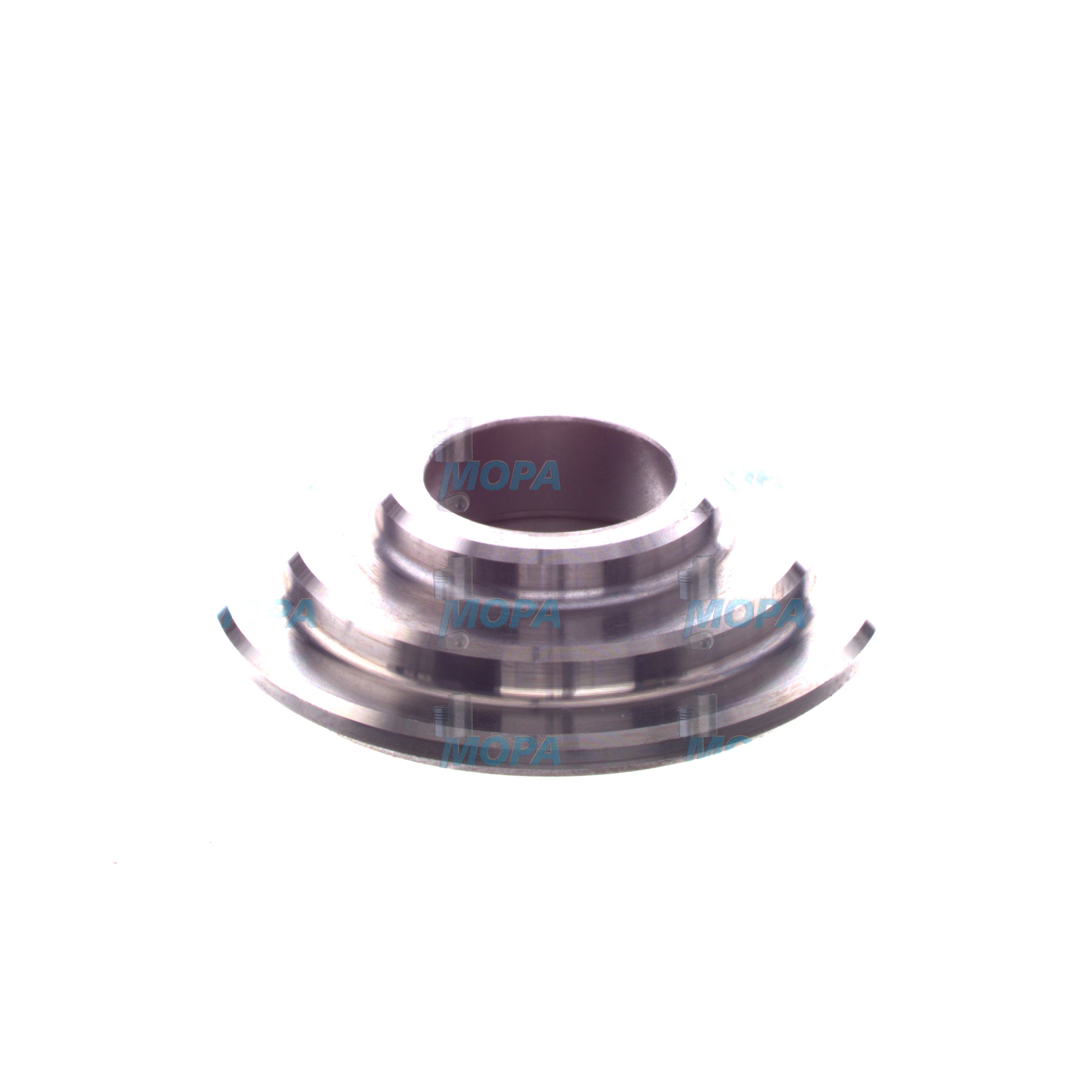

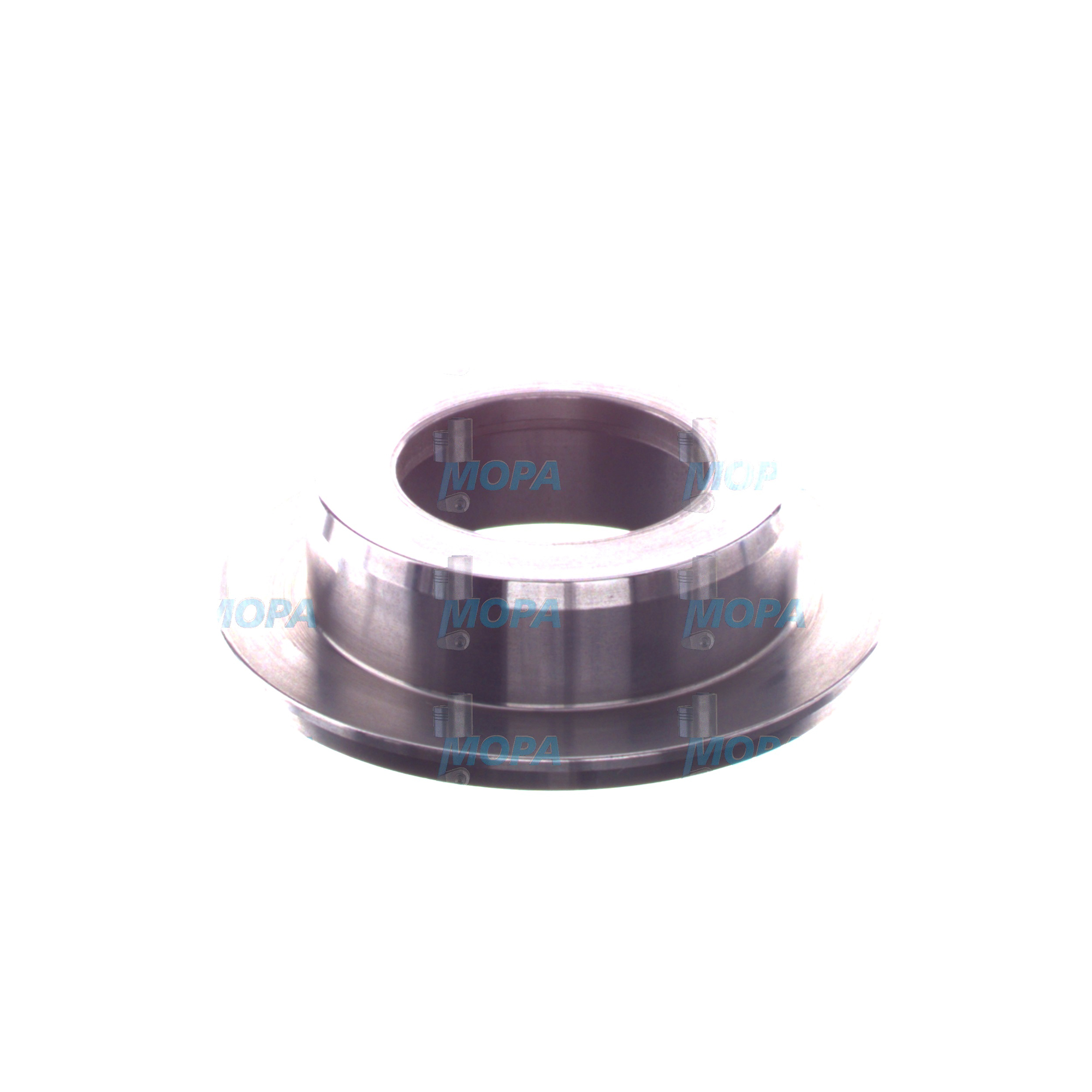

SPRING CAP Connecting Elements for Heavy-Duty Diesel and Marine Engines

Connecting elements are the backbone of every combustion engine assembly. This category includes all fasteners and retention components that clamp, locate, and secure critical parts under dynamic loads: bolts and studs for cylinder heads, nuts and washers for flanged joints, pins and clamps for accessory drives, and precision retainers such as the SPRING CAP in the valve train. In diesel and marine engine applications, these components maintain structural integrity across high pressures, temperature gradients, and vibration—conditions that demand consistent preload, exact tolerances, and materials engineered for fatigue resistance. Without reliable connecting elements, sealing fails, timing drifts, and catastrophic mechanical damage becomes a real risk.

Technical function of Connecting Elements and SPRING CAP in marine and diesel engines

In an engine, connecting elements convert torque into clamp force, hold alignment between mating surfaces, resist cyclic stresses, and preserve the geometry that combustion and motion control depend on. Cylinder head studs and nuts maintain gasket compression against firing pressure peaks; main bearing bolts hold crankcase rigidity; exhaust manifold fasteners keep joints sealed despite thermal expansion; and the SPRING CAP (often called a valve spring retainer) locks the valve spring onto the valve stem, transferring spring force to keep the valve seated and under control at speed.

The SPRING CAP in a diesel engine or marine engine works together with collets/keepers to grip the valve stem groove. It centralizes the valve spring, ensures correct installed height, and supports the high-frequency load cycles that occur at every cam event. By securing the spring, the SPRING CAP prevents valve float at high RPM, stabilizes valve timing, and minimizes impact loads on the seat—key to performance, fuel efficiency, and emissions stability. In large-bore engines, the cap’s metallurgy and surface finish must withstand high Hertzian contact stresses at the keeper interface while resisting fretting and micro-pitting. Precision geometry—concentricity, chamfer angles, and keeper fit—directly affects spring alignment and life.

Across the engine, fasteners must deliver repeatable preload. That requires controlled tightening methods (torque-angle, hydraulic tensioning), correct friction conditions, and fastener materials with known yield strength and ductility. Coatings such as phosphate, nitriding, or zinc-flake may be used to manage friction, corrosion, and galling. For the SPRING CAP specifically, high-strength alloy steels, through-hardening or case-hardening regimes, and shot peening can elevate fatigue limits. When sourced as OEM parts, each cap is matched to a specific valve train design, spring rate, and keeper geometry, ensuring that the clamping system performs as modeled by the engine maker.

- · High tensile and fatigue strength under cyclic loads.

- · Stable preload for sealing and alignment in harsh duty.

- · Precision tolerances for fit, concentricity, and installed height.

- · Thermal and corrosion resistance suitable for marine environments.

- · SPRING CAP design optimized for valve control and anti-float.

- · Proven materials and heat treatment for long service life.

- · Traceability and specification match to OEM parts.

Why Connecting Elements and SPRING CAP are critical for engine reliability

Reliability hinges on the health of connecting elements. Loss of preload in head studs can lead to gasket blow-by, coolant contamination, and power loss. Fatigue cracks in main bearing bolts compromise crank alignment, accelerating wear and risking seizure. Exhaust joint fastener relaxation causes hot gas leakage and turbocharger inefficiency.

A failed SPRING CAP in a marine engine is especially severe: if the retainer or keepers lose grip, the valve can drop into the combustion chamber, causing piston impact, bent rods, and extensive collateral damage. Even before failure, wear at the keeper interface can change installed height, shifting valve timing and reducing compression. Symptoms include misfire under load, increased fuel consumption, and rising exhaust temperatures. Regular inspection for fretting marks, surface cracking, and dimensional drift, coupled with adherence to replacement intervals, prevents these outcomes.

Advantages of OEM spare parts suitable for Connecting Elements and SPRING CAP

Using OEM spare parts suitable for connecting elements delivers predictable clamp force, consistent fatigue performance, and exact fit across the engine. The dimensional accuracy and tested metallurgy that come with OEM parts reduce setup time and eliminate the hidden costs of rework or early failure. For a SPRING CAP, OEM-grade geometry ensures correct keeper engagement, precise installed height, and compatibility with the specified spring rate—protecting the valve train against float and abnormal wear.

From a budget and lifecycle perspective, the value is clear: fewer unplanned stops, less collateral damage, and longer service intervals. For safety and compliance, OEM parts preserve the as-designed joint integrity that classification societies and engine builders expect. Documentation, batch traceability, and repeatable properties simplify audits and maintenance planning, especially in critical diesel engine fleets.

SPRING CAP marine engine and diesel engine OEM parts: performance you can measure

When you select OEM parts for the SPRING CAP and related connecting elements, you secure known S–N fatigue behavior, validated heat treatment, and coatings tuned for your operating environment. The result is stable valve control, maintained sealing forces, and smoother operation across load profiles—from harbor maneuvering to full sea power.

MOPA as your partner for OEM spare parts Connecting Elements and SPRING CAP

MOPA is an experienced, reliable partner for OEM spare parts in the category of connecting elements, including the SPRING CAP for diesel and gas engines. We combine speed in quotation and delivery with stringent quality processes and secure, traceable sourcing. Our portfolio covers a wide range of applications—auxiliary gensets to main propulsion—and our team helps match each component to the exact engine reference, ensuring technical compliance and optimal performance.

With MOPA, you gain streamlined logistics, documentation support, and expert guidance on fastener and valve train selection, so your vessels and power plants return to service quickly and stay there longer.

Conclusion: SPRING CAP and Connecting Elements with OEM parts

Connecting elements—especially the SPRING CAP in the valve train—are essential to performance, efficiency, and safety in marine engine and diesel engine operations. Selecting OEM spare parts suitable for these components preserves design intent, reduces downtime, and extends service life. MOPA supplies the speed, quality, and security you need to keep critical assets running at peak reliability.