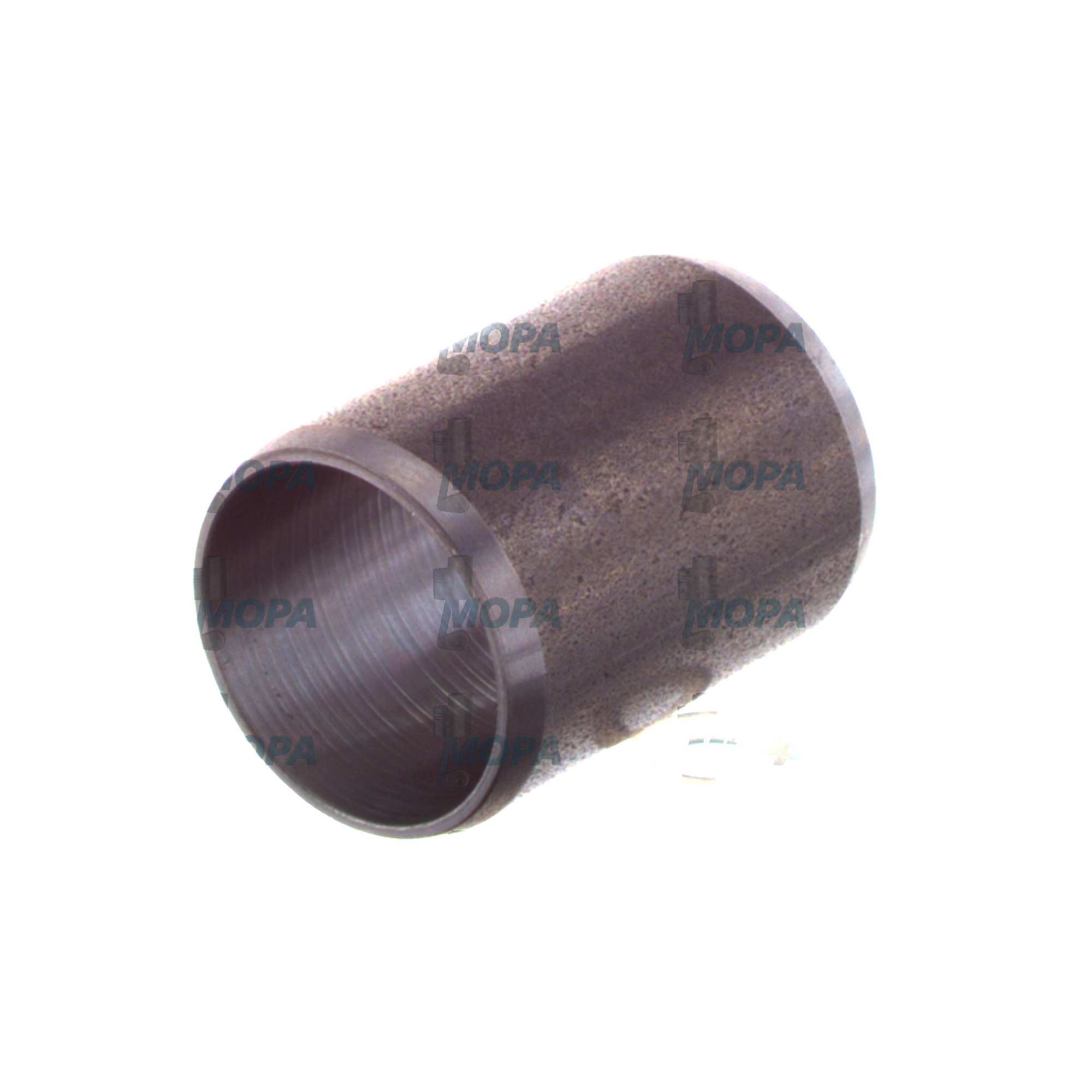

CENTERING BUSH connecting elements for high‑demand diesel and marine engines

Connecting elements are the precision components that join, align, and secure engine assemblies under heat, vibration, and cyclic loads. This category includes bolts, studs, nuts, washers, pins, and locating sleeves such as the CENTERING BUSH. In large diesel engine rooms as well as compact gas-engine installations, these parts maintain geometry between housings and rotating groups, enabling efficient combustion, low vibration, and long service life. Without correctly specified connecting elements, even the best-machined castings cannot hold their tolerances in operation. That is why purchasers and superintendents treat them as strategic components rather than consumables.

Technical function: Connecting elements and CENTERING BUSH in a diesel engine or marine engine

Within an engine, connecting elements fulfill two core tasks: positional location and clamping. Bolts and studs provide the clamping force; a CENTERING BUSH locates components with repeatable accuracy by defining the position of mating parts. On crankcases, cylinder heads, bedplates, gear housings, or flywheel casings, the CENTERING BUSH fixes concentricity and shear position so bolts are not overloaded sideways. This separation of duties—location by bush, preload by fastener—keeps joint behavior predictable over millions of cycles.

A typical CENTERING BUSH for marine engine assemblies uses controlled fits (for example H7/h6) to achieve close runout and alignment. The bush absorbs lateral shear, stabilizes gasket compression, and keeps bores, shafts, or gear trains coaxial, reducing friction and the risk of seal lip damage. In turbocharger brackets or pump drives on a diesel engine, a correctly dimensioned CENTERING BUSH ensures accessory alignment and reduces belt or gear wear. High-quality CENTERING BUSH OEM parts are usually manufactured from alloy steels such as 16MnCr5 or 42CrMo4 and case-hardened for wear resistance, with anti-corrosion finishes to withstand salt-laden atmospheres.

Because thermal gradients are inevitable, locating bushes are also designed with lead-in chamfers and surface finishes that enable controlled assembly and disassembly. Their geometry prevents fretting, minimizes micro-movement in the joint, and helps maintain sealing integrity. In short, the CENTERING BUSH transforms multi-part castings into one rigid, well-aligned structure, directly supporting stable power output and lower NVH.

- · Maintains concentricity between housings and shafts.

- · Carries shear loads so bolts focus on preload.

- · Reduces vibration, noise, and gear or bearing wear.

- · Preserves gasket compression and sealing lines.

- · Enables repeatable service assembly with precise fits.

- · Wear-resistant materials and controlled heat treatment.

- · Corrosion protection suitable for marine environments.

- · Dimensional consistency aligned with ISO/DIN fit classes.

Importance for engine operation and service life with CENTERING BUSH

Reliable alignment is fundamental to engine efficiency. When connecting elements and their CENTERING BUSH lose dimensional accuracy, the consequences cascade: shafts run out, bearings carry uneven loads, and gears mesh incorrectly. That leads to hot-running bearings, scuffed seals, abnormal gear patterns, and elevated vibration. Even a small loss of concentricity can degrade combustion stability in a high-output diesel engine by disturbing cam timing or fuel-pump phasing.

Common failure modes include fretting corrosion on mating faces, ovalized bushing bores, and bolt fatigue due to unintended shear. In marine engine blocks, misalignment at the bedplate joint can cause uneven main-bearing wear and oil film collapse. On auxiliary gearboxes, poor location can accelerate tooth pitting and raise noise levels. Preventive replacement of worn connecting elements and CENTERING BUSH components protects uptime, keeps lubrication temperatures in range, and maintains compliance with class and emission targets.

Advantages of OEM spare parts suitable for Connecting elements and CENTERING BUSH

Choosing OEM spare parts for this category delivers measurable technical and commercial benefits. Tight tolerance control guarantees the intended fit—press, transition, or slip—so joints behave as designed. Certified metallurgy and heat treatment secure surface hardness for wear resistance while retaining a tough core to resist impact. Chamfer geometry, case depth, and surface roughness are consistent, safeguarding sealing lines and minimizing fretting. For purchasers, this translates into predictable assembly, fewer reworks, and shorter outage windows.

From a budget perspective, correct fit-up reduces collateral damage to expensive housings and bearing seats, cutting total life-cycle cost. Performance-wise, a matched CENTERING BUSH in an OEM parts set keeps critical driveline axes aligned, improving efficiency and lowering vibration. Reliability improves because bolts retain preload, gaskets stay evenly compressed, and rotating components run within designed tolerances. Across diesel and gas engines, the result is longer service intervals and stable performance metrics.

CENTERING BUSH OEM parts for marine engine and diesel engine reliability

Procurement of CENTERING BUSH components as OEM parts ensures interchangeability across engine frames and build standards, supports traceability, and eases documentation for audits and class requirements. It also simplifies logistics: one precise specification, verified dimensions, and a part that fits right the first time.

MOPA: fast, secure supply of OEM parts CENTERING BUSH and connecting elements

MOPA is an experienced partner for OEM spare parts in the connecting elements category, including every CENTERING BUSH required for diesel and gas engines. Customers value our speed of delivery, proven quality, and secure transactions. We provide curated stock for critical engines, robust packaging for maritime shipments, and technical support to identify the correct locating bush, stud kit, or fastener set by drawing, engine model, or cross reference.

Whether you need a CENTERING BUSH for a marine engine bedplate, a gearbox housing locator for a diesel engine, or a complete set of connecting elements for an overhaul, MOPA streamlines the process from inquiry to installation—on time and with full part traceability.

Conclusion: CENTERING BUSH and connecting elements safeguard engine performance

Connecting elements—especially the CENTERING BUSH—are small parts with an outsized impact on alignment, efficiency, and service life. Specifying OEM spare parts suitable for these components protects performance and budget by ensuring precise fits, stable operation, and dependable uptime in diesel and marine engines.