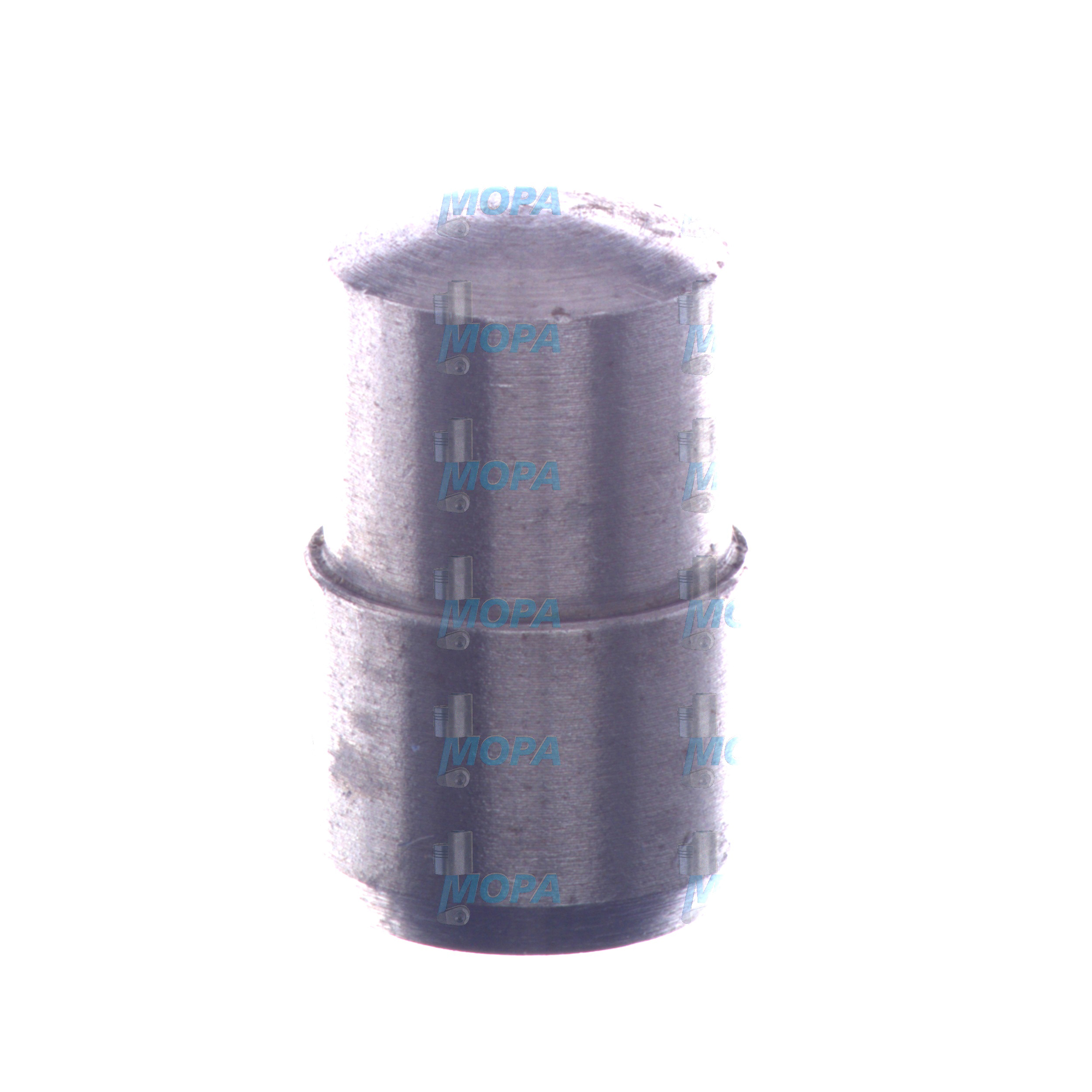

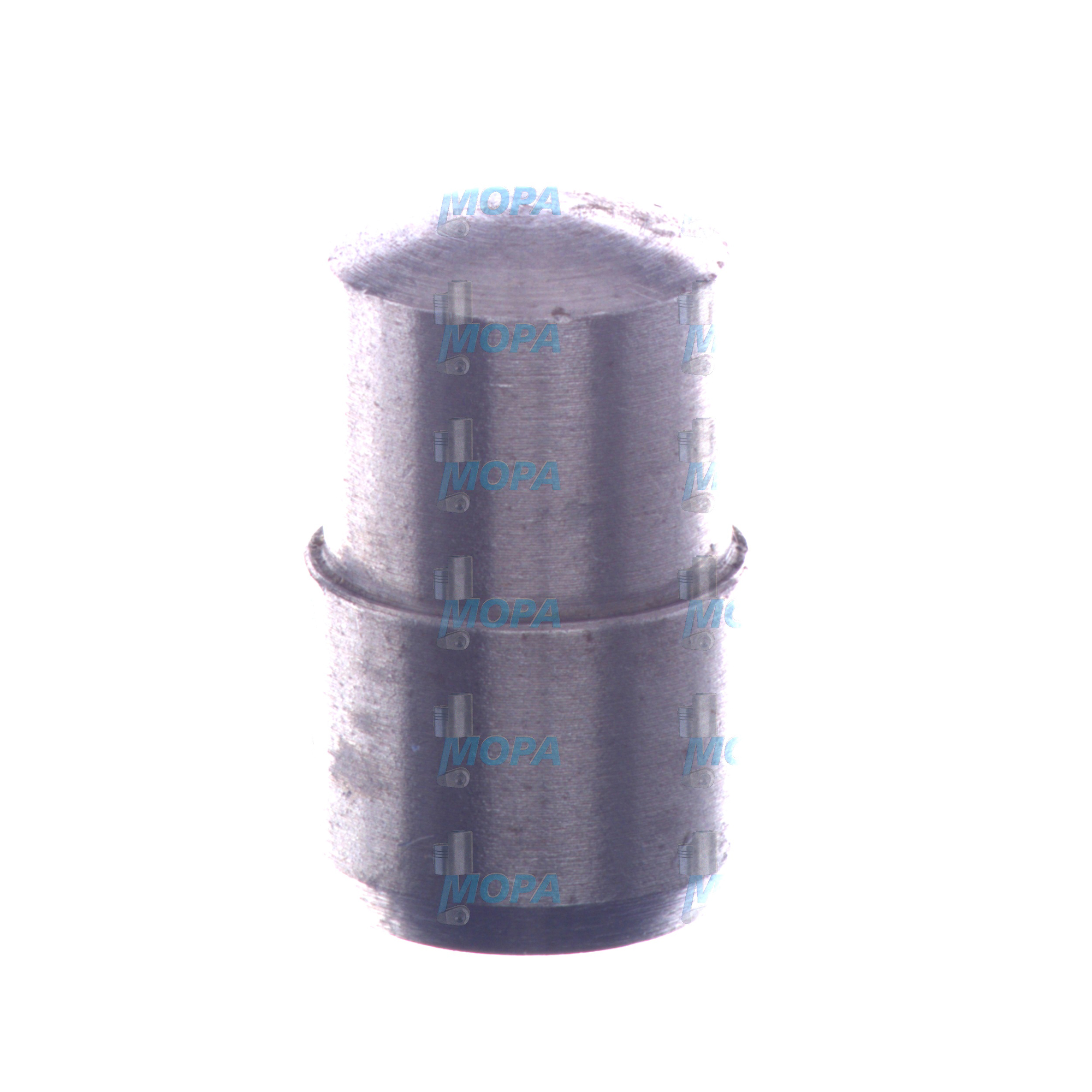

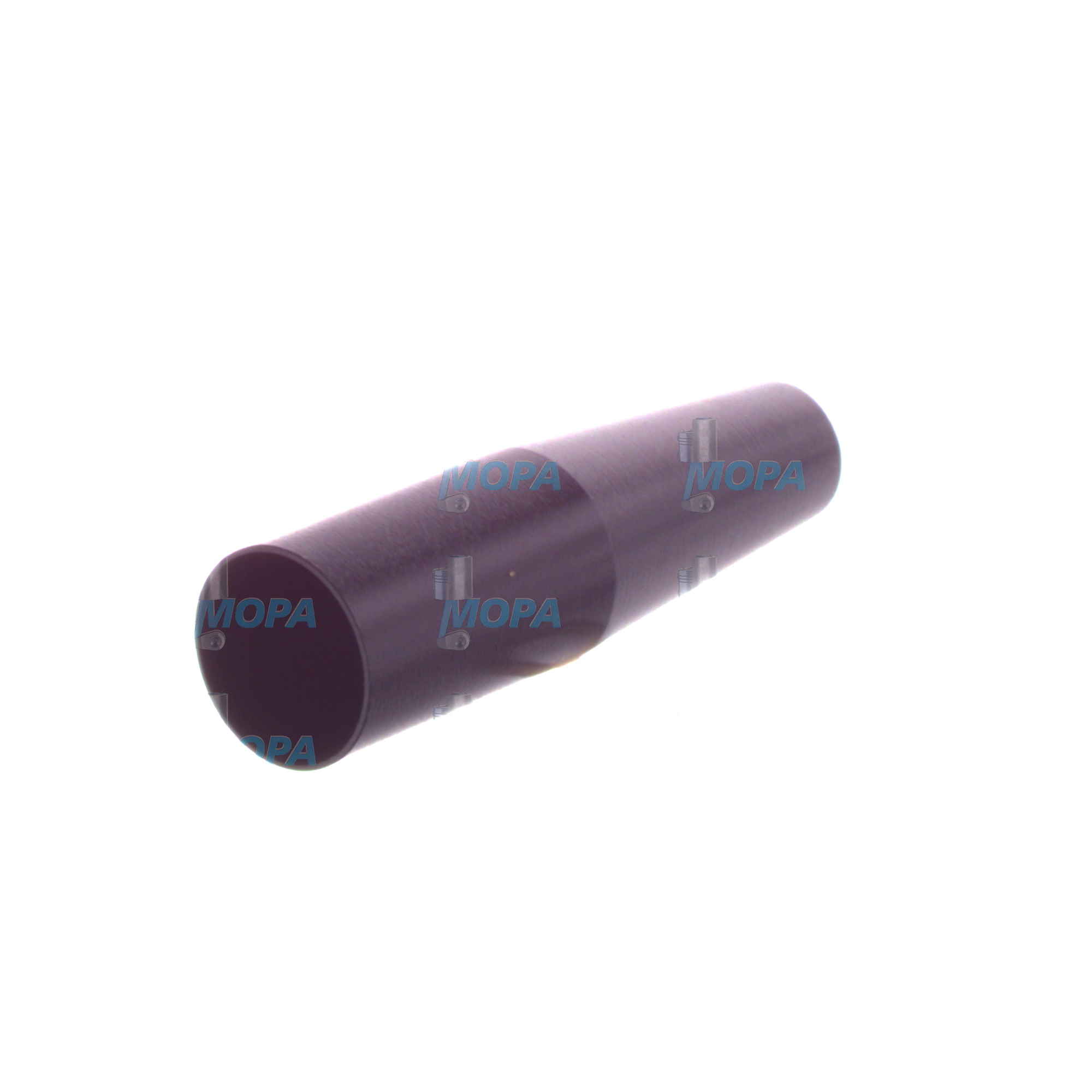

ASSEMBLY PIN connecting elements for marine and diesel engines

Connecting elements are the backbone of every engine assembly. This article category includes critical fasteners and locators such as bolts, studs, nuts, washers, dowels, and the ASSEMBLY PIN that ensures precise positioning during build and service. In both marine and diesel engines, these components create secure joints, maintain alignment under load, and support reliable sealing and power transmission. Without robust connecting elements, even the most advanced engine architecture cannot deliver consistent performance, efficiency, or safety.

In practice, connecting elements bridge the gap between design intent and real-world operation. They translate torque into clamping force, maintain joint integrity through thermal cycles, and prevent micro-movements that cause wear. The ASSEMBLY PIN serves a special role as a guide and locating element that ensures mating parts align within microns, providing the foundation for accurate timing, ideal bearing geometry, and leak-free interfaces. For shipowners and technical buyers, choosing the right set of connecting elements—supported by high-quality ASSEMBLY PIN OEM parts—is a direct investment in uptime and lifecycle cost control.

Technical function of connecting elements and ASSEMBLY PIN in engine systems

Connecting elements perform three fundamental tasks in engines: load transfer, precision alignment, and joint retention. Cylinder head bolts convert tightening torque into axial preload to seal combustion pressures. Main bearing cap bolts and conrod bolts maintain bearing crush and alignment for stable oil films. Studs and nuts reduce thread wear in the parent material and provide repeatable preload during service. Washers distribute load and protect surfaces. Dowel pins and the ASSEMBLY PIN define exact component positions so that rotating and reciprocating groups run true.

The ASSEMBLY PIN marine engine application is a good example. During block-to-head assembly or timing case installation, the pin ensures coaxiality and planarity of critical bores and faces. In a diesel engine, it locates bearing saddles, gear housings, and camshaft carriers to eliminate misalignment that would otherwise increase friction, noise, and wear. Accurate location enables even gasket compression, proper gear meshing, and optimized injector spray targeting—factors that directly influence power density, fuel efficiency, and emissions. When sourced as ASSEMBLY PIN OEM parts, the dimensional tolerances, surface finish, and heat treatment are matched to the engine maker’s specifications, delivering predictable fit (e.g., H7/m6 for dowel-type fits) and repeatable assembly outcomes.

Materials and coatings are engineered for harsh conditions. Typical connecting elements use alloy steels with controlled cleanliness and heat treatment for high tensile strength and fatigue resistance. Surface treatments such as phosphate, zinc-flake, or MoS2-based lubricants stabilize the coefficient of friction for consistent preload. For ASSEMBLY PIN components, precision-ground diameters, corner radii, and lead-in chamfers minimize galling and facilitate guided assembly without damaging mating bores.

- · High tensile and fatigue strength for cyclic engine loads.

- · Precision alignment via dowels and ASSEMBLY PIN locators.

- · Stable preload through controlled friction and surface finish.

- · Heat- and corrosion-resistant materials and coatings.

- · Dimensional accuracy for repeatable fit and serviceability.

- · Vibration resistance to prevent loosening and fretting.

- · Traceability and documentation for compliance and audits.

Why connecting elements are critical for reliability and service life

Reliability hinges on joint integrity and alignment. If connecting elements lose preload or if an ASSEMBLY PIN seat wears, the consequences cascade quickly: shifting components compromise gasket compression, leading to oil, coolant, or charge-air leaks; misaligned gears increase tooth stress and vibration; and eccentric bearing loads accelerate fatigue. In high-output diesel engines, even minor joint relaxation can elevate operating temperatures and fuel consumption.

Service issues often start with subtle deviations—stretched bolts operating beyond the elastic range, fretting at locating interfaces, or corrosion undermining thread friction. Regular inspection should include torque checks, angle monitoring during tightening, elongation measurement for critical bolts, and bore gauging at ASSEMBLY PIN locations. Replacement is advised when stretch exceeds specification, when thread crest damage or galling is visible, or when interference fit is no longer within tolerance. Proper lubrication and clean mating surfaces are essential to avoid scatter in preload that would otherwise produce uneven loading across the joint.

Failure modes mitigated by quality ASSEMBLY PIN and connecting elements

With premium connecting elements and an accurately machined ASSEMBLY PIN diesel engine fit, operators reduce risks such as fatigue cracking at thread roots, fretting corrosion at locators, hydrogen embrittlement from improper plating, and thermal relaxation in overloaded bolts. Correctly designed joints preserve sealing lines, maintain bearing geometry, and prevent gear whine—extending maintenance intervals and protecting major components like crankshafts and camshafts.

Advantages of OEM spare parts suitable for connecting elements and ASSEMBLY PIN

Choosing OEM spare parts suitable for connecting elements is a practical path to stable performance and lower total cost of ownership. These components are manufactured to the specified metallurgy, hardness profiles, and dimensional tolerances that deliver consistent preload and precise location. The result is fewer assembly variables, predictable torque-to-angle outcomes, and minimized risk of joint relaxation under thermal and dynamic loads. For an ASSEMBLY PIN OEM parts package, you can expect repeatable interference fits, correct edge chamfers for lead-in protection, and surface finishes that reduce galling—small details that have a big effect on uptime.

From a commercial perspective, the benefits are tangible: fewer unplanned stops due to leaking joints or misaligned housings, quicker overhauls because parts fit first time, and better fuel economy from maintained mechanical efficiency. OEM spare parts suitable for connecting elements also support documentation and traceability requirements demanded by classification societies and fleet audits, helping technical managers demonstrate control over critical components.

MOPA: fast, high-quality, and secure supply of OEM parts for diesel and gas engines

MOPA is an experienced and reliable partner for OEM spare parts connecting elements, including the ASSEMBLY PIN for marine engine and diesel engine applications. Customers value our speed in sourcing and delivery, our quality-driven selection of components, and our secure, transparent trade processes. We support fleet operators, shipyards, and power-plant owners with prompt quotations, optimized logistics, and careful packaging that protects precision surfaces and threads.

Whether you need a complete set of connecting elements for a major overhaul or specific ASSEMBLY PIN OEM parts for an alignment-critical job, MOPA provides technical documentation, material certificates on request, and clear part identification to streamline your maintenance. Our portfolio covers diesel and gas engines from leading manufacturers, enabling cohesive procurement and reduced downtime across mixed fleets.

Conclusion

Connecting elements—bolts, studs, washers, dowels, and the ASSEMBLY PIN—are fundamental to accurate assembly, durable sealing, and smooth, efficient engine operation. Selecting OEM spare parts suitable for connecting elements ensures the precision, consistency, and durability that protect performance and budget over the entire lifecycle.

MOPA combines expertise, speed, and secure processes to deliver the right ASSEMBLY PIN and related connecting elements for marine and diesel engines, keeping your equipment aligned, sealed, and running reliably.