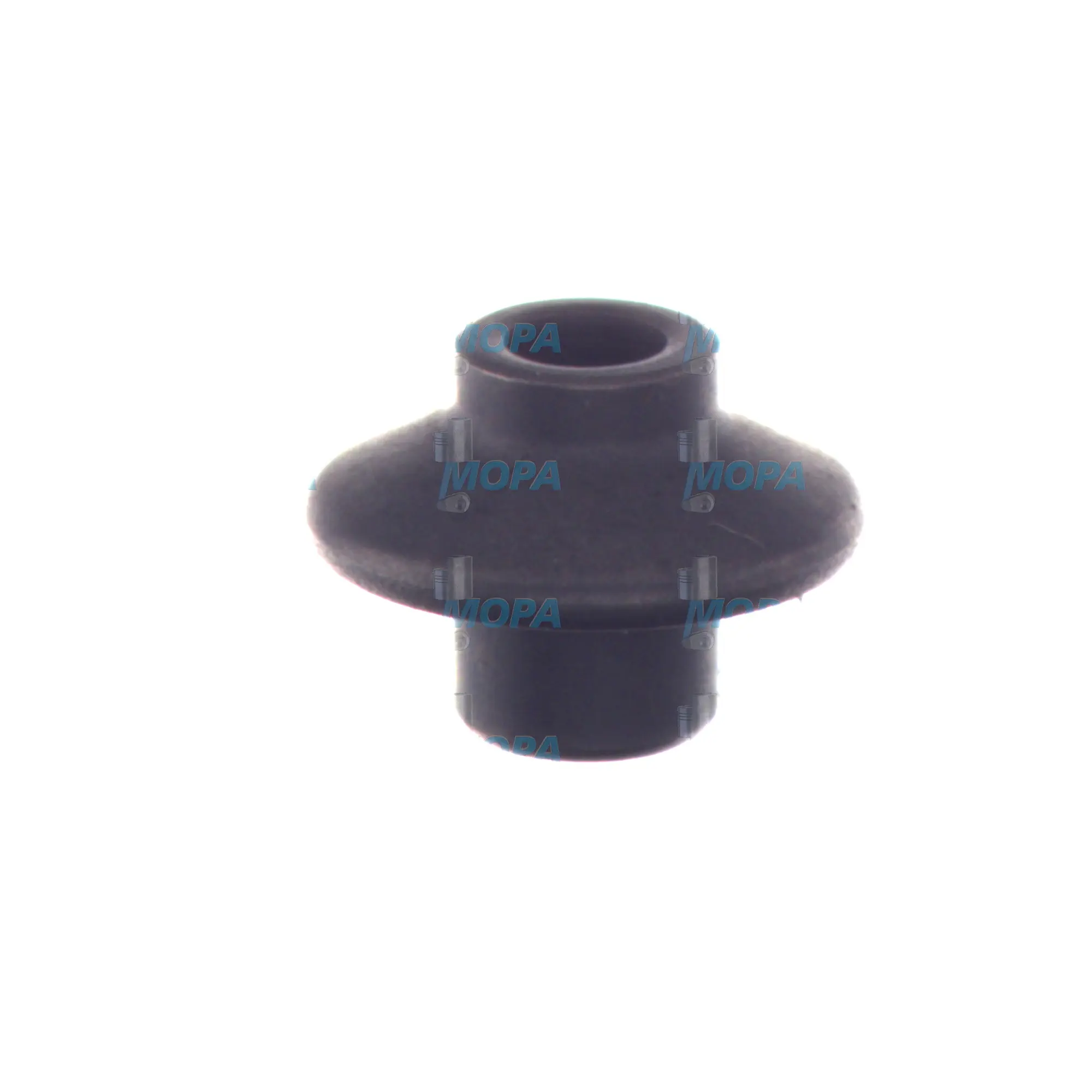

THRUST PIN Connecting Elements for Marine and Diesel Engines

Connecting elements are the precision-made fasteners, pins, keys, sleeves, and retainers that transmit forces and position critical subsystems inside an engine. They tie rotating and reciprocating groups together, align housings, and safeguard clearances under extreme thermal and mechanical loads. Within this category, the THRUST PIN stands out as a small but decisive component that converts axial forces into controlled movement and reliable support. For shipowners, power plant operators, and maintenance planners, robust connecting elements are fundamental to dependable uptime and predictable lifecycle costs.

In high-output marine engine and industrial diesel engine platforms, connecting elements protect gear trains, valve gear, fuel injection systems, and couplings from micro-movement and misalignment. By holding tolerances, resisting wear, and preserving geometry at interfaces, they directly influence performance, efficiency, and safety. Selecting proven designs and materials—and replacing them on schedule with dimensionally correct OEM parts—prevents unplanned stoppages and costly secondary damage.

Technical function of THRUST PIN connecting elements in diesel and marine engines

A THRUST PIN is a hardened, ground cylindrical element that transmits or limits axial load between mating components. In a diesel engine or marine engine, it typically serves as an axial stop, locator, or load path in assemblies such as timing gear carriers, governor and actuator linkages, fuel injection control racks, clutch or coupling housings, and turbocharger wastegate mechanisms. By ensuring repeatable end-play and precise stroke limits, the THRUST PIN stabilizes motion, protects bearings and journals from overload, and keeps timing and fuel delivery within specification.

On the materials side, the pin is generally produced from alloy steel with case hardening or through-hardening to resist brinelling, galling, and fretting. Fine-ground surfaces (often Ra ≤ 0.2–0.4 μm) and tight cylindricity preserve the oil film and minimize wear against bores or seats. Correct hardness profiles allow the surface to withstand contact stress while the core absorbs shock loads. When specified as OEM parts, THRUST PIN geometries align exactly with mating features—chamfers, reliefs, and lead-in radii—ensuring consistent assembly force and long-term fit.

Functionally, a THRUST PIN helps the engine in three ways:

· It carries axial force to a robust path, preventing thrust from being taken by sensitive components.

· It sets positive stops, so actuators and gear trains do not over-travel at high RPM.

· It maintains alignment, which stabilizes vibration signatures and reduces noise and losses.

In practice, that means steadier governor response, repeatable injection control, and reliable coupling engagement. The result is smoother operation, improved fuel efficiency, and better protection of critical interfaces during transient loads, cold starts, and heavy seas.

Key characteristics of Connecting Elements (incl. THRUST PIN):

· High-strength steel and precise heat treatment.

· Ground surfaces for low friction and low wear.

· Tight tolerances for exact fit and alignment.

· Corrosion control via material and finish selection.

· Stable performance under thermal cycling.

· Drop-in compatibility as OEM parts for known assemblies.

Importance of Connecting Elements and THRUST PIN for engine operation

Connecting elements are foundational to reliability. When a THRUST PIN or related pin/key wears, elongates a bore, loses hardness, or develops fretting marks, the immediate effects are greater clearances and uncontrolled movement. In a marine engine, that can manifest as gear train chatter, governor hunting, inaccurate rack travel, or premature wear on bearings and thrust washers. In a diesel engine driving a generator, it may cause timing drift, elevated vibration, and higher specific fuel consumption.

Unchecked degradation can cascade: axial float increases impact loads, which accelerates pitting and scoring on mating faces. Misalignment propagates through couplings and shafts. In extreme cases, pins can seize or shear, leading to sudden loss of actuation, trips, or internal damage that multiplies downtime and repair costs. Routine inspection and timely replacement with correctly specified connecting elements protect performance and extend service life.

Advantages of OEM spare parts suitable for Connecting Elements

For THRUST PIN applications, OEM spare parts provide the dimensional fidelity, metallurgy, and surface quality needed to match the engine maker’s design intent. That precision is critical where a few microns of clearance separate smooth operation from accelerated wear. The benefits extend across performance, reliability, budget, and service life:

· Consistent tolerances: Restores designed end-play and stroke limits without rework.

· Verified materials: Proper hardness gradients and core toughness resist shock and fretting.

· Optimized surfaces: Ground finishes reduce heat, scoring, and energy losses.

· Traceability and documentation: Clear specs for audits and maintenance records.

· Lower total cost of ownership: Longer intervals between interventions and fewer secondary failures.

· Predictable fit with mating parts: Reduced assembly time and minimized risk of dimensional mismatch.

THRUST PIN OEM parts: performance and lifecycle gains

When a THRUST PIN is sourced as OEM parts for the intended assembly, clearances and lead-in geometries match the bore, seat, or carrier exactly. That prevents edge-loading, maintains hydrodynamic lubrication, and stabilizes vibration behavior. Over the lifecycle, this precision yields steadier governor and injection dynamics, fewer alarm events, and cleaner wear patterns—tangible gains for uptime and budget control.

MOPA: your partner for OEM spare parts Connecting Elements and THRUST PIN

MOPA supplies OEM spare parts for connecting elements—including THRUST PIN solutions—for diesel and gas engines used at sea and on land. Customers rely on fast response, dependable quality, and secure global logistics that keep maintenance windows short and predictable. From single-pin replacements to full kits aligned with major overhauls, MOPA delivers correctly specified components with technical clarity and professional documentation.

Our team supports purchasers and technical decision-makers with cross-references, dimensional checks, and material data so that each THRUST PIN and associated connecting element arrives ready for installation. Speed, quality, and security define our approach to the trade of OEM parts.

Conclusion: Connecting Elements and THRUST PIN OEM parts

Connecting elements—and the THRUST PIN in particular—are small components with a major impact on engine alignment, timing accuracy, and wear control. Selecting and installing OEM spare parts suitable for these components safeguards performance, extends service life, and optimizes budget over the engine’s operating horizon.