WOODRUFF KEY connecting elements for diesel and marine engines

Connecting elements are precision-engineered components that mechanically link, locate, and secure rotating and static parts inside an engine. From keys and pins to circlips and retaining rings, they transmit torque, maintain alignment, and keep critical subassemblies in position. In large diesel and gas engines—especially in marine engine applications—these small parts play an outsized role: they protect the driveline from slippage, preserve timing accuracy, and stabilize loads that would otherwise accelerate wear. Among these components, the WOODRUFF KEY stands out as a compact, self-aligning solution for hub-to-shaft connections in pulleys, gears, and couplings.

Technical function: Connecting elements and the WOODRUFF KEY in a diesel engine

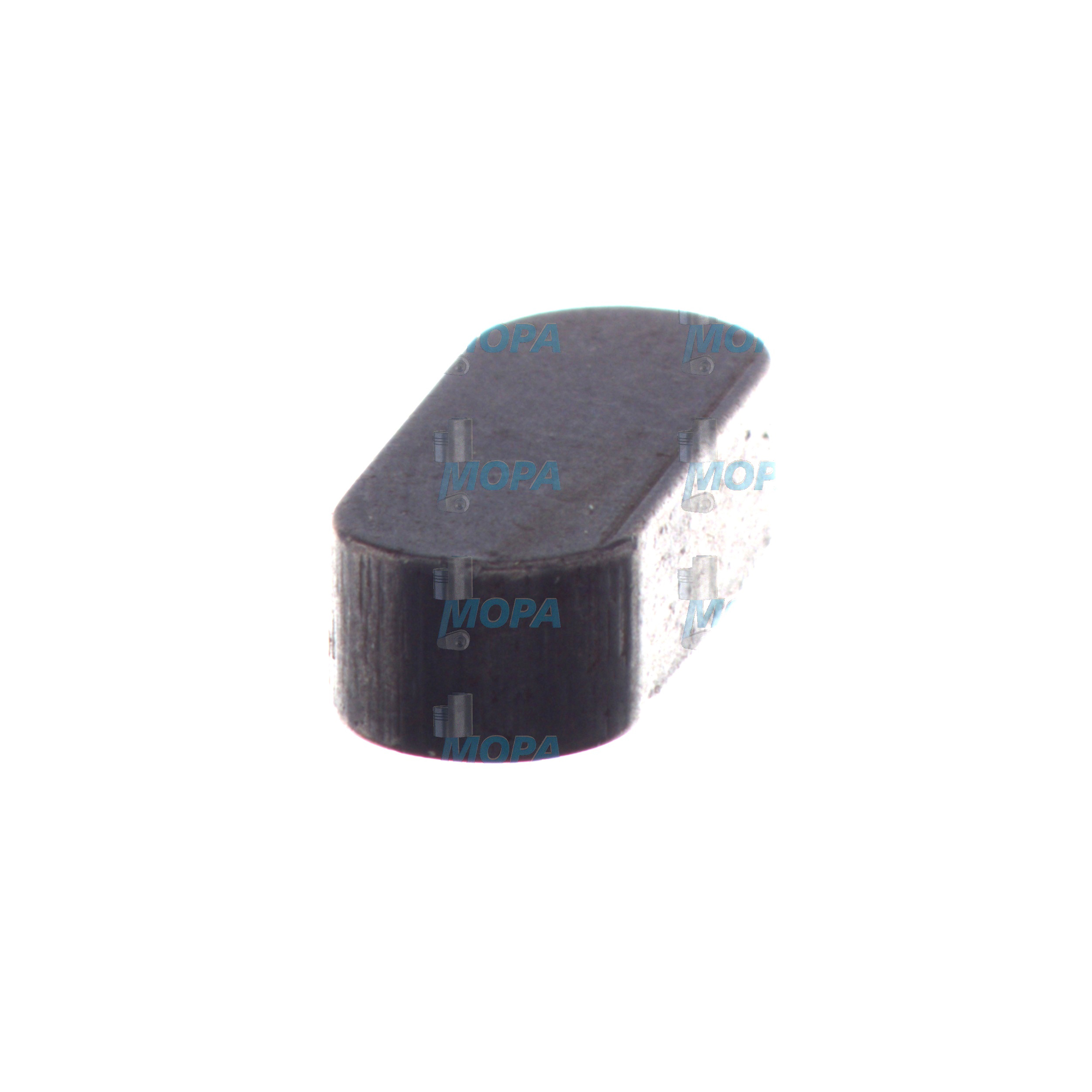

Connecting elements ensure that power generated by combustion is reliably transferred through the crankshaft to accessory drives, camshafts, pumps, and generators. The WOODRUFF KEY is a semi-circular key seated in a milled keyseat on the shaft. Its curved profile allows the hub to self-align as it is pressed onto a straight or tapered fit, creating a secure, precise connection that resists torque and shock loads. In a diesel engine, such a key commonly secures a gear on the crankshaft or camshaft, locks a fuel injection pump drive, or fixes an alternator or water pump pulley. In a marine engine, the WOODRUFF KEY helps maintain timing integrity under fluctuating load and vibration, preventing micro-movements that lead to fretting or hub wobble.

Compared with straight parallel keys, the WOODRUFF KEY distributes stress more uniformly at the hub interface and reduces the likelihood of key “rocking” during transient loads. Because the key’s top can sit flush with the shaft while the curved base anchors solidly in the keyseat, installation tolerances are easier to manage, which is especially valuable during field service. For best results, technicians verify that the hub fully seats against the shaft shoulder, the key protrusion is within specification, and contact pattern on the key flanks is even. In addition to keys, other connecting elements—dowel and taper pins for alignment, circlips for axial retention, and precision studs/nuts for clamping—work together to stabilize assemblies and preserve efficiency.

Material selection and sizing matter. Engine builders specify hardened steels for keys and pins, with controlled hardness to balance shear strength and ductility. Surface finishes and coatings suitable for salt-laden marine atmospheres help combat corrosion, while compliant geometries (fillet radii, chamfers) minimize stress concentrations in the keyseat. WOODRUFF KEY OEM parts that follow established standards (e.g., DIN 6888) ensure dimensional accuracy across sizes and brands, supporting repeatable service procedures and prolonged service life.

Key characteristics and advantages of connecting elements

· Secure torque transmission without slippage

· Self-aligning WOODRUFF KEY geometry for stable hub seating

· Tight tolerances for timing-critical diesel engine drives

· Robust materials and heat treatment for high-cycle fatigue

· Corrosion protection tailored for marine engine environments

· Clean, repeatable assembly and disassembly in service

· Reduced vibration and fretting at hub/shaft interfaces

· Compatibility with OEM parts across diesel and gas platforms

Importance for engine operation and service life

When connecting elements are in top condition, the driveline runs true, timing events remain precise, and components wear predictably. Conversely, worn or damaged keys and pins trigger a cascade of problems: timing drift in cam or injection systems, reduced pump output, pulley misalignment, belt tracking issues, and abnormal vibration that propagates into bearings and seals. A fatigued WOODRUFF KEY can shear under a torque spike, while fretting in the hub/key interface leads to ovalized keyways and costly shaft or gear replacement.

Routine inspections should look for bright fretting marks, mushroomed key edges, burrs on keyway flanks, uneven hub seating, and axial play. Measuring key and keyway dimensions, validating fit, and replacing out-of-spec parts during scheduled overhauls protects critical assets. In marine service, where load cycles and ambient conditions fluctuate, these checks are essential to avoiding unplanned downtime and off-hire costs.

Advantages of OEM spare parts suitable for connecting elements and the WOODRUFF KEY

Using OEM spare parts suitable for connecting elements delivers consistent performance and predictable maintenance outcomes. For a WOODRUFF KEY OEM parts approach, dimensional fidelity (width, height, radius), controlled metallurgy, and repeatable hardness directly translate into stable torque transfer, accurate timing, and reduced fretting. Correct fillet radii and surface quality protect keyseats, while verified material certificates support safety and compliance goals.

For purchasers and technical managers, the benefits are tangible: fewer fitment issues during overhauls, shorter service windows, and lower lifecycle spend due to reduced collateral damage on shafts, hubs, and bearings. In high-output diesel and gas engines, small deviations in a key’s geometry can amplify into measurable efficiency losses; OEM spare parts suitable for connecting elements keep engines on their performance curve and extend the useful life of expensive rotating assemblies.

Specifying a WOODRUFF KEY for marine engine and diesel engine applications

When specifying a key, confirm the standard (e.g., DIN 6888), size code, shaft keyseat dimensions, hub keyway width and depth, and any environmental requirements such as anti-corrosion finish. Verify the drive type (taper vs. straight), required fit, and torque load case. For fleets, adopt a common specification across sister vessels to streamline inventory and minimize picking errors.

MOPA as a partner for OEM spare parts: connecting elements and WOODRUFF KEY

MOPA is an experienced, reliable partner for OEM spare parts in the connecting elements category. We supply WOODRUFF KEY OEM parts, pins, circlips, and related components for diesel and gas engines with a focus on speed, quality, and transaction security. Our team supports purchasers and superintendents with technical clarification, fast sourcing, and consolidated shipments—reducing downtime risk across marine engine and power-generation operations. With traceable supply and careful packaging suitable for harsh environments, MOPA helps keep critical assets running to plan.

Conclusion

Connecting elements—especially the WOODRUFF KEY—are fundamental to torque transmission, timing stability, and safe operation in diesel and marine engines. Selecting OEM spare parts suitable for connecting elements preserves performance, safeguards budgets through reduced downtime, and extends service life. MOPA provides the speed and quality you need to source these parts with confidence.