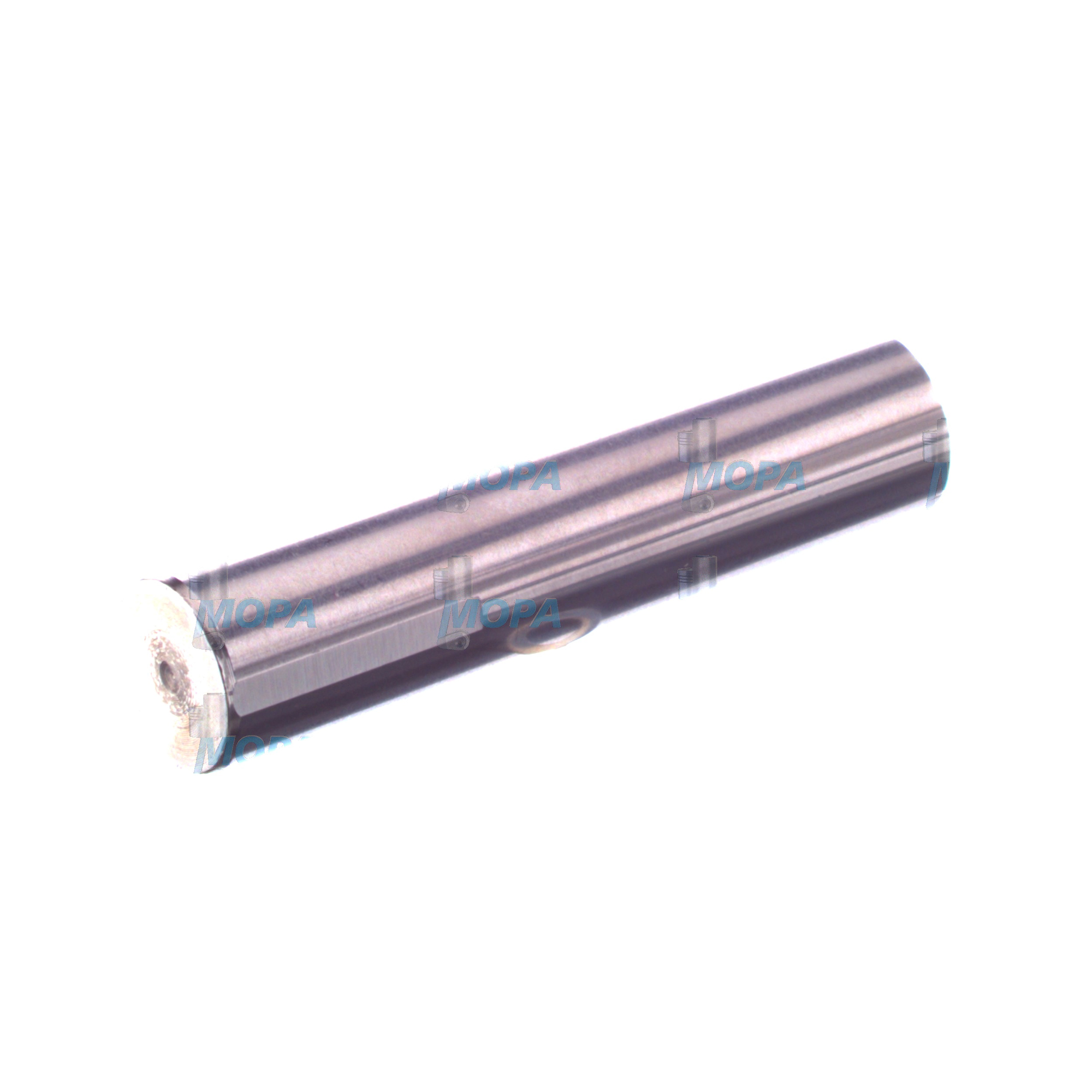

GUIDE PIN Connecting Elements for Reliable Engine Assemblies

Connecting elements are the unsung heroes of engine assembly. They include precise locating parts like the GUIDE PIN, along with bolts, studs, sleeves, and dowels that hold complex structures together. In heavy-duty diesel and gas engines, as well as in every marine engine room, these components ensure that housings mate correctly, shafts run true, and gaskets seal under extreme thermal and mechanical loads. Without accurately manufactured connecting elements, even the best-designed power unit will suffer from misalignment, vibration, and premature wear.

Within this category, the GUIDE PIN plays a pivotal role. It provides repeatable, micron-level location between mating parts—cylinder block and head, gear casing and block, bearing caps and saddles, or turbocharger casings—so that clamping forces from fasteners are applied evenly. A correctly specified GUIDE PIN for a diesel engine or marine engine simplifies service procedures, eliminates assembly errors, and protects critical interfaces from damage across countless maintenance cycles.

Technical function of GUIDE PIN connecting elements in diesel and marine engines

A GUIDE PIN is a precision-ground locating device that defines the exact relative position of two or more components before fasteners are tightened. In engine architecture, this function supports performance, efficiency, and safety in several ways:

First, it establishes concentricity and flatness between mating parts, preventing shear loading of bolts and avoiding fretting at interfaces. Second, it keeps gaskets compressed within their design window, helping to maintain combustion, coolant, and oil sealing at elevated temperatures. Third, it ensures that rotating and reciprocating assemblies—camshaft carriers, timing housings, and accessory drives—remain within designed run-out limits, safeguarding bearing life and reducing noise and vibration.

In practice, a GUIDE PIN OEM parts set is typically produced from alloy steel and heat-treated for hardness and wear resistance. The shank is ground to h6 or similar precision, pairing with an H7 bore so the fit can be slip-fit for serviceability or press-fit for permanent location. Lead-in chamfers, controlled fillet radii, and low surface roughness prevent galling of bores and aid repeatable assembly in tight spaces common to marine engine skids. Corrosion-resistant finishes or stainless materials are used where saltwater exposure is likely, and dimensional tolerances down to hundredths of a millimeter protect alignment over multiple thermal cycles.

Key characteristics and advantages of connecting elements:

· Precision alignment that protects interfaces and fasteners.

· Stable gasket compression for long-lasting sealing.

· Consistent torque paths and uniform load distribution.

· Repeatable maintenance with minimal assembly error risk.

· Materials and heat treatment matched to engine duty.

· Corrosion resistance for offshore and shipboard environments.

· Dimensional traceability for compliance and quality audits.

GUIDE PIN installation and performance factors

Performance depends on the correct pairing of pin diameter and bore tolerance, proper seating depth, and clean, burr-free interfaces. For a GUIDE PIN in a diesel engine timing case, inadequate seating can skew gear mesh and raise backlash; in cylinder head applications, poor alignment can distort fire ring loading and lead to blow-by. Lubrication during insertion, adherence to alignment fixtures, and adherence to manufacturer torque patterns are critical to preserve the location set by the pins as the joint is clamped.

Why GUIDE PIN connecting elements matter for engine reliability and service life

Because connecting elements define geometry, any wear, deformation, or corrosion in a GUIDE PIN can cascade into costly problems. Misalignment increases bearing load and accelerates fatigue in rotating parts. Gasket edge loading causes micro-leaks that progress to coolant-oil cross-contamination or combustion gas leakage. Fasteners may experience lateral shear they were never meant to carry, resulting in relaxation or fracture. Over time, these issues reduce engine efficiency, raise fuel consumption, and shorten overhaul intervals. Conversely, stable location delivered by robust connecting elements preserves shaft line geometry, keeps emissions equipment calibrated, and maintains predictable thermal growth behavior throughout the engine’s lifecycle.

Advantages of OEM spare parts suitable for connecting elements

Choosing OEM spare parts suitable for GUIDE PIN and related connecting elements ensures that the dimensions, metallurgy, and surface treatments match the engine designer’s intent. This alignment translates directly into performance, uptime, and lifecycle value:

· Tight tolerances and controlled roughness that maintain interference/slip-fit design targets.

· Proven heat treatment and case depth for wear resistance at service interfaces.

· Coatings and materials validated for fuel, oil, coolant, and salt atmosphere exposure.

· Consistent geometry across batches for predictable assembly and torque behavior.

· Full traceability and documentation to support maintenance records and audits.

· Reduced risk of rework, secondary damage, and unplanned downtime—protecting budget and schedule.

Whether you need a GUIDE PIN for a marine engine overhaul or GUIDE PIN OEM parts for a fleet of stationary gas engines, the correct specification safeguards sealing, alignment, and structural integrity with every service event.

MOPA as your partner for OEM spare parts connecting elements

MOPA supplies OEM spare parts suitable for connecting elements—including GUIDE PIN sets, alignment sleeves, studs, and dowels—for leading diesel and gas engine platforms. Customers rely on our speed, quality, and security in parts sourcing and trade. We provide responsive quotations, short lead times on stocked items, and coordinated logistics for shipboard and power-plant deliveries. Our quality-managed supply chain focuses on dimensional accuracy, material conformity, and documentation, helping purchasers and technical managers minimize risk during planned maintenance and urgent repairs. From a single GUIDE PIN for a cylinder head alignment to complete connection kits for major overhauls, MOPA supports reliable operations across marine and industrial applications.

Conclusion: GUIDE PIN connecting elements that protect performance

GUIDE PIN connecting elements define engine geometry and protect fasteners, gaskets, and bearings from avoidable stress. By using OEM spare parts suitable for connecting elements, operators maintain alignment, sealing, and repeatable assembly—improving performance and extending service life while controlling costs. MOPA delivers the speed and quality needed to keep diesel and gas engines running with confidence.