COMPENSATOR solutions for Compensators and manifolds in marine and diesel engines

Compensators and manifolds are core components in every combustion engine system, especially in demanding marine engine and diesel engine applications. Manifolds collect and channel gases between cylinders and turbochargers or intake systems, while the COMPENSATOR (flexible expansion joint/bellows) decouples thermal growth and vibration between the engine and attached piping. Together, they form the backbone of a stable gas path that protects equipment, optimizes turbocharger response, and maintains safe operating conditions.

In medium- and high-speed engines on ships, power plants, and heavy equipment, these parts operate under high temperatures, pulsating pressures, and continuous thermal cycling. Properly engineered manifolds maintain evenly distributed flow and low backpressure, and a correctly sized COMPENSATOR absorbs axial, lateral, and angular movement so that pipes, flanges, and turbochargers remain within stress limits. The result is efficient performance, compliance with safety standards, and long component life.

COMPENSATOR technical function with manifolds in a marine engine or diesel engine

On the exhaust side, the manifold collects cylinder pulses and directs them to the turbocharger while managing temperature and pulse timing. Marine manifolds are frequently water-jacketed to keep surface temperatures within safe limits in the engine room. On the intake side, the manifold distributes air evenly to all cylinders to stabilize combustion. Between these rigid parts and the connected pipework sits the COMPENSATOR, a flexible element that compensates for thermal expansion, hull deflection, machinery vibration, and installation tolerances.

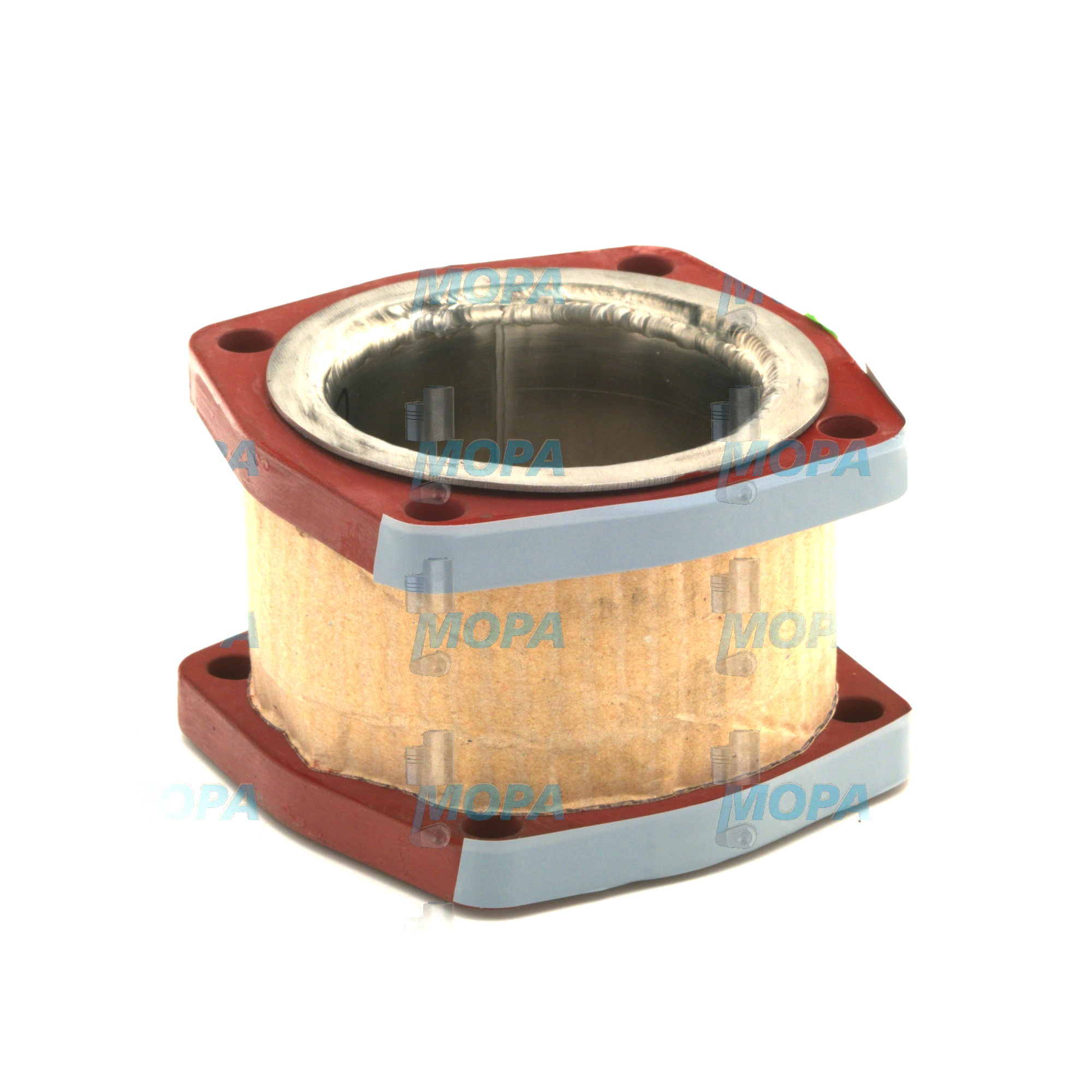

By isolating movement, the COMPENSATOR limits mechanical loads on manifold studs, turbocharger casings, and downstream silencers or SCR units. Inner sleeves (liners) can be used to smooth flow and protect the bellows from direct gas impingement, while tie rods or limit rods control travel. The correct COMPENSATOR for a marine engine or diesel engine is specified for temperature, pressure, movement range, and media, and in OEM parts form it matches the maker’s geometry and ply-count to maintain low leakage and stable dynamic behavior.

COMPENSATOR design features and materials

Typical materials include high-silicon molybdenum cast iron or austenitic ductile iron for exhaust manifolds, and stainless steels (e.g., 321 or 316L) or nickel-based alloys for bellows. Multi-ply bellows construction improves fatigue life under pulsating load. With proper liners and collars, the assembly reduces turbulence and erosion, helping the turbocharger maintain efficiency. Correct flange patterns and gasket surfaces ensure consistent sealing, decreasing the risk of soot tracks or hot gas leaks.

- · Absorbs axial, lateral, and angular movement

- · Reduces thermal stress on manifolds, turbochargers, and pipes

- · Maintains low exhaust backpressure for performance

- · Dampens vibration and pulsation to protect equipment

- · Enables tight sealing and leak control

- · Supports compliance with engine-room temperature limits

- · Materials and liners tailored to temperature and media

COMPENSATOR importance for engine operation and service life

Manifolds and the COMPENSATOR directly influence engine reliability, fuel economy, and emissions. Excessive exhaust backpressure (often limited to tens of millibar by engine makers) increases pumping losses and fuel consumption, while leaks raise engine-room temperatures and create safety risks. Without an effective COMPENSATOR, thermal growth from load changes can bend or crack rigid components, misalign turbocharger casings, and loosen flange joints. In gas engines, any imbalance can destabilize combustion; in diesel engines, uneven flow undermines turbocharger match and increases smoke under transient load.

Typical failure modes include bellows fatigue cracks, corrugation collapse due to overextension, gasket blow-by, manifold warping, and corrosion at water-jacket interfaces. Left unaddressed, these issues escalate to turbocharger damage, unplanned shutdowns, and non-compliance with class and safety rules. Regular inspection for soot traces, hot spots, and flange discoloration, combined with timely replacement of the COMPENSATOR and worn manifolds, preserves engine uptime and extends overhaul intervals.

OEM spare parts for COMPENSATOR and manifolds: performance, reliability, budget, service life

Choosing OEM spare parts suitable for Compensators and manifolds safeguards the engine’s designed performance. Precise geometry and flow characteristics protect turbocharger efficiency and keep backpressure within specification. Matched metallurgy and heat treatment resist high-cycle fatigue and thermal shock, especially in marine engine duty with frequent load changes.

With OEM spare parts, decision-makers gain predictable installation time and fit, minimizing downtime during port calls or planned outages. Leak-tested bellows, correct ply-count, and validated movement capability reduce the risk of premature failure. Traceable production and consistent quality management contribute to longer service intervals and lower total cost of ownership by avoiding repeat interventions and collateral damage to adjacent components.

Additional advantages include compatibility with existing brackets, supports, and heat shielding, as well as conformity to specified flange loads and vibration criteria. For fleets, standardized OEM spare parts across similar engine variants streamline inventory and simplify maintenance planning.

MOPA as a partner for COMPENSATOR OEM parts and manifolds

MOPA is an experienced and reliable partner for OEM spare parts in the category Compensators and manifolds. We supply COMPENSATOR OEM parts and manifold solutions for diesel and gas engines with a focus on speed, quality, and security in international trade. Our team identifies the correct configuration by engine type, serial number, and application profile to ensure movement capacity, materials, and liner options match the duty.

COMPENSATOR sourcing for marine engine fleets with MOPA

MOPA supports urgent deliveries, consolidated kitting for overhauls, and secure logistics to reduce laytime risk. Every step—quotation, documentation, and packing—is optimized for dependable lead times and careful handling. Technical support helps purchasers and superintendents select the right COMPENSATOR and manifold assemblies, gaskets, and fastening sets for a complete, installation-ready package.

Conclusion: COMPENSATOR and manifolds in engine systems

Compensators and manifolds are critical to gas-path integrity, turbocharger efficiency, and safe operation in marine engine and diesel engine installations. Selecting OEM spare parts suitable for this category delivers the precision, durability, and consistency needed to protect performance and extend engine service life.

With MOPA, purchasers and operators gain a trusted source for COMPENSATOR OEM parts and manifolds—fast, high-quality, and secure—so engines run efficiently and downtime stays under control.