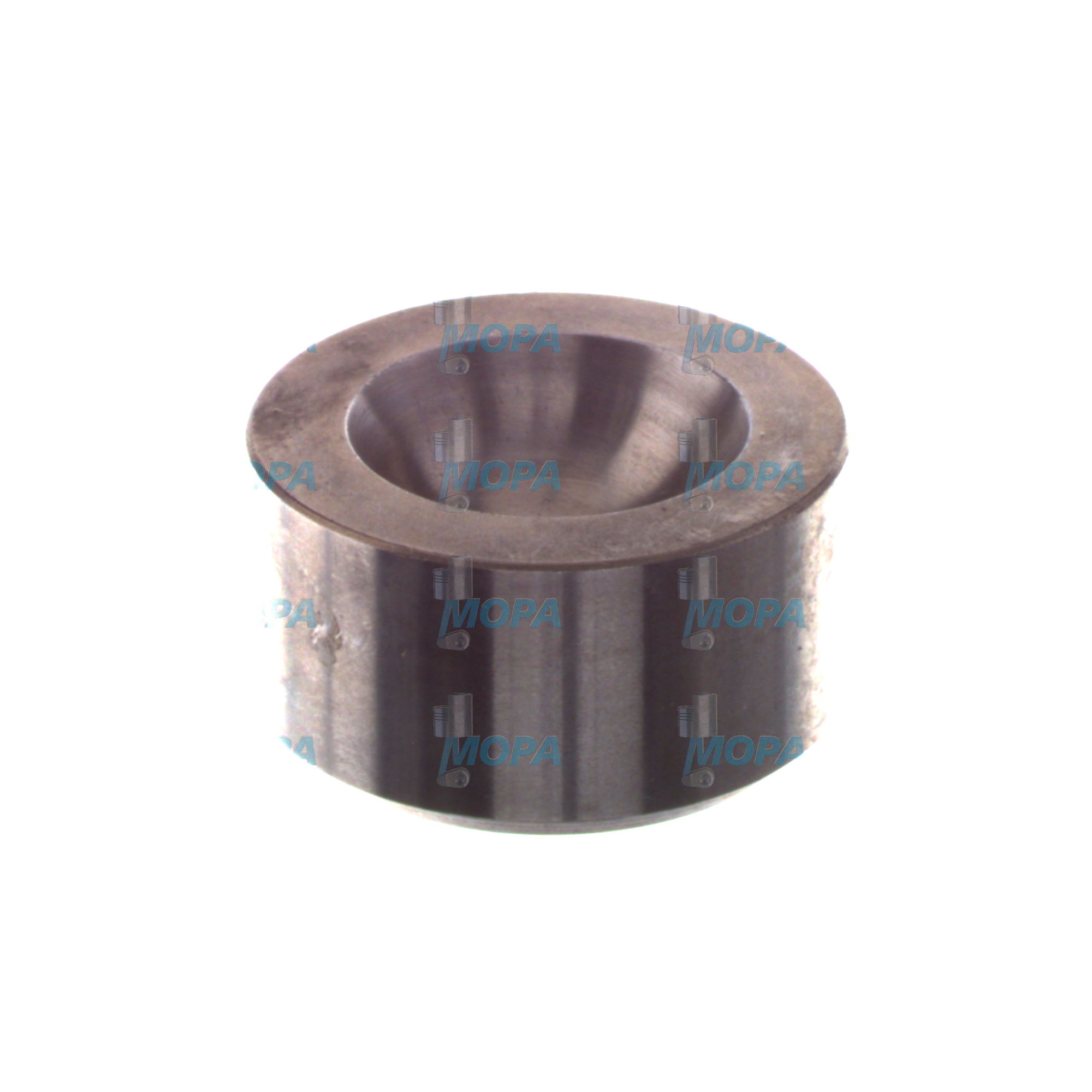

THRUST PAD stability with precision Connecting elements for marine and diesel engines

Connecting elements are the engineered fasteners and couplers that mechanically join the major assemblies of an engine: bolts and studs for cylinder heads and main bearing caps, nuts and washers, dowel pins for alignment, keys and retaining rings for shafts, clamps and couplings for auxiliaries, as well as threaded rods and special screws. In marine engine and diesel engine applications, these parts secure the structure that carries dynamic loads, thermal expansion, vibration, and torsional forces. By holding housings, bearing shells, and frames in strict alignment, connecting elements underpin axial control at the crankshaft and, ultimately, the stable operation of the THRUST PAD and thrust bearing set.

Technical function of Connecting elements and the THRUST PAD in a marine engine

The core job of connecting elements is to deliver predictable clamping force that keeps components in position throughout the engine’s operating envelope. When correctly specified and installed, a bolt or stud is elastically stretched to create a defined preload. That preload resists separation of joint faces under combustion pressure, inertia loads, and shaft reactions. For example, main bearing cap bolts maintain the housing crush that fixes bearing shells; the resulting geometry controls journal alignment and the axial location of the crankshaft against the THRUST PAD in a marine engine.

Performance and efficiency hinge on this preload being accurate and repeatable. Torque-and-angle, hydraulic tensioning, and controlled lubrication regimes are applied to achieve target clamp loads while accounting for thread friction and surface finish. Materials are chosen for strength class and temperature capability (e.g., high-grade alloy steels for 10.9/12.9 performance), while coatings such as phosphate or zinc-flake improve corrosion resistance and torque scatter. Locking features—prevailing-torque nuts, serrated washers, mechanical locks—combat self-loosening from vibration and pulsation.

These fasteners also enable safe axial load transfer. In a diesel engine, propeller thrust or driven-machine axial forces travel through the crankshaft to the thrust bearing. If the block, bedplate, and bearing carriers are clamped and aligned by robust connecting elements, the oil-film wedge on the THRUST PAD in a diesel engine remains stable, minimizing friction losses and metal-to-metal contact. Conversely, insufficient preload can distort housings, reduce bearing crush, and compromise thrust-face geometry.

- · High-strength materials and controlled heat treatment for predictable preload.

- · Precision threads and seating faces for consistent torque-to-tension conversion.

- · Surface protection tailored to salt-laden marine environments.

- · Vibration-resistant locking to prevent self-loosening over long duty cycles.

- · Accurate alignment via dowels and fitted bolts for bearing and THRUST PAD stability.

- · Compatibility with THRUST PAD OEM parts and bearing housings.

Why Connecting elements matter for engine reliability and THRUST PAD life

Reliability and service life depend on maintaining joint integrity. Overstressed, corroded, or fatigued connecting elements can lose preload or fail outright, leading to gasket leakage, fretting on joint faces, bearing cap movement, and loss of bearing crush. Even small losses in clamping force can increase crankshaft misalignment and axial endplay, accelerating wear on the thrust bearing. The THRUST PAD then sees uneven loading and oil-film collapse, which may manifest as wiping of the white metal, elevated temperatures, higher friction, and rising fuel consumption. In extreme cases, broken fasteners or walked caps can trigger catastrophic bearing damage and unplanned downtime—an unacceptable risk for shipowners and power plant operators.

Routine inspection, torque verification, and timely replacement of connecting elements are therefore critical to safeguard the axial load path and protect the THRUST PAD, journals, and gear trains. Specifying the correct class, length, thread pitch, and coating for the operating environment is equally important.

Advantages of OEM spare parts suitable for Connecting elements and THRUST PAD OEM parts

Using OEM spare parts suitable for connecting elements ensures that every fastener and coupler meets the original engineering intent for metallurgy, heat treatment, dimensional tolerance, and thread geometry. This fidelity delivers consistent preload under specified torque or tensioning procedures and preserves the precise alignment needed by the crankshaft and THRUST PAD OEM parts.

For performance, reliability, budget, and service life, the benefits are tangible: lower torque scatter, reduced re-tightening frequency, and stable joint compression at elevated temperatures. Traceable production and application-specific coatings mitigate corrosion in marine atmospheres, cutting the risk of seizure and galling during service. The outcome is dependable uptime and lower total lifecycle cost through fewer incidents, less collateral damage to bearings and housings, and optimized fuel efficiency due to preserved mechanical alignment.

THRUST PAD in diesel engine assemblies: why correct connecting elements matter

When the correct OEM spare parts suitable for connecting elements are installed in a diesel engine, axial forces are transmitted cleanly to the thrust bearing without skewing or edge loading. Bearing crush remains within specification, the oil film on the THRUST PAD is stable, and thermal growth is accommodated by joints designed for elastic behavior—key to long intervals between overhauls.

MOPA — fast, secure supply of OEM Connecting elements and THRUST PAD components

MOPA is an experienced and reliable partner for OEM spare parts suitable for connecting elements. We support operators of diesel and gas engines with rapid sourcing, proven quality, and transactional security. From cylinder head studs and main bearing cap bolts to precision dowels and specialized nuts that interface with the THRUST PAD assembly, MOPA provides parts with full technical documentation, consistent lead times, and responsive logistics—reducing downtime and simplifying planned maintenance.

Whether you need a critical-path shipment for a marine engine in dry dock or a scheduled replenishment for a power plant, our team helps you standardize on the correct OEM parts and installation practices, safeguarding alignment, preload, and axial control.

Conclusion: Connecting elements and THRUST PAD performance

Connecting elements form the backbone of engine integrity, securing the geometry that protects the THRUST PAD and the entire rotating assembly. Selecting and installing OEM spare parts suitable for connecting elements preserves preload, alignment, and axial load management—delivering dependable performance and long service life with optimized operating costs.