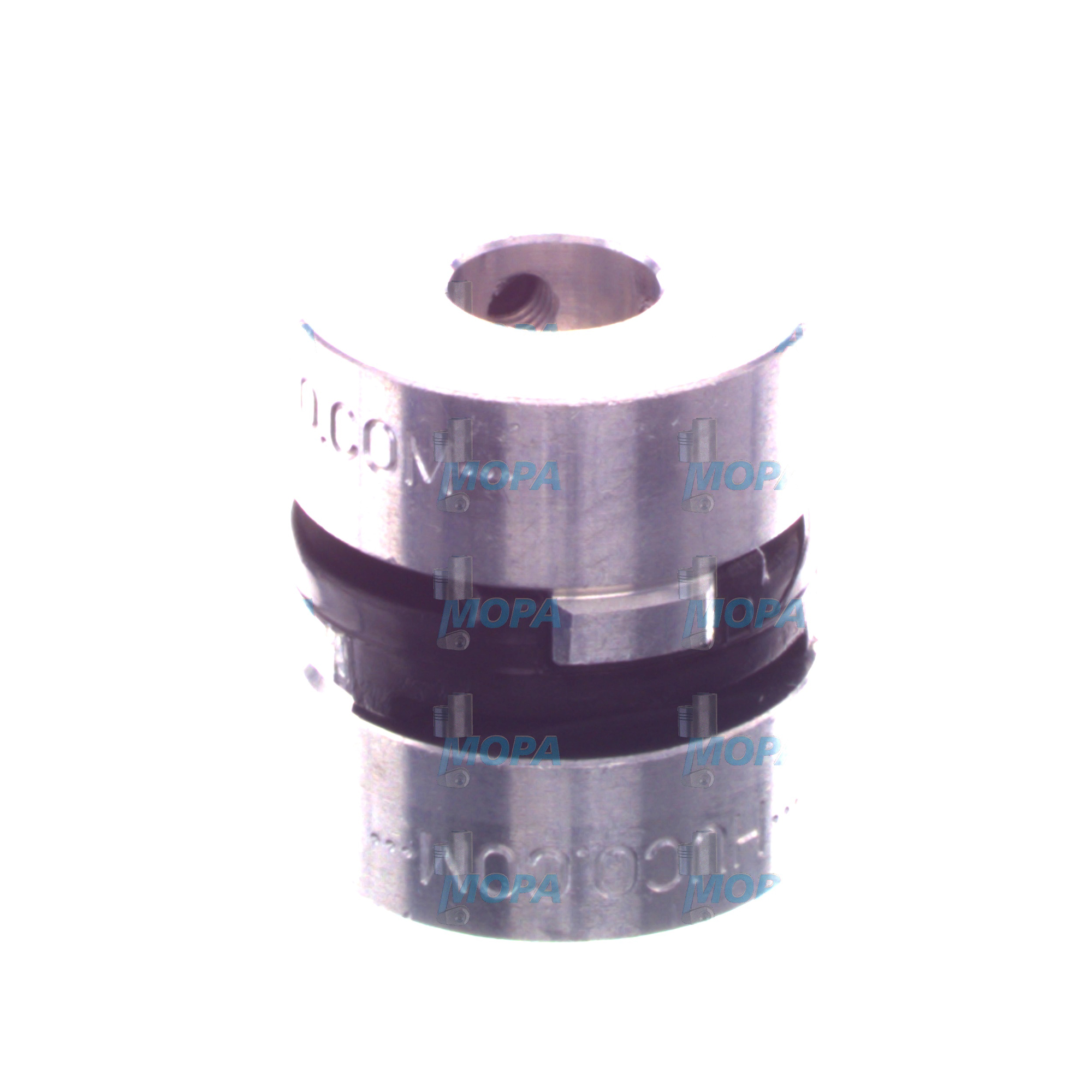

SHAFT COUPLING integration for Clutches in marine and diesel engine drivetrains

Clutches are critical torque-transmission components that engage and disengage power between an engine and the driven system—gearbox, propeller shaft, alternator, or compressor. In heavy-duty diesel and gas engines, especially in marine engine environments, clutches determine how smoothly power is delivered, how efficiently energy is transferred, and how equipment is protected from shock loads. Their interaction with the SHAFT COUPLING is central to drivetrain alignment, vibration control, and overall reliability. For purchasers and technical decision-makers, selecting the right clutch configuration and maintaining it with precise, high-grade components is essential to uptime and lifecycle cost control.

Technical function of Clutches and the SHAFT COUPLING interface

Within an engine-driven line, the clutch sits between the power source and the transmission or driven equipment. In a typical marine engine setup, torque flows from the crankshaft, through a flexible SHAFT COUPLING, into the clutch, and onward to the gearbox and propeller. The clutch assembly—pressure plate, friction discs, intermediate plates, hub/spline, release bearing, and actuation system (hydraulic or pneumatic)—controls engagement. When actuated, axial force compresses the friction pack, generating the normal force required to transmit torque without slip. When released, the drive is decoupled, enabling safe starts, gear changes, and controlled stops.

Performance hinges on friction material stability, plate flatness, spring or diaphragm characteristics, and cooling capability (for wet clutches). In high-inertia applications, the clutch must absorb and dissipate heat from transient slip while maintaining a stable coefficient of friction. The SHAFT COUPLING for marine engine or diesel engine applications complements the clutch by accommodating angular and axial misalignment and damping torsional vibrations, reducing stress on the friction pack and gearbox. Correct pairing of clutch geometry with the SHAFT COUPLING OEM parts ensures predictable engagement, minimal shock, and reduced wear across the drivetrain.

- · High torque capacity with stable friction characteristics.

- · Controlled engagement for reduced shock loads and smooth starts.

- · Compatibility with flexible SHAFT COUPLING to manage misalignment and vibration.

- · Precise hub and spline tolerances for efficient torque transfer.

- · Wet or dry configurations to suit duty cycle and thermal loads.

- · Hydraulic or pneumatic actuation for accurate, repeatable control.

- · Durable plates and linings designed for extended service intervals.

Importance of Clutches for engine operation and service life

A well-specified and well-maintained clutch preserves the integrity of the entire drivetrain. Proper engagement avoids gear tooth impact, protects bearings, and minimizes thermal stress. By moderating start-up torque and isolating torsional oscillations in partnership with the SHAFT COUPLING, clutches help safeguard gearboxes, engine mounts, and propeller shafts, supporting efficiency and lower fuel consumption.

Conversely, a worn or out-of-spec clutch increases slip and heat, which can glaze friction linings, warp plates, and degrade lubricants in wet systems. Operators may see uneven engagement, chatter, loss of thrust or electrical output, rising exhaust temperatures from elevated engine load, and vibration that propagates to the SHAFT COUPLING and gearbox. Left unchecked, these symptoms can develop into broken damper springs, cracked hubs, bearing failure, and unplanned downtime. Routine inspection—measuring friction lining thickness, checking plate runout and surface condition, verifying actuation pressure, and monitoring temperature—extends service life and keeps propulsion and power generation reliable.

Advantages of OEM spare parts suitable for Clutches

Using OEM spare parts suitable for clutches preserves the engineered balance between torque capacity, thermal behavior, and engagement quality. Friction discs, pressure plates, diaphragm springs, and release bearings produced to OEM drawings deliver the exact material mixes, heat treatments, and tolerances intended for the engine and duty profile. That precision translates into consistent engagement pressures, stable friction coefficients across temperature, and correct contact geometry, reducing setup time and the risk of early wear.

For purchasers managing total cost of ownership, the benefits are clear: faster installation due to perfect fit, predictable service intervals, and less collateral wear on adjoining components such as the SHAFT COUPLING and gearbox. OEM parts maintain spline fit and concentricity, minimize runout, and align with the thermal and load ratings specified for diesel and gas engines. The result is sustained performance, reliable operation under peak loads, and optimized budgets through avoided rework and reduced downtime.

MOPA: your partner for OEM parts for Clutches and SHAFT COUPLING compatibility

MOPA is an experienced and reliable partner for OEM spare parts for clutches across marine and stationary power applications. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines—covering friction packs, pressure plates, hubs, release systems, and complementary items matched to SHAFT COUPLING interfaces. Customers value rapid availability from a proven supply network, meticulous part identification and cross-referencing, and documentation that supports compliance and traceability. From urgent vessel turnarounds to planned overhauls, MOPA helps reduce lead times and technical risk so that your equipment returns to service quickly and performs as specified.

Engineering alignment for marine engine and diesel engine drivetrains

Our technical support team assists in selecting clutch configurations and OEM parts that align with your SHAFT COUPLING type, gearbox ratio, and duty cycle—towing, DP operations, dredging, auxiliary generation, or peak-shaving. By matching friction materials, actuation pressures, and thermal capacity to real operating profiles, we help ensure smoother engagement, less vibration, and longer service life across the entire drive line.

Conclusion: reliable Clutches paired with the right OEM spare parts

Clutches are indispensable for safe, efficient power transmission, working hand in hand with the SHAFT COUPLING to protect equipment and maintain performance. Choosing OEM spare parts suitable for clutches secures consistent quality, predictable service life, and cost-effective operation. MOPA supplies the speed and technical certainty needed to keep diesel and marine engine systems running at their best.