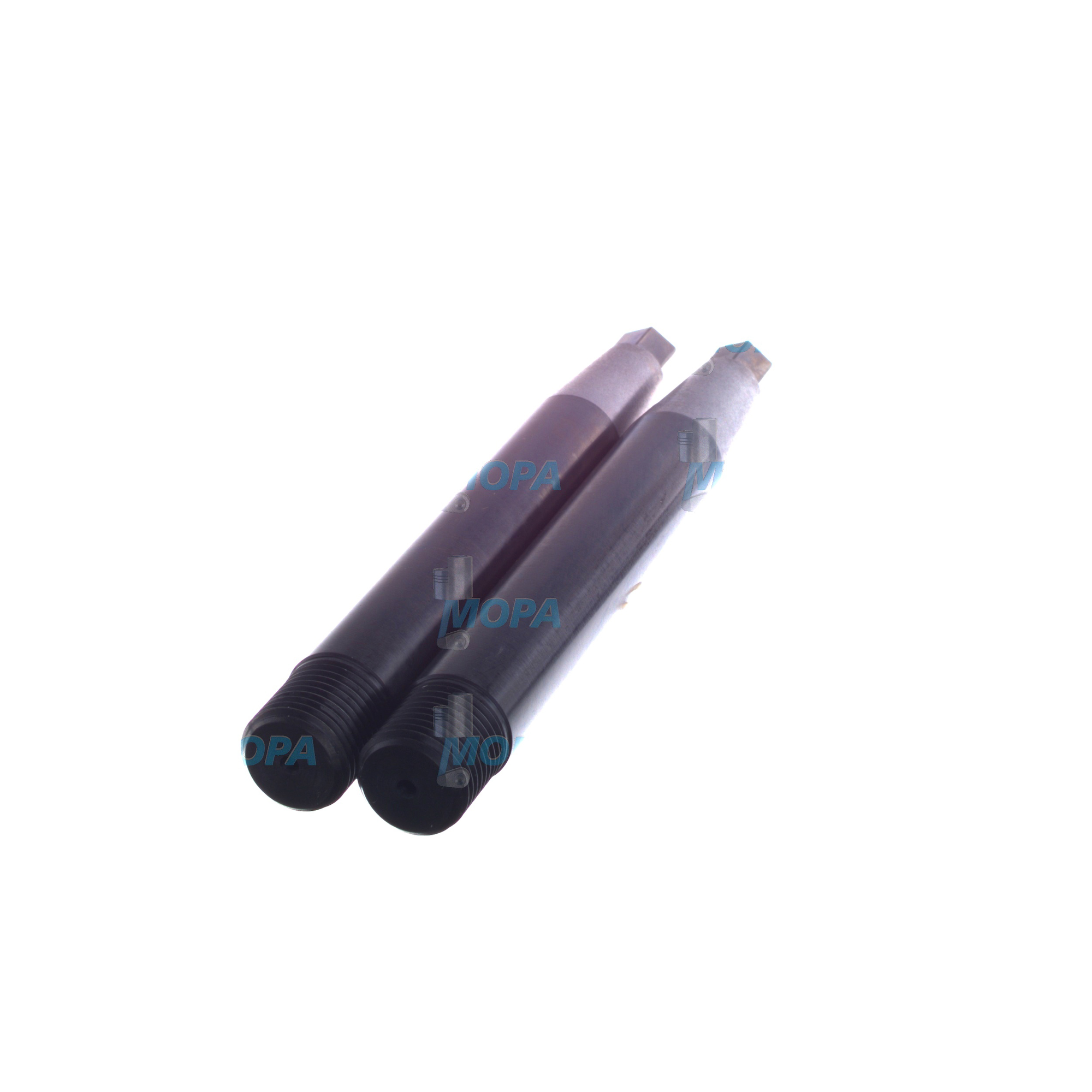

CENTERING PIN connecting elements for marine and diesel engines

Connecting elements are the precision fasteners and locating components that assemble, align, and secure the major groups inside an engine. They include items such as bolts, studs, nuts, washers, clamps, dowels, and the highly critical CENTERING PIN. Without these components, cylinder blocks, heads, bearing caps, timing cases, turbocharger housings, and auxiliary systems cannot form a stable and efficient unit. In marine and diesel engines that operate under high loads and long duty cycles, connecting elements determine how reliably power is transmitted, how well sealing lines remain tight, and how accurately rotating and reciprocating parts stay aligned.

In practice, connecting elements transform design intent into mechanical reality: they locate components with micrometer accuracy, create repeatable clamping forces, resist vibration, and preserve alignment over thousands of hours. Their performance affects everything from combustion quality and emissions to bearing life and shaft alignment.

Technical function of CENTERING PIN and connecting elements in a diesel engine

Connecting elements serve two primary functions: positioning and clamping. A CENTERING PIN provides precise positioning by defining the relative location between parts—commonly between cylinder block and head, gear housing and block, or flywheel housing and block. In a marine engine, a CENTERING PIN ensures that dowel-located joints are reassembled to the exact datum, safeguarding gear mesh, shaft concentricity, and gasket seating. Bolts and studs then apply the clamping force that maintains sealing and rigidity through thermal cycles and dynamic loads.

How it works in detail: during assembly, the CENTERING PIN enters a matched hole pair with a defined fit (often h6/H7 or similar), removing lateral play so that shear loads are carried by the pin rather than the bolts. This separation of duties prevents slippage that could otherwise frett mating surfaces or loosen fasteners. Studs and bolts—typically in high-strength property classes—provide a calibrated preload via torque-angle tightening, maintaining surface pressure even as materials expand or relax. Washers and flanged nuts help control friction scatter, while coatings such as phosphate or zinc-nickel improve corrosion resistance and torque consistency.

On high-output diesel engines, the combined action of CENTERING PIN and clamping elements preserves the accuracy of bearing bores, the squareness of cylinder liners, and the alignment of cam/carrier assemblies. In turbocharger and exhaust interfaces, correct alignment reduces thermal stress and prevents leakage. For service teams, CENTERING PIN OEM parts enable repeatable assembly geometry after overhauls, which is essential to restore baseline performance.

- · Precise alignment under thermal and dynamic loads.

- · Repeatable positioning for heads, housings, and carriers.

- · Controlled preload to maintain sealing and stiffness.

- · Reduced fretting, micro-movement, and bolt shear.

- · Corrosion-resistant materials and coatings for marine duty.

- · Tight tolerances for reliable fit (e.g., h6/H7 interfaces).

- · Stable torque-angle behavior and traceable quality.

Importance for engine operation: CENTERING PIN connecting elements and reliability

Reliability and service life depend on how well components remain aligned and clamped over time. If a CENTERING PIN is worn, undersized, or incorrectly fitted, small positional errors can propagate into big problems: skewed gear mesh leading to noise and tooth wear, bearing misalignment causing elevated temperatures, or gasket line displacement that triggers oil, fuel, or coolant leaks. Similarly, if bolts or studs lose preload due to fatigue, corrosion, or embedment, vibration increases and sealing margins drop.

Typical failure modes linked to compromised connecting elements include fretting corrosion at joint interfaces, ovalized bores in main bearing saddles, head-gasket blow-by, cracked manifolds from thermal stress, and accelerated wear of timing components. In a marine engine, where uptime is mission-critical, such issues translate directly into unplanned stops, higher fuel burn, and costly dockside repairs. Using the correct CENTERING PIN in a diesel engine preserves datum accuracy and protects adjacent systems from cascading damage.

Advantages of OEM spare parts suitable for connecting elements

OEM spare parts suitable for connecting elements are engineered to the same dimensional fits, material grades, and heat-treatment windows that the engine design expects. That means consistent pin hardness and surface finish for low insertion wear, correct interference or clearance for location holes, and predictable fastener elasticity for accurate preload. The result is stable alignment, fewer re-torque events, and longer intervals between overhauls.

For purchasing and technical teams, the value is measurable across performance, reliability, budget, and service life. Precision CENTERING PIN OEM parts limit rework time during overhauls, reduce alignment checks, and help maintain emissions and fuel efficiency by preserving combustion geometry. Traceable materials and controlled coatings deliver corrosion resistance in saline environments, extending maintenance intervals and protecting budgets from premature component replacement.

MOPA as your partner for OEM parts: CENTERING PIN and connecting elements

MOPA supplies OEM spare parts suitable for connecting elements—CENTERING PIN, dowel, bolt, stud, nut, and washer sets—across leading diesel and gas engine platforms. As an experienced and reliable partner, MOPA focuses on speed, quality, and security in the trade of OEM parts for diesel and gas engines. Customers benefit from short lead times, consistent specifications, and dependable logistics that keep overhaul schedules on track.

Whether you need a CENTERING PIN for a marine engine top-end rebuild or a complete set of critical fasteners for a major, MOPA provides technical clarity on fits, coatings, and tightening strategies, helping your teams assemble once and assemble right. With application-savvy support, you get the exact connecting elements required to preserve alignment and preload in demanding operating profiles.

Conclusion on CENTERING PIN connecting elements

Connecting elements are the hidden enablers of engine performance, and the CENTERING PIN is central to precise alignment in both marine and diesel engines. Selecting OEM spare parts suitable for connecting elements safeguards alignment, preload, and corrosion resistance, directly improving reliability and lifecycle cost. Partnering with MOPA ensures fast, secure access to the right components so your engines operate at their designed potential.