FIRST PLATE Coolers for demanding diesel and marine engines

Coolers are critical heat exchangers that stabilize temperatures in combustion engines by transferring heat from liquids and gases to a secondary medium. In marine engines, power generation sets, and heavy-duty industrial drives, they regulate jacket water, lubricating oil, charge air, and sometimes fuel temperature—protecting components, stabilizing clearances, and sustaining optimal combustion. From compact plate heat exchangers to robust shell-and-tube units and finned charge air coolers, the right cooler safeguards both performance and service life.

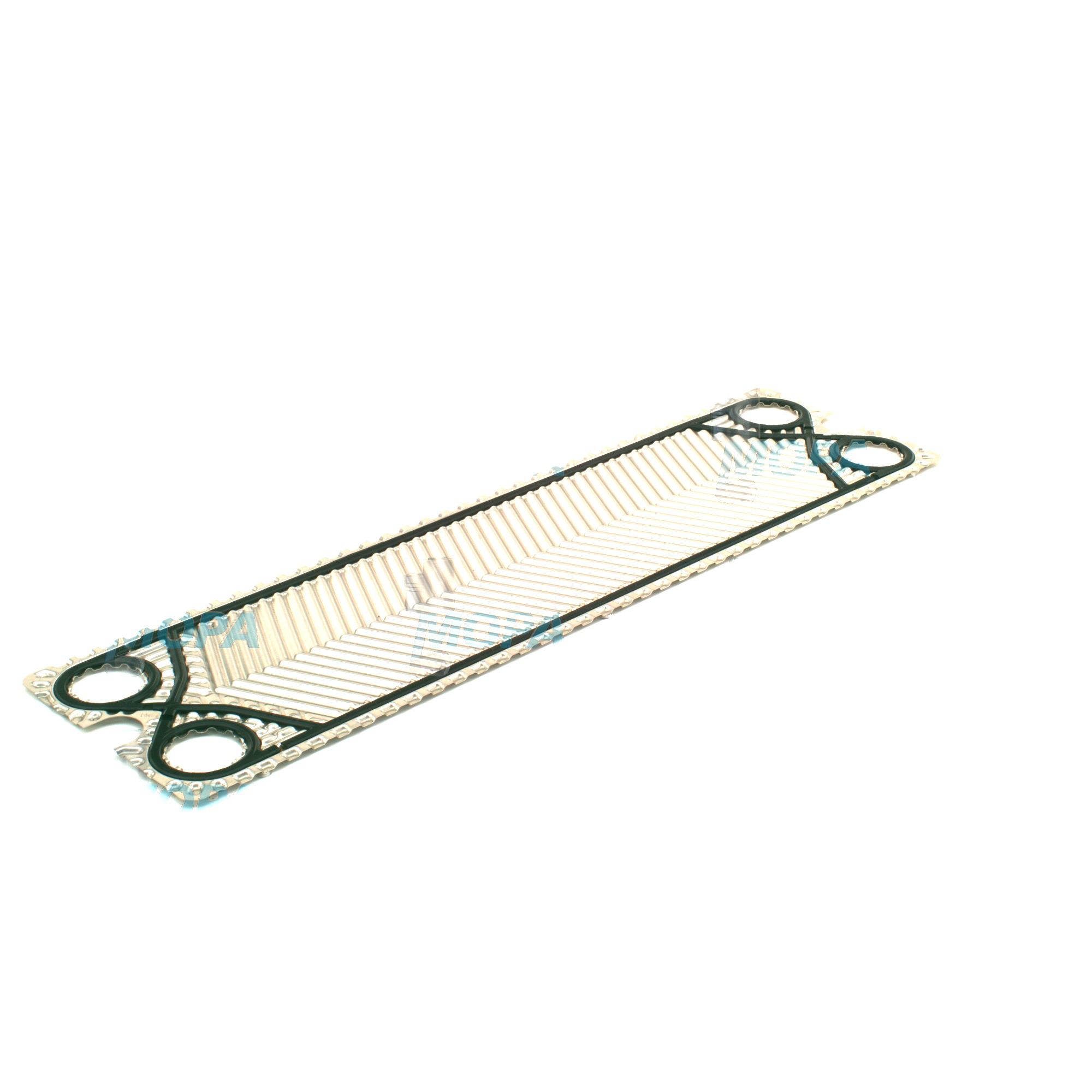

In plate heat exchanger assemblies, the FIRST PLATE defines the flow direction and turbulence pattern for subsequent plates. Specifying the correct FIRST PLATE marine engine configuration ensures designed approach temperatures, reliable sealing, and the pressure drop targets required by the engine cooling circuit. For diesel propulsion or gensets, correct cooler selection and maintenance translate into lower fuel consumption, stable emissions, and fewer unplanned shutdowns.

Technical function of Coolers in diesel and marine engines

Coolers manage heat rejection from multiple circuits. The jacket water cooler removes a large fraction of combustion heat—often 25–35% of the fuel’s energy—keeping cylinder liners, heads, and valve seats within a narrow temperature band. Lube oil coolers stabilize viscosity to maintain hydrodynamic films that protect bearings and turbocharger shafts. Charge air coolers (aftercoolers/intercoolers) reduce intake air temperatures from turbochargers, increasing air density, lowering peak combustion temperature, and improving power and NOx control. Fuel coolers protect injection equipment in high-return systems and prevent vapor lock.

Three primary designs dominate: plate heat exchangers (compact, high efficiency), shell-and-tube (robust, serviceable with brackish water), and bar-and-plate for air-to-liquid or air-to-air applications. In plate coolers, the FIRST PLATE diesel engine stack-up sets chevron orientation, port geometry, and sealing lanes. This ensures proper counterflow, optimized turbulence for fouling resistance, and a predictable approach temperature (often 5–10 K). Correct materials—CuNi 90/10 for seawater, titanium for aggressive media, stainless steel for closed loops—and elastomer selections (NBR, HNBR, FKM) keep corrosion and swelling in check. Proper sizing balances heat transfer against pressure loss, typically aiming for low Δp (e.g., 0.1–0.3 bar in coolant circuits) to protect pump margins.

- · Stable temperatures for cylinders, oil, and intake air.

- · High heat transfer efficiency with controlled pressure drop.

- · Materials matched to medium: CuNi, stainless steel, titanium, aluminum.

- · Configurable plate patterns and fin densities for performance targets.

- · Service-friendly: clean-in-place, pull-through bundles, replaceable plates.

- · Designed for fouling resistance and easy inspection.

- · Supports emissions compliance via precise thermal management.

- · Scalable from small auxiliaries to large-bore propulsion engines.

FIRST PLATE Coolers and their importance for engine operation

Thermal control underpins reliability. When a cooler deteriorates—due to scaling, biofouling, erosion, or gasket failure—temperatures drift. Overheated lube oil thins, eroding bearings and accelerating varnish formation. Insufficient charge air cooling raises intake temperatures, reducing air mass flow and forcing derates, higher fuel burn, and elevated exhaust temperatures that stress turbochargers and exhaust valves. Jacket water overtemperature can trigger alarms, detonation risk in gas engines, liner cavitation, and head gasket issues. Conversely, overcooling fosters condensation, sludge, and acid formation. Maintaining the correct cooler configuration—including the FIRST PLATE marine engine flow pattern—preserves the design heat balance, protects components, and sustains output across seasons and load profiles.

Advantages of OEM spare parts suitable for Coolers

Using OEM spare parts suitable for coolers preserves the engineered thermal performance of the system. Plate geometry, corrugation depth, and port design are calibrated to hit specific heat duties and flow distribution; mismatches can disrupt turbulence, reduce effectiveness, or raise pressure drops. Gaskets must match compound, hardness, and profile to resist the coolant or seawater chemistry and maintain clamping force over time. Tube bundles, headers, and fin blocks should replicate metallurgy and fin density to avoid galvanic issues and performance drift.

With FIRST PLATE OEM parts and matched components across the cooler, purchasing teams secure predictable outcomes: consistent approach temperatures, stable Δp, and correct bypass behavior. This leads to fewer rework cycles after overhauls, reduced downtime, and a lower total cost of ownership. Documentation, traceability, and dimensional consistency accelerate maintenance, while correct anode specifications and coating systems protect against corrosion in brackish or seawater service. For operators managing fleets, harmonized parts across sister vessels simplify inventory and reduce procurement complexity—without compromising heat load coverage or class compliance.

MOPA: your partner for OEM spare parts for Coolers

MOPA is an experienced, reliable partner for OEM spare parts for Coolers across diesel and gas engines. The team prioritizes speed, quality, and security in international trade—supporting urgent dockings and planned overhauls with short lead times, careful packing, and consistent documentation. Technical experts align plate packs, tube bundles, gaskets, and anodes to engine serial numbers and cooler model codes, ensuring the correct FIRST PLATE orientation and complete bill of materials for jacket water, lube oil, and charge air systems.

Whether you operate a deep-sea vessel, OSV, ferry, or power plant, MOPA supports you with sourcing, cross-references, and logistics that keep assets online. From corrosion-resistant materials to upgraded gasket compounds for challenging media, the focus is on dependable fit, thermal performance, and transactional security—and on minimizing downtime for shipowners and power producers alike.

FIRST PLATE Coolers in marine engine and power generation applications

Across propulsion, auxiliary gensets, and CHP units, correct cooler configuration determines efficiency and emissions stability. Matching the FIRST PLATE to the intended flow regime helps maintain clean heat surfaces, limits fouling, and sustains heat balance under varying seawater temperatures and loads. Operators benefit from consistent SFOC, more stable EGTs, and longer intervals between cleaning—key advantages for vessels on tight schedules and plants with firm dispatch commitments.

Conclusion: Coolers and OEM spare parts suitable for Coolers

Coolers are central to engine health, shaping power output, fuel efficiency, and component longevity by controlling temperatures in vital circuits. Accurate configuration—including the correct FIRST PLATE and materials—ensures reliable heat transfer and operational stability.

Choosing OEM spare parts suitable for Coolers preserves design performance, reduces maintenance risk, and optimizes lifecycle costs. With MOPA as your partner, you gain fast, secure access to quality components for diesel and gas engine cooling systems.