COOLER PLATE

COOLER PLATE and Coolers for Heavy‑Duty Engines

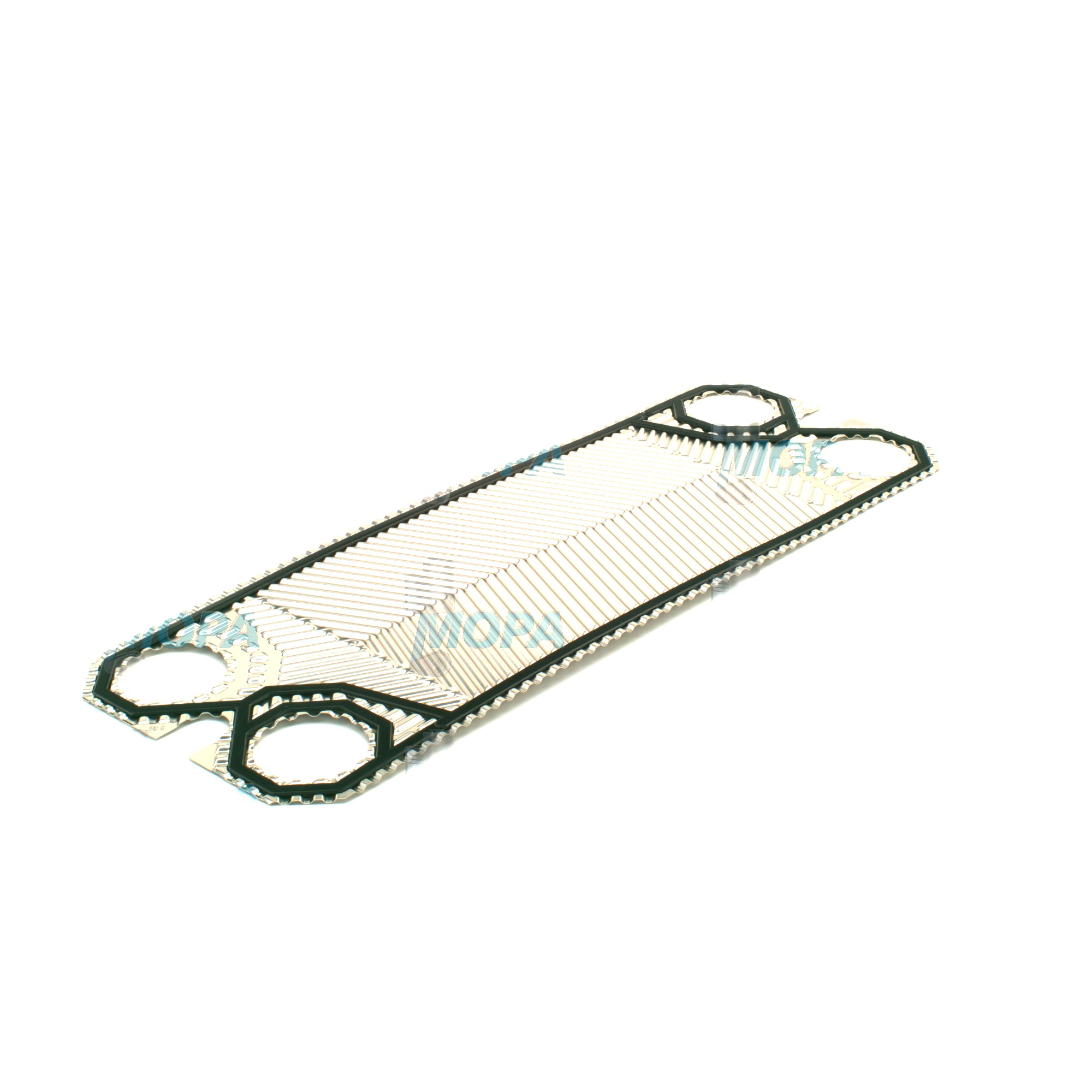

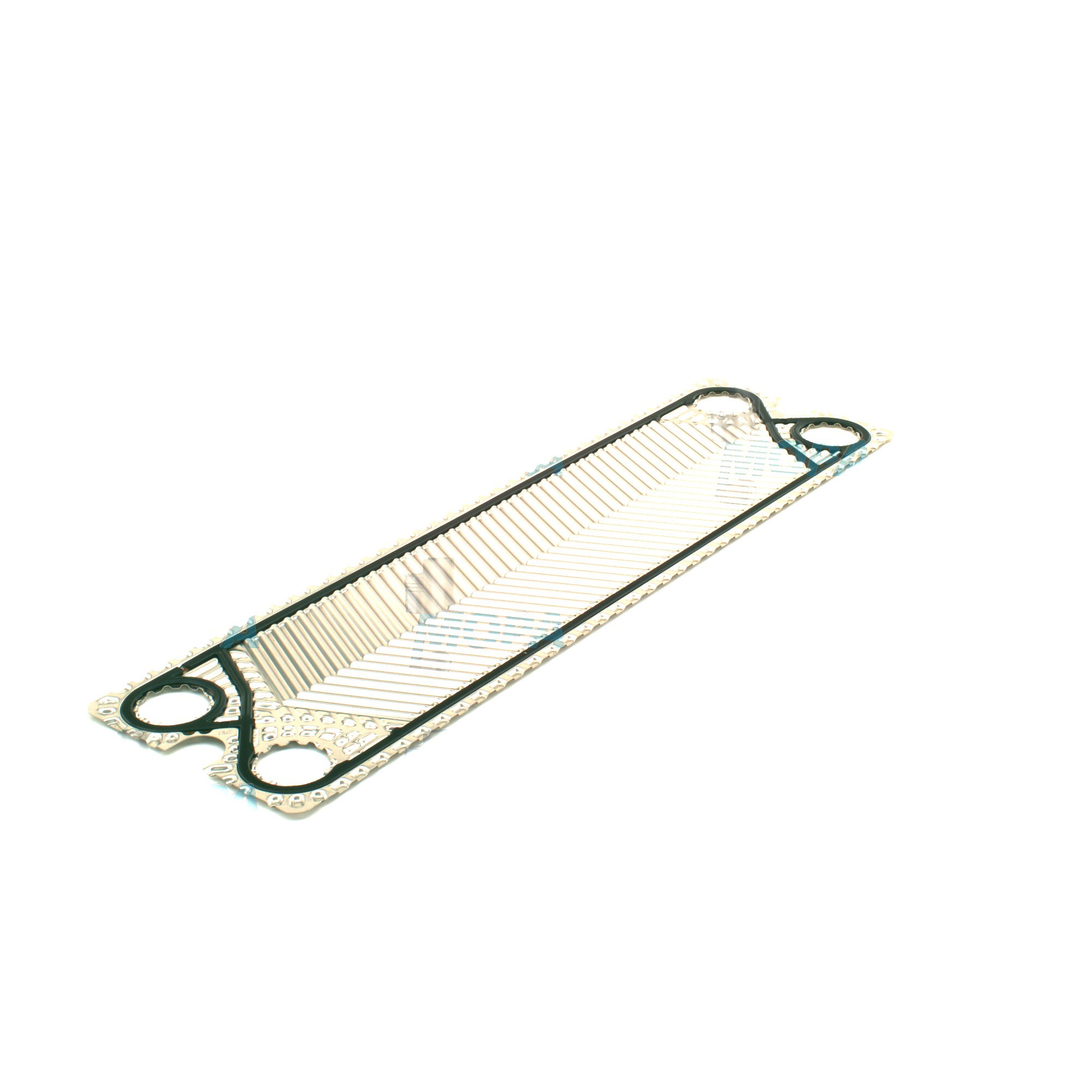

Coolers are critical heat-exchange components in propulsion and power‑generation systems. Whether installed as jacket‑water coolers, lube‑oil coolers, charge‑air coolers, or fuel coolers, they stabilize temperatures across core engine circuits and protect every major assembly from thermal stress. Within this category, the widely used COOLER PLATE design (gasketed or brazed plate heat exchanger) delivers high thermal efficiency in a compact footprint, making it ideal for confined engine rooms in ships and industrial plants. By efficiently transferring heat between process fluids and seawater or freshwater circuits, coolers sustain peak performance, emissions compliance, and safe operation.

For technical decision‑makers and shipowners, understanding how coolers work—and how to select the right COOLER PLATE set for a marine engine or a diesel engine—directly influences fuel economy, uptime, and lifecycle costs. Correct sizing, materials, and flow configuration prevent overheating, oil film breakdown, and charge‑air derating, while ensuring the engine reaches and maintains its designed load profile.

Technical function of coolers and COOLER PLATE assemblies in marine and diesel engine systems

Coolers remove heat from engine fluids and gases using conduction through metallic surfaces and convection to a cooling medium. In a COOLER PLATE unit, alternating corrugated plates create narrow channels for counter‑current flow. The chevron pattern induces turbulence at moderate Reynolds numbers, enhancing heat transfer coefficients while controlling pressure drop. Gasketed designs allow easy plate count adjustments; brazed versions provide compact, high‑pressure capability for clean circuits.

Typical circuits include jacket water to seawater (or central cooling water), lube oil to water, and charge air to water. Thermostatic valves and bypass lines regulate coolant temperature so that the engine warms quickly and then stabilizes at setpoint. Performance is measured by approach temperature, overall heat‑transfer coefficient (U‑value), and allowable differential pressure across both the process and cooling sides. Proper COOLER PLATE OEM parts selection preserves these design targets, preventing losses in thermal margin that can lead to alarms or derating.

Design variants and materials for COOLER PLATE coolers

Plate materials are chosen for corrosion resistance and strength: 316L stainless steel is common for freshwater; titanium and cupronickel are preferred for seawater exposure; high‑temperature applications may require upgraded gasket elastomers (e.g., NBR, EPDM, FKM) matched to oil, glycol, or fuel chemistry. Plate geometry—corrugation angle, depth, and pressing pattern—sets the trade‑off between heat transfer and pressure drop, while nozzle sizing and distribution zones support even flow across the plate pack.

- · High thermal efficiency in a compact footprint.

- · Scalable capacity by adding or removing plates.

- · Optimized turbulence for better fouling resistance.

- · Broad material options for seawater and aggressive media.

- · Precise temperature control for stable engine loads.

- · Serviceable designs for rapid cleaning and re‑gasketing.

- · Compatible with diesel engine and marine engine duty cycles.

- · Proven performance with validated OEM parts specifications.

Why coolers are critical to engine operation and service life

Thermal control underpins reliability. If a cooler is undersized, fouled, or incorrectly assembled, jacket‑water temperatures rise, accelerating liner wear, cylinder head stress, and cavitation risk. Elevated lube‑oil temperatures thin the viscosity film, reducing hydrodynamic separation at bearings and causing premature wear or seizure. In charge‑air circuits, insufficient cooling raises intake temperature, lowers air density, increases specific fuel consumption, and may push emissions beyond class or regulatory limits.

Cross‑contamination is another high‑impact failure mode: a plate leak can mix oil and water, leading to emulsification, corrosion, and rapid bearing distress. Excessive differential pressure may deform plates, unseat gaskets, and trigger bypass events. Routine inspection, differential‑pressure trending, and scheduled cleaning‑in‑place maintain the heat‑transfer surface in design condition. Selecting the correct COOLER PLATE configuration for a marine engine or diesel engine prevents these issues and protects long‑term asset value.

Advantages of OEM spare parts suitable for coolers and COOLER PLATE units

Using OEM spare parts suitable for this category sustains the engineered performance of the cooler as delivered by the engine builder. Dimensional accuracy of plates, quality of gasket compounds, and the exact corrugation geometry preserve the validated heat‑transfer curves and pressure‑drop characteristics. This translates into stable operating temperatures, consistent fuel efficiency, and fewer unplanned shutdowns.

From a budget perspective, correct OEM parts reduce total cost of ownership by extending service intervals, streamlining maintenance, and preventing secondary damage from thermal excursions. Material traceability and controlled manufacturing processes ensure compatibility with seawater, glycol mixes, lube oils, and fuels, supporting long service life in harsh environments. For safety, maintaining specified thermal margins reduces the risk of hotspots, exhaust temperature imbalance, and turbocharger stress.

MOPA: experienced partner for OEM spare parts for coolers and COOLER PLATE assemblies

MOPA supplies OEM spare parts for coolers—including COOLER PLATE packs, gaskets, cover plates, nozzles, and related components—across diesel and gas engine platforms. Customers value our speed of delivery, consistent quality, and secure transaction processes. We support marine engine and power‑plant operators with technical selection, documentation, and traceability, ensuring that each cooler component aligns with the engine builder’s specifications and the vessel’s duty profile.

With global logistics, rigorous supplier auditing, and application expertise, MOPA helps reduce downtime and risk when maintaining thermal systems. Whether you require a like‑for‑like plate set, a gasket kit matched to media and temperature, or advice on optimizing approach temperature, our team delivers dependable solutions.

Conclusion

Coolers—and especially the COOLER PLATE designs used on marine engine and diesel engine installations—are fundamental to performance, efficiency, and safety. Keeping these units to specification with OEM spare parts safeguards thermal margins, extends service life, and protects your maintenance budget. MOPA provides fast, reliable access to the right components so your engines stay within design temperature—voyage after voyage.

Precise Cooler Plate as a Spare Part for EnginesDiscover the cooler plate with the comparison number 0002031646, an excellent product that is ideally suited for cooling your engines. This cooler plate ensures that your engine remains efficient and powerful even under demanding conditions. Characteristic is the unique design, which meets all the requirements for functionality as an outstanding OEM spare part.Accurate Dimensions for High EfficiencyThe cooler plate weighs only 0.435 kg and offers optimally adjusted dimensions with a length and width of 65.9 cm each and a height of 2.2 cm. This OEM spare part is suitable for MTU engines of the MTU series and specifically supports the engine type compatible with 12V183TE94. Thanks to this precision, installation is effortless and ensures that the cooling processes of your engine operate optimally.

Premium Cooler Plate Suitable for MTU Engines of the Series 2000Experience the first-class cooler plate with the part number X00004917, an OEM replacement part specifically designed for use in engines suitable for MTU of the series 2000. This product is suitable for both the 16V2000 and 16V2000M90 models and ensures smooth operation. With comparatively compact dimensions of 76 cm in length, 76 cm in width, and 1 cm in height, along with a weight of only 0.42 kg, the cooler plate is an ideal choice for your engine applications.Reliable OEM Replacement Parts for Your NeedsThe quality and safety of OEM replacement parts are unmatched. This cooler plate, suitable for the manufacturer MTU, meets all high standards that you would expect from a professional replacement part. Rely on our product to optimize the performance of your engine and avoid unforeseen restrictions. Our cooler plate X00004917 is a proven choice when it comes to sustainably enhancing the efficiency and longevity of your engines.

Discover the Cooler Plate X00004918: Quality in Every DetailThe Cooler Plate with the reference number X00004918 is an essential product when it comes to the efficient cooling of your engines. Its outstanding design ensures that your engine operates optimally and does not overheat. As an OEM replacement part, it offers all the features and specifications you would expect from a manufacturer to support the longevity and reliability of your equipment.Developments: Suitable for MTU Engines 16V2000M90This Cooler Plate is suitable for MTU engines used in the 2000 series, such as the 16V2000M90. Weighing in at a clear 0.4 kg and with harmonious dimensions of 76 cm x 76 cm x 1 cm, the component can be easily installed. This construction maximizes the cooling forces, ensuring smooth and long-term operation of the engines, an indispensable quality for demanding applications.

OEM Spare Part: Cooler Plate for MTUDiscover the cooler plate suitable for MTU engines, a crucial OEM spare part that supports the functionality of your engines worldwide. With the comparison number 0002036946, this product is specifically designed for series 331 and 396. It is ideally suited for engine types 12V331TC92 and 12V396TE94. The plate measures 70.2 cm in length and width and 0.9 cm in height, weighing only 0.457 kg, which facilitates installation and ensures maximum operational capability.

Cooler plate with comparison number X00004575The cooler plate with the comparison number X00004575 is an essential OEM spare part that ensures optimal cooling in your machines. This product is suitable for the 2000 series of MTU engines. Whether you need one of the following engine types: compatible with 10V2000M93, 12V2000M93, or 8V2000M92, you can rely on the efficiency of this cooler plate. Weighing only 0.44 kg, this spare part offers excellent performance.

COOLER PLATE with the comparison number 12136812 suitable for MWM & Deutz engines

Cooler plate for Your Application NeedsDiscover the cooler plate with the comparison number 0001880446, a spare part designed for MTU engines. This product offers top-notch performance and durability required in demanding applications.

Discover the Cooler Plate with Comparison Number 0002034046The cooler plate with the comparison number 0002034046 is an essential OEM spare part. This cooler plate ensures that your engines, particularly the MTU engines, operate efficiently. It impresses not only with its functionality but also with the reliability that OEM spare parts provide. This solution is specifically designed for the engine type with the comparison number 0002034046.Perfect Cooling for MTU EnginesWeighing only 0.459 kg, the cooler plate is ideal for use in cooling applications. Its main function is to prevent overheating, thereby supporting the lifespan of your MTU engines. The product ensures that your engine remains powerful and efficiently cool, regardless of the conditions under which it operates.

Efficient Cooling Component for Motorized ApplicationsDiscover the cooler plate with the comparison number 5062030499, which ensures an ideal fit for MTU engines. This OEM replacement part delivers excellent performance tailored to the demands of marine and stationary applications. Rely on qualities based on many years of experience in the field of engine replacement parts.Powerful: The Cooler Plate Suitable for MTUThe cooler plate, compatible with various MTU engines, plays a crucial role in efficient cooling and maintaining engine performance. Our OEM replacement parts are characterized by close collaboration with manufacturers, which enhances durability and functionality. Trust in proven parts, especially suited for the 183 series—delivering the performance you need.

Quality That Convicts: Cooler Plate 0001880346Discover the cooler plate suitable for MTU engines with the comparison number 0001880346. This product ensures an excellent fit and is an essential OEM replacement part for your new or existing engines. Our cooler plates are ideal for tackling the challenges faced by diesel and gas engines.

COOLER PLATE with the comparison number X00004966 suitable for MTU engines

Cooler plate with type designation 5062030299Discover the cooler plate with the comparison number 5062030299, an innovative OEM replacement part specifically designed to meet the demands of your industry. This cooler plate is an essential product suitable for MTU engines of series 183 and optimizes the performance of the engines in marine and stationary applications.

Cooler Plate for Your MTU Engines Discover our cooler plate with the comparison number 5322030446, the perfect solution for your engines. This cooler plate is specifically designed to operate with high efficiency and provide optimal cooling for your drive systems. With dimensions of 71.5 cm in length and width, and a height of only 0.5 cm, it is ideally suited for compact installations and integration into various setups.Fit for MTU Engines The cooler plate is compatible with MTU engines, particularly the series 2000 with the engine types 10V2000M93, 12V2000M93, and 8V2000M92. Weighing only 0.45 kg, it offers a lightness that significantly simplifies handling during installation or replacement. Trust in the fit and precision of a product specifically developed to harmonize optimally with your engines.

Cooler Plate – OEM Spare Part in DetailDiscover the cooler plate with the comparison number 0002032846, a top-quality OEM spare part specifically designed for MTU engines. This product contributes to the optimal cooling of the engines and ensures reliable operation in demanding marine and stationary applications. Weighing only 0.505 kg, the cooler plate can be easily installed and handled.Advantages of OEM Spare PartsChoose OEM spare parts like our cooler plate to receive the best quality. Compared to alternative products, OEM parts are manufactured directly by the Original Equipment Manufacturer, which means they fit precisely according to the manufacturer's standards and support long-term performance tailored to MTU engines.

Cooler plate for optimal engine performanceDiscover the cooler plate with the comparison number 0002036846 – an essential product that reliably supports your MTU engines. This cooler plate has been precisely manufactured and is suitable for the renowned series 331 and 396. Based on the factors that influence the cooling performance of your diesel or gas engine, this plate significantly optimizes efficiency. With compact dimensions of 70.4 cm in length and width and 1.3 cm in height, it expertly meets the specific requirements of engines.Suitable for various MTU engine typesThe cooler plate is specifically compatible with engine types such as the 12V331TC92 and 12V396TE94. Weighing only 0.474 kg, replacement is straightforward and time-saving. By investing in the quality of this replacement part, you ensure the longevity of your engine. The use of top-grade materials ensures that your MTU engines operate optimally and deliver peak performance for an extended period.

COOLER PLATE with the comparison number 12136813 suitable for MWM & Deutz engines

### Product Description: Cooler Plate Compatible with MTU EnginesBest Protection with Our Cooler Plate Discover our cooler plate, which is marked with the comparison number 5062030399. This OEM spare part has been specially designed to enable efficient cooling of the engines. With its high standards, it is perfectly suited to harness the full potential of your machinery and ensure long operating times.Optimal Technology Compatible with MTU Engines The cooler plate is compatible with MTU engines of series 183. With compact dimensions of 75 cm in length, 75 cm in width, and a height of 0.5 cm, this cooler plate not only offers a space-saving solution but also combines functionality with efficiency. Weighing a pivotal 0.509 kg, it contributes to optimal usage.

High-Performance Cooler Plate for Marine UseDiscover the cooler plate with the comparison number 0002036946/87 – a reliable OEM spare part that is perfectly tailored to the requirements of engines in marine and stationary applications. This product is not only perfectly fitting but also impresses with precise manufacturing and selected materials. With a weight of 0.46 kg, this cooler plate is designed for the long-term operation of your engines.Focus on Engine Series and TypesThis cooler plate is suitable for MTU and is available in series 331 and 396. Additionally, the product is compatible with engine types such as 12V331TC92, 16V396TB94, and 8V396TE74L. The consistent level of OEM quality ensures that your engines can operate efficiently at all times.

COOLER PLATE with the comparison number 5062030899 suitable for MTU engines

Premium Cooler Plate for Efficient Cooling Discover the cooler plate from MOPA Motorparts, which meets the highest standards of quality and precision. This OEM spare part includes the comparison number 0002032046 and is suitable for MTU engines and their series 099. With this cooler plate, you ensure optimal cooling of your engines, which is essential for their efficiency and longevity.Precision Fit for Your Engines The cooler plate is designed to be specifically suitable for MTU engines, particularly for the series 099 and the specific engine type 6R099TA51. Weighing only 0.14 kg, the compact design helps make installation easier for the user while keeping operation stable.

Excellent Cooler Plate for Demanding ApplicationsDiscover the reliable cooler plate, comparison number 0002036846/87, suitable for MTU engines of series 331. This high-quality replacement part has been specially designed to ensure optimal protection and performance for your engine. Rely on OEM replacement parts that stand for a perfect fit and appealing quality.

Effective Cooling Solution: Cooler PlateDiscover our cooler plate (comparison number: 12276857), an essential OEM spare part that is perfectly suited for your technical requirements. With precise dimensions of 70.6 cm in length and width and a height of 0.8 cm, this product is ideally designed to ensure efficiency within the cooling system. Weighing only 0.438 kg, installation is easy and efficient.

Product Description – Plate Suitable for MWM & Deutz EnginesDiscover the Plate (comparison number: 12276854), which offers an excellent solution for all the requirements of your applications. This OEM replacement part impresses with its top-notch workmanship, optimizing the operation of your engines. With this Plate, you achieve long-lasting efficiency and reliability.Technical Details of the Plate and Its AdvantagesThis product is suitable for the 616 DIESEL series and the engine types TBD616 and TBD616-V8. Weighing 0.481 kg and with compact dimensions of 69.6 cm in length and width and a height of 0.9 cm, the Plate is very functional. The appropriate construction ensures smooth integration into existing systems and significantly contributes to the performance of your engines.

COOLER PLATE with the comparison number 0002033346 suitable for MTU engines