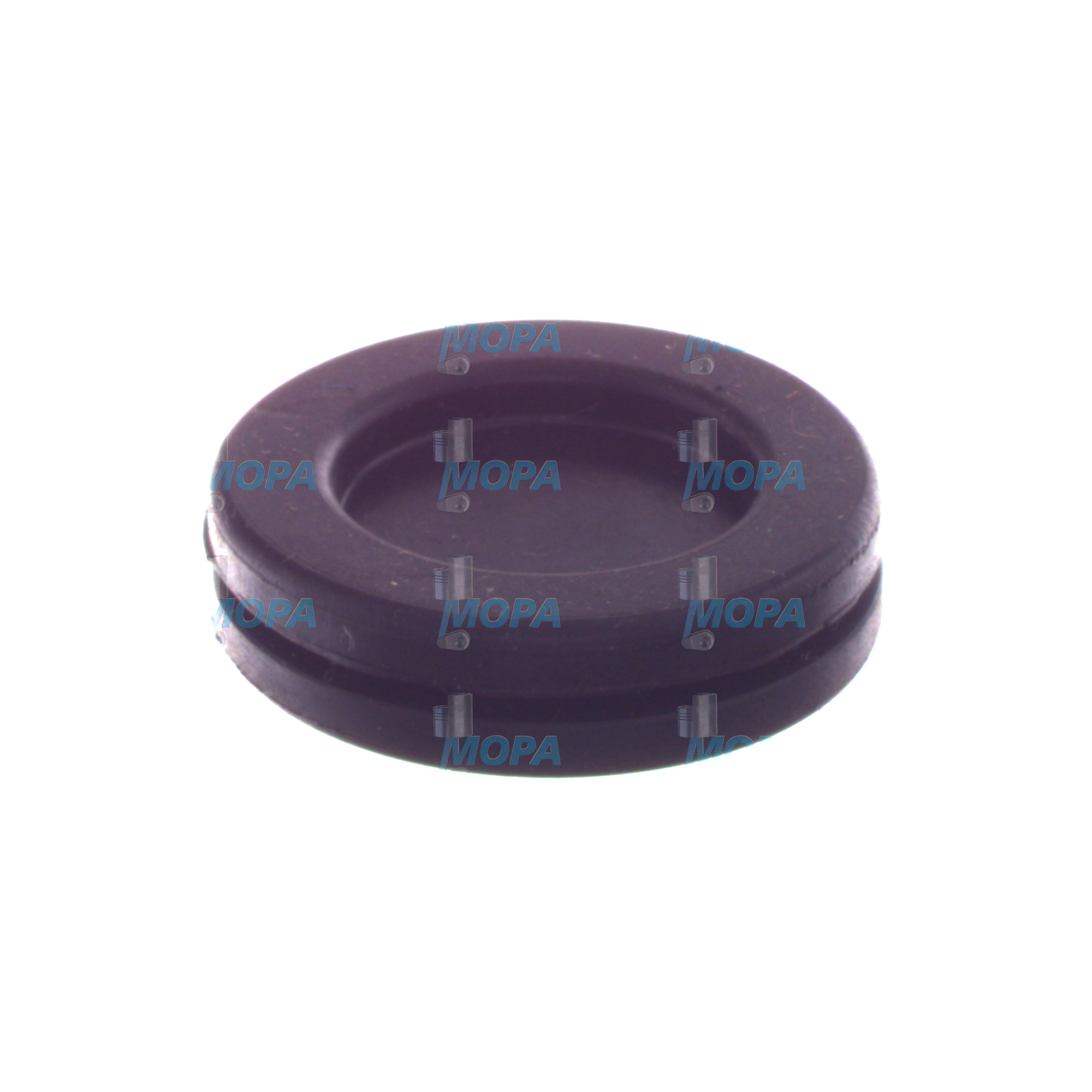

RUBBER GROMMET Connecting Elements for Marine and Diesel Engines

Connecting elements are the small but decisive components that keep engine assemblies aligned, sealed, and protected under demanding conditions. In propulsion and auxiliary power units, they include fasteners, clamps, brackets, spacers, bushings, couplings—and the often-overlooked RUBBER GROMMET that safeguards cables and hoses as they pass through deck plates, bulkheads, covers, and engine panels. Together, these parts maintain structural integrity, ensure clean routing of services, and protect sensitive interfaces from vibration, abrasion, and contamination.

In a marine engine or heavy-duty diesel engine, connecting elements face thermal cycling, continuous vibration, salt-laden air, oil mist, and aggressive fluids. Correctly specified parts make the difference between stable performance and costly downtime. A RUBBER GROMMET, for example, prevents chafing, seals out spray and dust, and isolates wiring from sharp edges—directly contributing to safety, reliability, and compliance. When deployed as OEM parts within a complete bill of materials, these elements deliver predictable fit and long service life.

Technical function of RUBBER GROMMET connecting elements in a marine engine

Connecting elements do far more than “hold things together.” They control load paths, maintain alignment between housings and brackets, distribute clamping forces, compensate for thermal expansion, and provide sealing and isolation where components interface. A RUBBER GROMMET in a marine engine or diesel engine panel supports several critical functions at once: it centers and protects cables or hoses, provides strain relief, absorbs vibration, and closes off the cut-out against water and dust ingress. The result is cleaner signals in sensor wiring, reduced mechanical wear on harnesses, and lower risk of leaks and short circuits.

Technically, grommets work by combining geometry and elastomer properties. The groove profile locks into the panel cut-out; the elastomer’s Shore hardness and compression set behavior define how well the grommet grips and seals. Material selection—NBR, EPDM, or FKM depending on exposure to oils, fuels, coolants, ozone, and heat—ensures durability. Properly toleranced components (e.g., per ISO 3302 for rubber tolerances and ISO 48-4 for hardness) maintain consistent performance across batches. For broader connecting elements such as bolts, washers, and clamps, factors like tensile class, surface treatment, and torque-to-tension characteristics preserve preload and prevent loosening under vibration.

- · Protects cables/hoses from edge abrasion and chafing.

- · Seals against spray, oil mist, and dust to reduce ingress.

- · Provides vibration isolation and strain relief.

- · Matches panel thickness and cut-out size for a secure fit.

- · Offers chemical and thermal resistance tailored to the medium.

- · Enhances reliability of sensors, controls, and auxiliaries.

- · Supports compliance with relevant marine and industry standards.

When integrated as RUBBER GROMMET OEM parts, the dimensional accuracy, compound consistency, and documented traceability simplify installation and ensure repeatable performance across fleets and maintenance cycles.

RUBBER GROMMET diesel engine reliability: why connecting elements matter

Reliability starts at the interfaces. If connecting elements are worn, mismatched, or incorrectly installed, small issues propagate into major faults. A hardened or cracked RUBBER GROMMET can expose harnesses to sharp edges, leading to insulation damage, intermittent signals, or short circuits. Missing or loose fasteners can allow misalignment, starter vibration, bracket fatigue, or premature bearing wear. Corroded clamps can compromise hose retention and cause leaks. Each of these failures undermines safety and availability, increases maintenance cost, and risks unplanned stops.

In diesel and gas engines, vibration and heat are constant. Elastomers must resist compression set to maintain sealing; metals must keep preload to resist loosening. Poorly performing connecting elements accelerate wear, intensify NVH, and erode electrical reliability in ignition or control systems. Regular inspection and timely replacement with correctly specified parts—especially high-risk items like grommets on fuel, oil, and control wiring routes—are essential to preserve service life and uptime.

Advantages of OEM spare parts suitable for Connecting Elements

Choosing OEM spare parts for connecting elements, including each RUBBER GROMMET in a harness route, provides measurable benefits for performance, reliability, budget, and service life. Fit-for-purpose elastomer compounds and exact dimensions mean correct seating in panel cut-outs without over-compression. Consistent tensile classes, coatings, and surface finishes on fasteners maintain torque and corrosion resistance. Documented materials and batch consistency reduce variability, simplifying maintenance planning and fleet standardization.

RUBBER GROMMET OEM parts: performance and cost control

OEM spare parts help operators avoid hidden costs such as premature rework, troubleshooting electrical faults from chafed wires, or downtime caused by leaks. Spec-grade grommets retain elasticity over thermal cycles, resist oil and fuel exposure, and provide stable sealing forces. For shipowners and technical purchasers, the result is lower total cost of ownership: fewer interventions, faster turnarounds, and predictable intervals aligned with engine overhauls. In addition, alignment with class and industry standards supports audits and documentation requirements without additional engineering effort.

MOPA: fast, secure supply of OEM parts for RUBBER GROMMET connecting elements

MOPA is an experienced and reliable partner for OEM spare parts connecting elements. We source and supply RUBBER GROMMET components, clamps, brackets, bolts, and related items for diesel and gas engines with speed, quality, and security. Our team supports technical cross-referencing by engine model and drawing number, provides traceable documentation, and consolidates multi-brand orders to reduce logistics complexity and lead times.

With strategically positioned stock, responsive quotations, and export-capable fulfillment, MOPA enables tight maintenance windows and minimizes vessel or plant downtime. From elastomer compounds suitable for marine engine enclosures to corrosion-resistant fasteners for hot-zone applications, we deliver the right specification—safely, quickly, and with dependable commercial handling throughout the trade of OEM parts.

Conclusion: RUBBER GROMMET connecting elements keep engines protected

Connecting elements, including the RUBBER GROMMET, are essential to the safe, efficient operation of marine and diesel engines. They protect interfaces, stabilize assemblies, and prevent avoidable failures.

By selecting OEM spare parts suitable for connecting elements, you secure consistent fit, proven material performance, and longer service life—while MOPA ensures fast, reliable supply for diesel and gas engines worldwide.