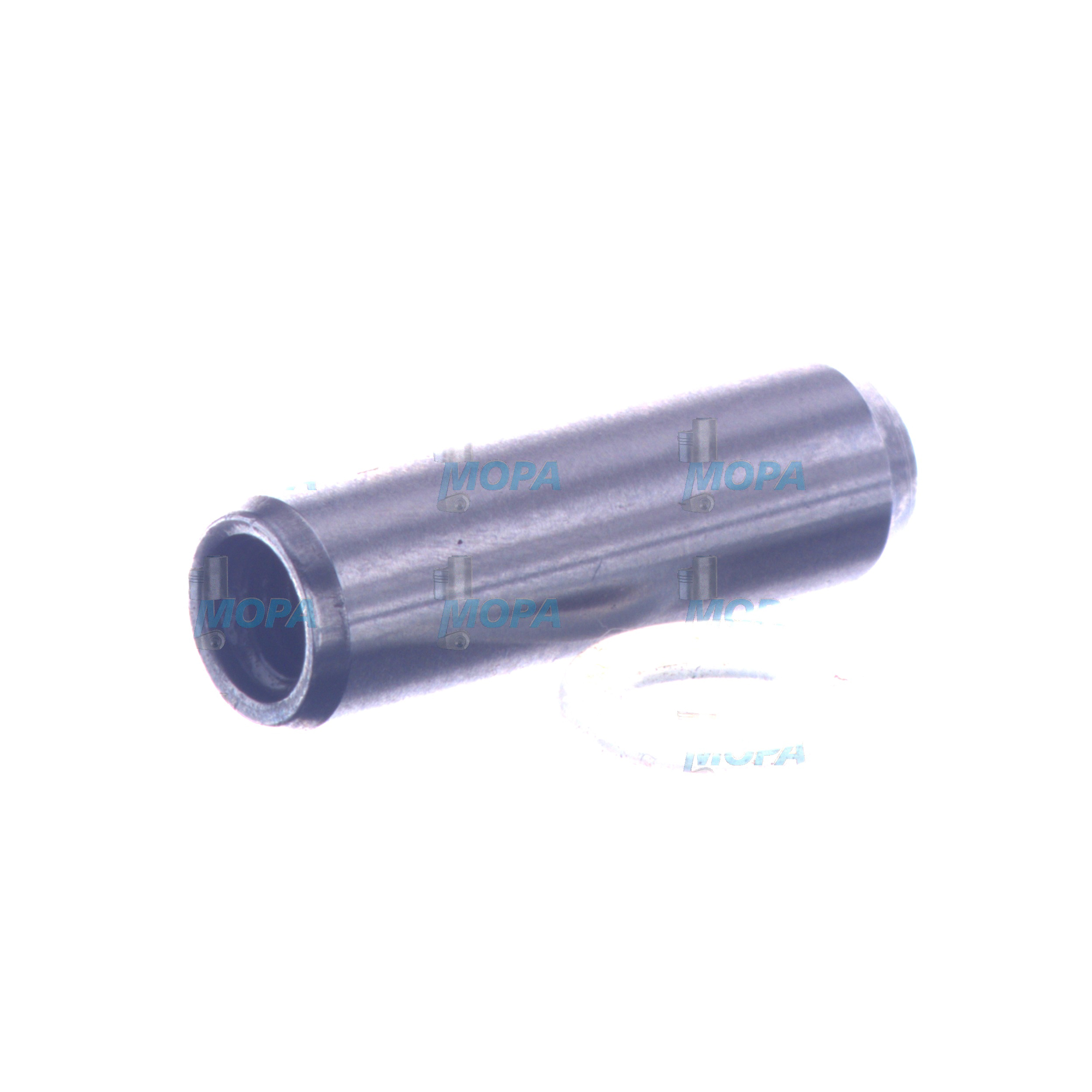

DOWEL PIN connecting elements for marine and industrial engines

Connecting elements are the unseen backbone of every engine assembly. This category includes precision parts such as bolts, studs, nuts, washers, keys, and especially the DOWEL PIN. Together they clamp, align, and secure housings, heads, bearing caps, gear covers, and auxiliaries so that a diesel or gas engine can deliver reliable power under sustained load. In heavy-duty marine engine applications and stationary power generation, correct selection and condition of connecting elements directly influence uptime, fuel efficiency, and safety.

Within this category, the DOWEL PIN plays a critical role: it precisely locates components relative to each other, ensuring geometry is maintained across start–stop cycles, thermal expansion, and vibration. When alignment is right, sealing lines remain stable, gear meshes run true, and rotating assemblies stay within design clearances—saving fuel, preventing leaks, and extending service intervals.

Technical function of connecting elements and DOWEL PIN in a diesel engine

Connecting elements provide two essential functions: they maintain clamping force and they preserve alignment. Bolts and studs generate the clamp load that resists combustion pressure and dynamic forces. The DOWEL PIN, by contrast, takes care of accurate positioning so bolts are not forced to work in shear. In a DOWEL PIN diesel engine application, pins locate the cylinder head to the block, main bearing caps to the crankcase, timing gear housings to the cam carrier, and fuel injection pumps to their drive—ensuring timing, gear backlash, and sealing are correct from the first start to the next overhaul.

A DOWEL PIN marine engine installation faces additional stresses: hull-borne vibration, long run hours, and thermal gradients. Precision-ground pins keep components from creeping under these conditions, protecting head gaskets and preventing fretting corrosion between mating faces. In practice, DOWEL PIN OEM parts are produced to tight tolerances (common fits include H7/h6 or H7/m6, depending on whether a slip- or press-fit is required in one component) and manufactured to standards such as ISO 8734 or DIN 6325. Materials range from hardened alloy steel for high-load zones to stainless variants for corrosion-prone environments. Chamfers and radii are optimized to avoid burrs during assembly, while surface finishes support consistent friction and long-term stability.

- · Precise alignment of mating components under thermal and dynamic load

- · Transfers shear forces away from bolts and studs, preserving clamp load

- · Protects sealing lines for head, cover, and manifold gaskets

- · Reduces vibration, noise, and gear mesh error

- · Heat-treated steels and corrosion-resistant options for marine duty

- · Tolerance-controlled fits (e.g., H7/h6 or H7/m6) for repeatable assembly

- · Conforms to recognized standards (e.g., ISO 8734, DIN 6325)

Importance for engine operation and service life

Reliable alignment is fundamental to engine longevity. If a connecting element such as a DOWEL PIN wears, deforms, or is missing, components can shift under load. The immediate effects include uneven gasket compression, localized leakage, and bolt preload loss. Over time, this leads to fretting on joint faces, groove formation around dowel bores, and distorted housings.

Consequences in daily operation can be serious: a misaligned cylinder head raises the risk of coolant or combustion gas leakage; a shifted bearing cap alters oil film distribution and accelerates journal wear; a skewed timing gear cover can disturb backlash and timing, increasing fuel consumption and emissions. In extreme cases, misalignment can trigger catastrophic gasket failure, shaft seal damage, or gear tooth chipping—events that drive unplanned downtime and costly repairs. Keeping connecting elements, especially the DOWEL PIN, in proper condition is therefore central to reliability and predictable maintenance planning.

Advantages of OEM spare parts suitable for connecting elements

DOWEL PIN OEM parts: performance, reliability, budget, and service life

OEM spare parts suitable for connecting elements deliver the dimensional fidelity and material consistency that complex engines demand. With DOWEL PIN OEM parts, tolerances are held across batches, hardness and microstructure match the design intent, and the pin-to-bore fit performs as calculated—so your clamp-load models and sealing strategies remain valid after overhaul. The result is stable alignment, correct torque retention, and fewer re-torque interventions.

From a performance and reliability standpoint, properly specified OEM spare parts suitable for connecting elements minimize fretting and micro-movement at interfaces, maintaining surface integrity and gasket compression. For budget and service life, they reduce rework and fitting time (no hand-finishing to make parts fit), limit collateral damage from misalignment, and extend intervals between top-end and gear-train inspections. In procurement, consistent specifications across engine families streamline stocking and reduce the risk of mixing incompatible geometry or metallurgy.

MOPA as a partner for OEM spare parts connecting elements

MOPA is an experienced and reliable partner for OEM spare parts connecting elements—including the DOWEL PIN—for diesel and gas engines. Purchasers and shipowners rely on our speed, quality, and security: fast quotations, short lead times from stock or networked supply, and documented conformity for critical items. We support marine engine and power plant operators with precise identification of the correct pin sizes and fits, as well as the matching bolts, studs, and washers required to restore joint integrity.

Our processes are built for secure trade of OEM parts: traceable sourcing, careful packaging to protect ground surfaces, and logistics solutions for urgent dockings or remote sites. Whether you need a single DOWEL PIN for a gearbox housing or a complete kit of connecting elements for a major overhaul, MOPA helps you execute maintenance with confidence and minimal downtime.

Conclusion: connecting elements with DOWEL PIN keep engines aligned and efficient

Connecting elements are essential to engine performance, and the DOWEL PIN is the key to repeatable, stable alignment across the whole service life. Choosing OEM spare parts suitable for connecting elements secures precision, protects your budget, and underpins long-term reliability—on every diesel or gas engine you operate.