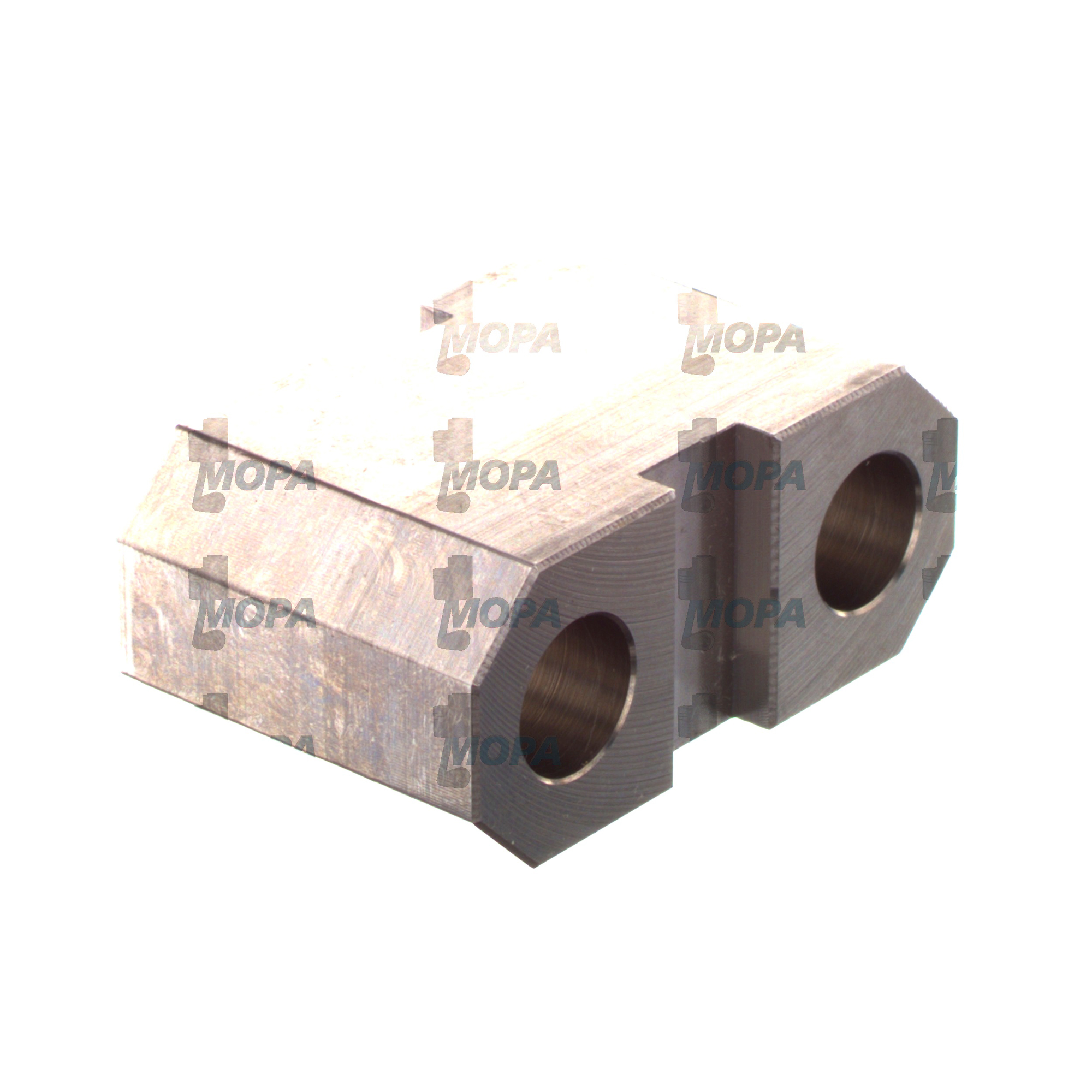

CONNECTING PIECE connecting elements for marine and diesel engines

Connecting elements are the precision links that join engine subsystems into a coherent, high‑performing whole. They include fittings, flanges, couplings, unions, adapters, clamps, elbows, tees, banjo bolts, and quick connectors—every component that mechanically or fluidically ties fuel, lube oil, coolant, charge air, and exhaust paths together. In large marine engine and industrial diesel engine installations, these parts provide leak‑tight flow, structural stability, vibration management, and accurate alignment. Without robust connecting elements, even a perfectly designed engine cannot achieve its rated output, efficiency, or safety level over time.

In day‑to‑day operation, connecting elements must handle pressure pulsations from fuel injection, temperature swings from cold starts to full load, and shipboard vibration. They must also resist corrosion from seawater atmosphere and process media such as MGO, HFO, lube oil, glycol, or gas. The right specification—dimension, material, coating, sealing concept, and pressure class—ensures that a CONNECTING PIECE for marine engine and diesel engine circuits performs reliably across maintenance cycles.

Technical function of CONNECTING PIECE connecting elements in engine systems

Within an engine, connecting elements perform three critical tasks: establishing sealed pathways, maintaining mechanical alignment, and accommodating dynamic loads. A compression fitting or union forms a leak‑tight joint between tube and component, preserving fuel pressure and preventing air ingress. A flange with the correct gasket material supports thermal expansion while keeping coolant circuits sealed. A flexible coupling or hose tail isolates vibration between the main engine and skid‑mounted auxiliaries. Each CONNECTING PIECE diesel engine assembly must match media compatibility, pressure/temperature ratings, and geometry to avoid flow restrictions, turbulence, and premature wear.

Sealing concepts range from metal‑to‑metal cones and double‑ferrule compression to O‑ring face seals. Materials typically include stainless steels (AISI 316/316L), carbon steels with protective coatings, copper‑nickel alloys for seawater exposure, or brass for low‑pressure instrumentation. Thread standards (metric, BSP, NPT), flange norms (EN, ISO), and torque classes must be consistent throughout the installation. Correct torque, surface finish, and cleanliness are essential—particularly on high‑pressure fuel pipes and lube oil manifolds—where a mis‑fitted CONNECTING PIECE OEM parts interface could lead to micro‑leaks or fatigue.

On marine engine applications, connecting elements also uphold class and safety expectations by delivering verifiable strength, traceable materials, and stable sealing under shock and vibration. In gas‑engine service, low‑leakage performance and ignition source control are central requirements; precision‑machined fittings with proven tightness reduce fugitive emissions and fire risk.

- · Leak‑tight sealing under pulsation and vibration.

- · Correct pressure and temperature ratings for each medium.

- · Corrosion‑resistant materials for marine environments.

- · Precision threads and sealing faces for repeatable assembly.

- · Alignment features that prevent stress and fatigue.

- · Compatibility with engine maker standards and dimensions.

- · Documented traceability and consistent quality levels.

- · Designed for serviceability and fast replacement.

Why connecting elements are vital for reliable engine operation

Reliable engines depend on stable fluid and air pathways. If connecting elements degrade, several issues emerge quickly: fuel leaks reduce injection pressure, causing poor combustion, higher SFOC, and power loss; coolant seepage leads to hotspots, scaling, and potential liner damage; lube oil leakage compromises bearing protection and accelerates wear; charge‑air leaks lower scavenging efficiency and raise exhaust temperatures. Beyond performance loss, any escaping fuel or gas increases safety risks and potential off‑hire events.

Typical failure modes include thread galling, ferrule over‑compression, gasket creep, O‑ring aging, corrosion pitting, and vibration‑induced fretting. Correct selection and timely renewal of connecting elements extend engine service life. Routine torque checks, cleanliness during assembly, and adherence to specified tightening sequences help prevent distortion and maintain seal integrity. When components are dimensionally accurate and media‑compatible, the whole system benefits from predictable maintenance intervals and minimized unplanned shutdowns.

Advantages of OEM spare parts suitable for connecting elements and CONNECTING PIECE

Fitting like‑for‑like is critical where tolerances are tight and safety margins are engineered into every joint. OEM spare parts suitable for connecting elements deliver repeatable fit, certified materials, and sealing geometry that matches the engine layout. Correct thread forms, cone angles, and gasket seat profiles minimize assembly time and reduce rework. Pressure classes, cleanliness levels, and hardness specifications are consistent, supporting long‑term performance in both diesel and gas engine environments.

Using OEM spare parts suitable for a CONNECTING PIECE marine engine installation supports:

• Performance: preserved flow coefficients and injection pressures maintain power and efficiency.

• Reliability: proven sealing concepts resist pulsation, thermal cycles, and vibration.

• Budget control: fewer leaks and re‑assemblies reduce labor and consumable costs over the lifecycle.

• Service life: material and coating specifications slow corrosion and wear, extending intervals between overhauls.

Documentation such as material certificates and batch traceability simplifies compliance with vessel stakeholders and safety audits. The result is a stable, predictable installation where each replacement part integrates seamlessly.

MOPA: fast, secure supply of OEM parts for CONNECTING PIECE applications

MOPA is an experienced partner for OEM spare parts suitable for connecting elements across diesel and gas engines. Purchasers and shipowners rely on our speed—short lead times, proactive availability checks, and agile global logistics—to keep assets operating. Our quality focus includes rigorous supplier qualification, incoming inspections, and full traceability, ensuring that each CONNECTING PIECE for diesel engine or marine engine service meets the specified standard.

Security in trade is embedded in our process: documented sourcing, clear cross‑references, and technical support that matches components to engine layouts and media. Whether you need high‑pressure fuel fittings, coolant flanges, lube oil unions, or gas‑tight compression joints, MOPA provides consistent OEM parts with dependable delivery and technical clarity.

Typical systems served with CONNECTING PIECE connecting elements

Fuel injection and return lines, lube oil distribution, jacket‑water and seawater cooling circuits, charge‑air manifolds, exhaust connections, crankcase breather lines, and instrumentation networks all depend on correctly specified connecting elements. Selecting the right component safeguards uptime and keeps engines within performance and emission targets.

Conclusion

Connecting elements are the discreet yet decisive components that keep fuel, oil, coolant, air, and exhaust moving safely through every engine. Specified and maintained correctly—using OEM spare parts suitable for a CONNECTING PIECE—they protect performance, extend service life, and stabilize operating costs. MOPA supports you with fast, high‑quality, and secure supply so your marine and diesel engines continue to run at their best.