BUSH Connecting elements for reliable engine assemblies

Connecting elements are the mechanical links that clamp, align, and isolate critical interfaces throughout an engine. This article category covers bolts, studs, nuts, washers, pins, sleeves, and precision bushings (BUSH) that join housings, secure rotating equipment, and maintain concentricity between moving parts. In both propulsion systems and auxiliary sets, these components keep loads under control, preserve sealing surfaces, and support the geometry that governs efficiency and durability. For purchasers and technical decision-makers, selecting the right connecting elements is a direct lever on uptime, lifecycle cost, and safety—especially in demanding marine engine and diesel engine environments.

Technical function: BUSH connecting elements in diesel engine and marine engine applications

Within a diesel engine, connecting elements deliver clamping force and stiffness at every critical joint—cylinder heads to blocks, main bearing caps to crankcases, exhaust manifolds to heads, turbocharger interfaces, gear housings, and accessory brackets. The objective is consistent preload: enough to resist combustion pressure and vibration without overstressing the fastener or the thread. Torque-and-angle methods, matched to the fastener’s strength and lubrication condition, help achieve predictable stretch and joint integrity over thermal cycles.

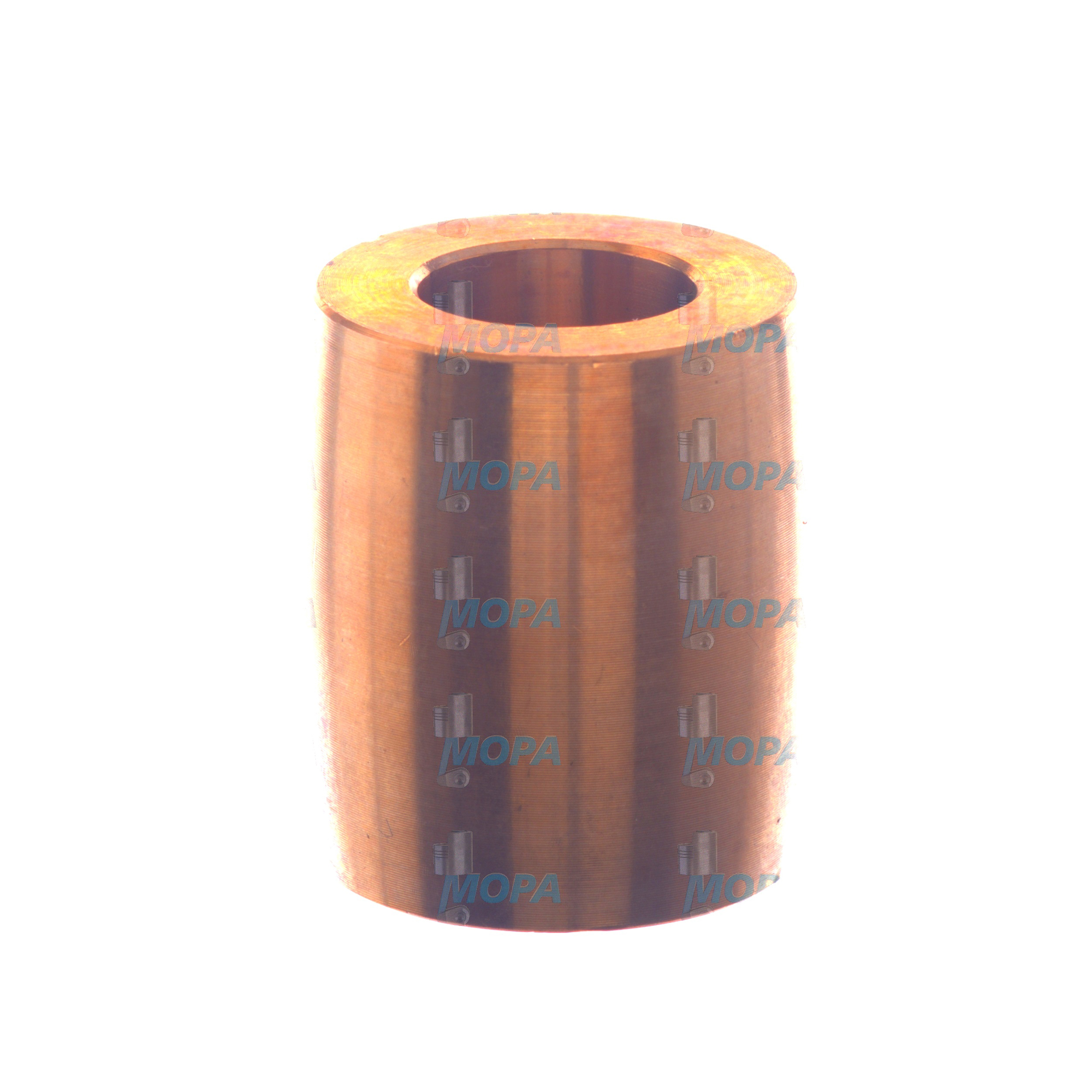

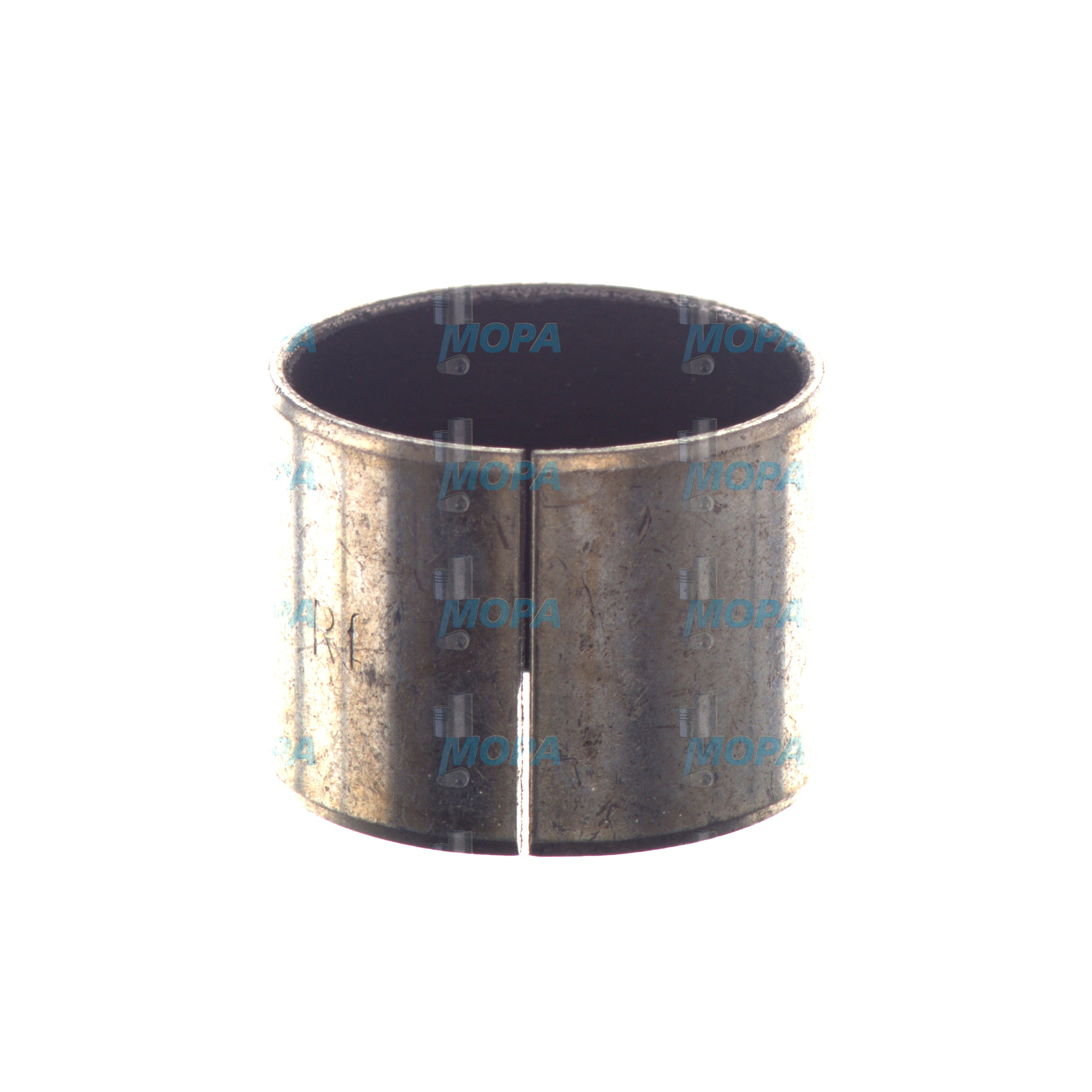

Bushings (BUSH) act as sacrificial, precisely sized sleeves that guide shafts, rocker arms, gears, and pins. In a BUSH marine engine or BUSH diesel engine context, they control clearance, reduce friction, and isolate dissimilar metals. By distributing loads over a larger surface and providing an optimized bearing layer—often bronze, steel-backed composite, or polymer-lined—the bushing prevents galling and fretting, dampens vibration, and keeps alignment stable under shock and tilt. Properly selected BUSH OEM parts maintain the kinematics intended by the engine designer, directly influencing valve timing accuracy, gear mesh quality, and pump efficiency.

Surface treatments on fasteners—phosphate, zinc-nickel, or specialized anti-corrosion coatings—support repeatable tightening and long-term corrosion resistance, particularly in salty, humid marine atmospheres. Locking features (prevailing torque nuts, thread-locking patches, safety wire provisions) protect against loosening. For hot zones such as exhausts, high-temperature alloys and controlled microstructures maintain strength and creep resistance, guarding against relaxation and loss of preload.

- · High-strength bolts and studs deliver stable preload across thermal cycles.

- · Precision BUSH sleeves maintain alignment and protect shafts and housings.

- · Engineered coatings improve torque consistency and corrosion resistance.

- · Locking features resist vibration-induced loosening.

- · Material pairs in bushings reduce friction and prevent galling.

- · Tight tolerances keep clearances within design limits, sustaining efficiency.

Importance for engine operation: why BUSH connecting elements matter

When connecting elements are in top condition, joints remain sealed, rotating parts stay concentric, and the engine operates within its designed vibration and noise envelope. If they wear or are poorly matched, the consequences escalate quickly. Loss of preload in a head joint can lead to combustion gas leakage, hot-spotting, and head-gasket failure. Relaxed manifold fasteners trigger exhaust leaks that harm turbocharger response and raise EGTs. Misfitted BUSH sleeves permit shaft or rocker arm misalignment, causing edge loading, accelerated bearing wear, and timing drift. In gear trains and pumps, excessive clearance invites noise, pitting, and energy losses.

Corrosion on fastener threads can skew torque-to-tension relationships, leaving joints under-clamped even at the correct torque value. Over time, this progresses to fretting, crack initiation at stress risers, and ultimately catastrophic joint failure. In marine engine applications with constant thermal cycling and vibration, the margin for error is especially small. Correctly specified BUSH diesel engine elements stabilize the system, reduce downtime, and preserve service intervals.

Advantages of OEM spare parts suitable for Connecting elements

Using OEM spare parts suitable for connecting elements ensures that material grades, heat treatment, and dimensional tolerances match the engine designer’s intent. This is vital for joints loaded near yield or for precision fits where micron-level variance affects performance. With OEM BUSH sleeves and fasteners, the fit between pin and bushing is consistent across batches, thread geometry is precise, and coating specifications deliver predictable friction coefficients for accurate tightening. The result is replicable assembly quality, fewer re-torque events, and stable clearances throughout the maintenance cycle.

From a budget standpoint, right-first-time assembly prevents rework and collateral damage caused by misaligned shafts, leaking joints, or vibratory loosening. Over the service life of a diesel or gas engine, the cumulative savings from reduced downtime, preserved efficiency, and longer component life outpace the cost of proper parts selection. For performance, OEM BUSH components hold clearances that maintain oil film stability, while correctly matched fasteners protect sealing performance and turbocharger efficiency—both critical to fuel consumption and emissions.

MOPA as your partner for OEM spare parts BUSH connecting elements

MOPA supplies OEM spare parts suitable for connecting elements across leading diesel and gas engine platforms. As a specialized partner, MOPA focuses on speed of delivery, consistent quality, and transactional security—key factors when vessels are on tight schedules or plants run base-load operations. Whether you need BUSH marine engine sleeves for rocker arms and gear trains, or high-strength fasteners for cylinder heads, manifolds, and turbocharger mounts, MOPA streamlines sourcing and ensures specification accuracy.

Speed, quality, and security in BUSH OEM parts for diesel and gas engines

Lean logistics, competent technical support, and traceable documentation help you maintain control over critical interfaces. With MOPA, purchasers and shipowners gain a dependable route to BUSH OEM parts that match drawing-level requirements for strength class, hardness, coating, and tolerance.

Conclusion: BUSH Connecting elements for lasting engine performance

Connecting elements—especially precision BUSH sleeves and correctly matched fasteners—are foundational to engine reliability, efficiency, and safety. By choosing OEM spare parts suitable for connecting elements, you protect preload, alignment, and sealing integrity, directly extending service life and safeguarding budgets. MOPA supports this with rapid, secure supply of BUSH diesel engine and marine engine components that keep critical joints performing as designed.