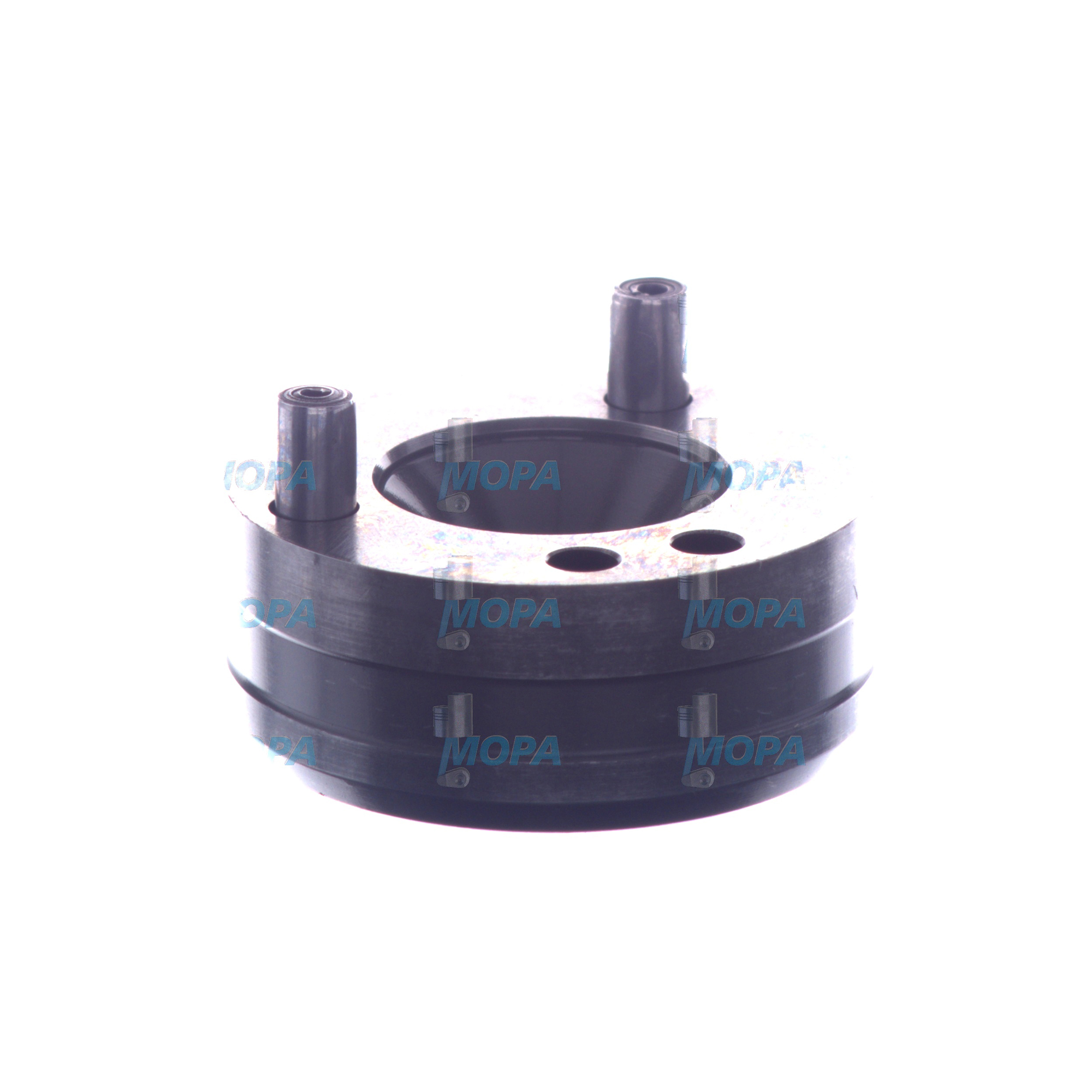

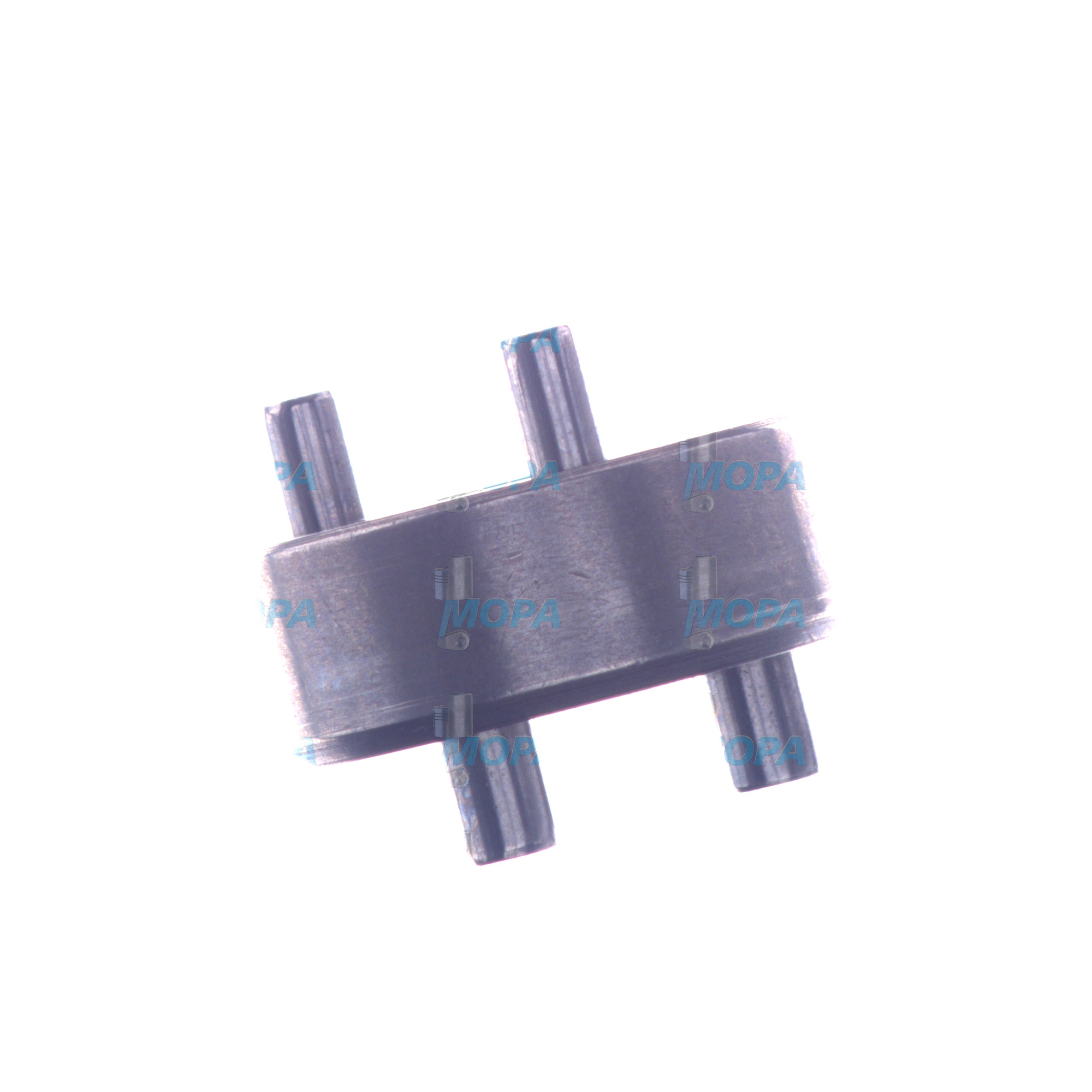

SPACER connecting elements for diesel and marine engines

Connecting elements are the bolts, studs, nuts, washers, pins, clamps, and spacers that mechanically join critical engine assemblies. In large diesel and gas engines—whether propulsion units on vessels or stationary power plants—these parts create the clamping force and alignment that keep cylinder heads sealed, turbochargers stable, auxiliaries aligned, and housings free from movement. As precision mechanical interfaces, connecting elements translate torque into predictable preload, preserve geometry under thermal cycling, and safeguard sealing surfaces against combustion and fluid pressures.

Within this category, the SPACER component has a special role: it defines exact axial distances between mating parts, isolates loads, prevents interference, and maintains alignment through the full temperature range of the engine. Correctly specified spacers, together with high-strength fasteners, convert design calculations into real-world reliability—directly influencing power density, emissions stability, and service intervals.

Technical function of connecting elements and SPACER in diesel engine and marine engine assemblies

In an engine, connecting elements create a controlled clamping system. Studs and bolts generate preload that compresses gaskets, seats bearings, holds manifolds, and secures casings. Nuts and washers distribute load and stabilize friction. Dowel pins and sleeves provide precise location, while a SPACER marine engine application ensures fixed standoff distances in gear trains, pump drives, charge-air ducts, and accessory brackets. Together, these parts deliver stiffness where it is needed and compliance where it is safe—mitigating vibration, preventing micro-movement, and maintaining concentricity.

Load transfer and preload mechanics

Engine fasteners work by stretching slightly to create spring-like clamping forces. Correct preload protects joints from separation and fretting, even under peak firing loads. Technicians apply torque-and-angle methods or hydraulic tensioning to achieve repeatable results, accounting for friction coefficients, lubrication, and thread geometry. Spacers in a SPACER diesel engine assembly prevent over-compression of soft components, keep pulley planes co-linear, and maintain critical backlash in timing gearsets—improving efficiency and reducing noise. The right combination of fastener grade, thread engagement, and spacer thickness stabilizes the joint throughout start-stop cycles and high thermal gradients.

Materials, coatings, and corrosion control

High-strength alloy steels (per ISO/ASTM classes) are common for bolts and studs; stainless or nickel alloys are used in hot or corrosive zones. Surface treatments—phosphate, zinc-nickel, or dry-film lubricants—control friction scatter and resist salt-laden atmospheres typical of marine duty. Precision-ground spacers and bushings hold tight tolerances on thickness, flatness, and perpendicularity to protect bearing life and seal integrity. Robust metallurgy and coatings directly influence long-term torque retention, fatigue life, and resistance to galling.

- · High-strength fasteners with controlled preload.

- · Precision SPACER components for exact axial distances.

- · Corrosion-resistant coatings for marine service.

- · Tight tolerances for alignment and sealing integrity.

- · Proven fatigue performance in cyclic engine loads.

- · Dimensional stability across wide temperature ranges.

- · Traceability and consistent quality for maintenance planning.

Importance for engine operation and service life

Reliable connecting elements are foundational to engine durability. Loss of preload from wear, relaxation, or corrosion can trigger gasket blowouts, coolant or lube oil leaks, and exhaust leakage that accelerates turbocharger and aftertreatment degradation. Misaligned components raise vibration levels, increase bearing loads, and cause gear tooth edge wear—eroding efficiency and risking unplanned downtime. Fatigue cracks in bolts or studs can propagate silently until a sudden joint separation occurs. Precision SPACER elements prevent misalignment in couplings and auxiliaries; if they are out of tolerance, belts wander, pulleys overheat, and shaft seals fail prematurely. In short, well-specified connecting elements protect performance, emissions stability, and safety while extending service intervals.

Why OEM spare parts suitable for connecting elements matter, including SPACER OEM parts

Selecting OEM spare parts suitable for connecting elements minimizes dimensional deviation and material variability. That means threads engage at the designed pitch diameter, head geometries match tool interfaces, friction coefficients are predictable, and spacer thickness is exactly what the drawing demands. The result is consistent preload, stable sealing, and repeatable assembly procedures—key for class-approved marine maintenance and fleet standardization. For purchasers, this translates into fewer reworks, shorter docking times, and lower lifecycle cost through reduced wear on related components.

With SPACER OEM parts and matched fasteners, technicians can use published tightening data with confidence, ensuring that gaskets, bearings, and housings see the intended clamping force. Traceable materials and controlled heat treatment underpin fatigue strength, while coatings specified for diesel engine environments preserve torque retention in salt spray and high-temperature zones. Investing in such parts supports long-term reliability, predictable maintenance, and optimized total cost of ownership.

MOPA: fast, high-quality, and secure supply of OEM parts for diesel and gas engines

MOPA is an experienced partner for OEM spare parts connecting elements—covering bolts, studs, nuts, washers, dowels, and SPACER elements for diesel and gas engines. Customers benefit from rapid RFQ handling, short lead times from strategic stock, and rigorous quality control with documentation and batch traceability. Whether you operate a single vessel or manage a fleet, MOPA streamlines procurement with accurate cross-referencing, kitting for planned overhauls, and secure logistics that keep your maintenance on schedule. Our focus on specification fidelity and dependable supply helps shipowners and power plant operators maintain performance with confidence.

Conclusion on SPACER connecting elements

SPACER connecting elements are critical to alignment, sealing, and structural integrity in diesel and marine engines. When these components are precisely manufactured and correctly installed, they protect performance, efficiency, and safety across the engine’s service life.

OEM spare parts suitable for connecting elements—especially SPACER components matched to the application—deliver the consistency and durability that keep assets running reliably and cost-effectively. With MOPA, you secure fast, quality-assured access to the parts your engines depend on.