END PLATE insights for Coolers in marine and diesel engines

Coolers are critical heat-exchange components that stabilize temperatures across engine subsystems—charge air, jacket water, lube oil, fuel, and intercooler circuits. In heavy-duty applications such as propulsion sets and gensets, precisely engineered coolers maintain thermal balance, protect metals and lubricants from thermal stress, and preserve combustion efficiency. Whether installed as shell-and-tube units, plate heat exchangers, or integrated charge air coolers, their performance hinges on robust flow control and leak-tight sealing—functions strongly influenced by the END PLATE and its interfaces. Reliable coolers keep power output predictable, reduce fuel consumption, and extend the service life of high-value assets.

Technical function of Coolers and the END PLATE in engine systems

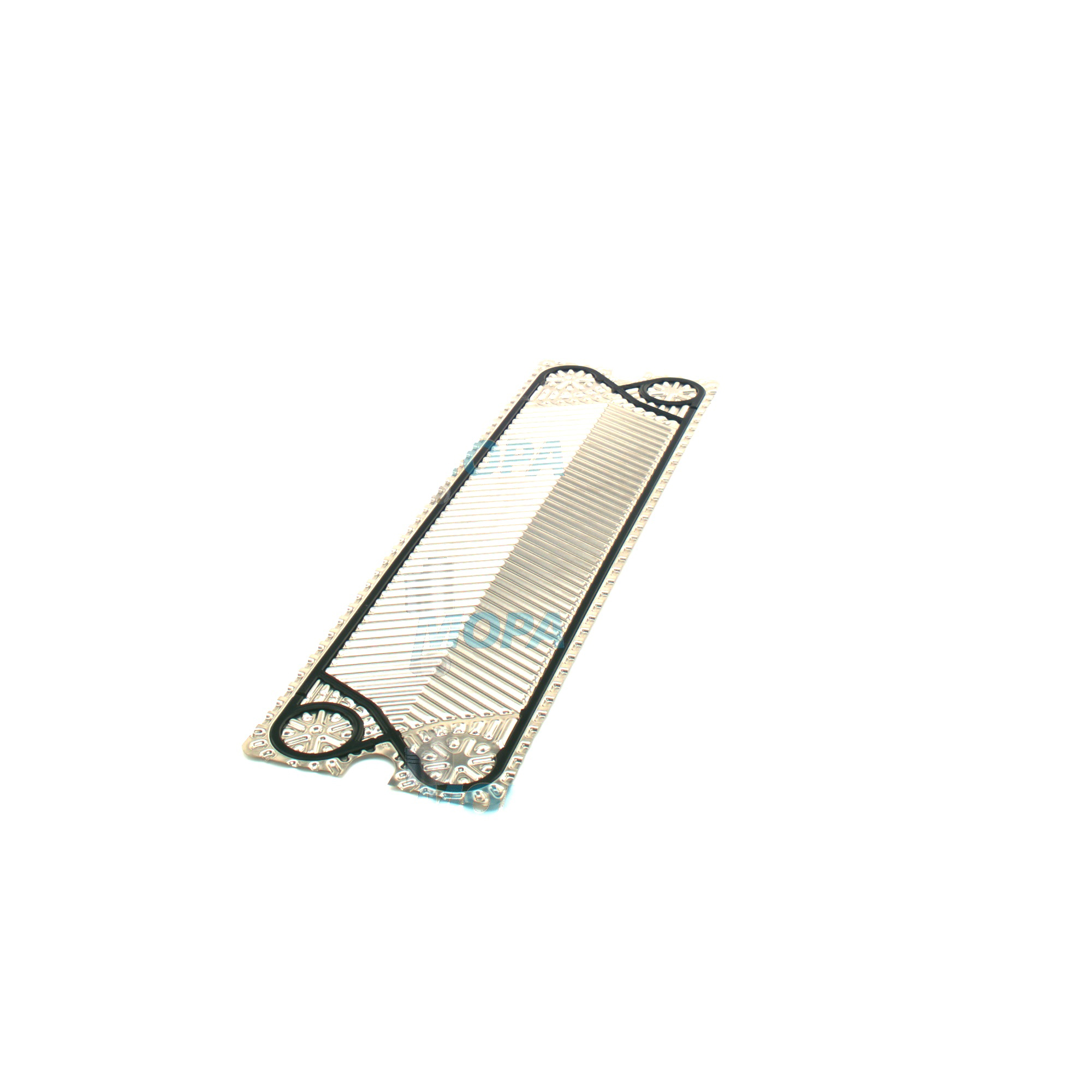

In an engine cooling circuit, a cooler transfers heat from a hot medium (e.g., jacket water, oil, charge air) to a colder medium (usually seawater, freshwater, or glycol mix). Thermal performance depends on surface area, flow regime, temperature differential, and material conductivity. The END PLATE closes the exchanger body, anchors the tube bundle (in shell-and-tube designs), controls inlet/outlet flow paths, and provides the sealing plane for gaskets or O-rings. In a marine engine installation, for example, the END PLATE marine engine cooler terminates the core and ensures that seawater or freshwater does not bypass the tube field, preserving the designed heat duty. In a diesel engine application, the END PLATE diesel engine charge air cooler helps maintain pressure integrity and airflow direction, safeguarding turbo efficiency and preventing thermal hotspots.

Material selection is equally important. Copper-nickel, stainless steel, duplex, and titanium are common choices matched to water chemistry and temperature. The END PLATE and tube sheet must resist galvanic corrosion and erosion from high-velocity fluids. Correct thickness, flatness, and surface finish help maintain uniform gasket compression, preventing micro-leaks that degrade efficiency and can cross-contaminate circuits (e.g., oil to water). Properly specified END PLATE OEM parts ensure dimensional compatibility with existing housings and retain the cooler’s certified pressure rating and thermal performance.

- · High thermal efficiency at stable pressure drop.

- · Corrosion-resistant materials for long service in seawater.

- · END PLATE geometry that secures tube bundles and seals reliably.

- · Optimized flow distribution to minimize hotspots and fouling.

- · Serviceable design for faster cleaning and re-gasketing.

- · Pressure- and leak-tested assemblies for operational safety.

- · Compatibility with class requirements and engine maker specs.

Importance for engine operation: why Coolers and the END PLATE matter

Thermal control underpins engine reliability. If coolers underperform, charge air becomes hotter and less dense, lowering power and increasing specific fuel consumption. Overheated jacket water accelerates liner wear and can trigger alarms or shutdowns. Oil that runs too hot loses viscosity, jeopardizing bearings and turbochargers. A compromised END PLATE, even with a minor sealing imperfection, may cause coolant leaks, oil dilution, or air ingress—each capable of escalating to unplanned downtime and expensive repairs.

Typical failure modes include gasket creep due to improper torque, warpage of the END PLATE from thermal cycling, localized corrosion at crevice points, and erosion near inlets where velocities peak. Fouling—biofouling from seawater or scaling from hard freshwater—raises thermal resistance, forces higher temperature deltas, and can push the engine out of its safe operating window. Routine inspection of the END PLATE sealing faces, replacement of fatigued fasteners, and pressure testing after service are essential to sustain cooler efficiency and engine health.

END PLATE diesel engine sealing and maintenance

In high-load diesel platforms, the END PLATE diesel engine interface must deliver repeatable compression of gaskets or O-rings across the entire perimeter. Clean, flat sealing faces and precise bolt loading prevent channeling and cold-flow of elastomers. For marine service, the END PLATE marine engine configuration often includes corrosion-resistant coatings, cathodic protection considerations, and drain/vent plugs to ease maintenance and reduce trapped air that can impair heat transfer.

Advantages of OEM spare parts suitable for Coolers and END PLATE assemblies

Choosing OEM spare parts for coolers preserves the efficiency and reliability that engines were designed to achieve. Tolerances, metallurgy, and surface finishes are aligned with the cooler’s thermal and pressure design, which keeps heat duty, pressure drop, and sealing performance within specification. This protects performance, safeguards reliability, supports budget control by reducing rework and premature replacements, and extends service life across maintenance cycles.

Replacement END PLATE OEM parts come with the correct port locations, fastener patterns, and sealing groove geometry—critical for reusing existing tube bundles and housings without modifications. Consistent materials mitigate galvanic risks and maintain structural integrity under cyclic thermal loads. For purchasers and technical stakeholders, this translates to predictable installation times, fewer leaks after commissioning, and stable engine KPIs (load response, fuel rate, and emissions conformity) over the long term.

MOPA as your partner for OEM spare parts Coolers and END PLATE solutions

MOPA supplies OEM spare parts for Coolers—shell-and-tube, plate-type, and charge air coolers—along with END PLATE components, tube bundles, gaskets, and fasteners for diesel and gas engines. Customers rely on MOPA for speed in sourcing, consistent quality, and transaction security. Our team cross-references engine and cooler data to identify precise parts, supports technical questions around materials and ratings, and coordinates fast shipping to minimize downtime. For shipowners, power plant operators, and industrial users, MOPA’s approach shortens lead times and reduces operational risk while keeping fleets and plants within planned maintenance windows.

Conclusion: Coolers and END PLATE OEM parts for lasting performance

Coolers safeguard engine efficiency and durability, and the END PLATE is central to sealing, flow control, and structural stability. Selecting OEM spare parts suitable for Coolers—especially the END PLATE—helps maintain design heat duty, prevent leaks, and protect budgets through dependable service life.

MOPA provides the speed, quality, and security needed to source the right cooler components for marine and diesel engines, keeping your equipment operating at peak performance.