OIL COOLER COVER for Coolers in Marine and Diesel Engines

Coolers are critical heat-exchange components that keep key engine media—lubricating oil, jacket water, charge air, and sometimes fuel—within their specified temperature range. In medium- and high-speed engines, the cooler family includes shell-and-tube units, plate heat exchangers, and stacked-plate modules designed for continuous operation under high thermal loads. Within this system, the OIL COOLER COVER is a precision interface that closes the cooler housing, seals channels, and directs flow to maintain stable temperatures and reliable lubrication.

For shipowners, operators, and plant managers, properly specified coolers make the difference between smooth uptime and costly downtime. The cooler’s job is not only to shed heat, but to preserve the viscosity of the oil film that protects bearings, pistons, and turbochargers. When configured correctly—using the right cooler type, material, and an accurately machined OIL COOLER COVER marine engine assembly—engines run at optimal efficiency, emissions remain controlled, and component lifetimes extend to plan.

Technical function of Coolers and the OIL COOLER COVER in engine systems

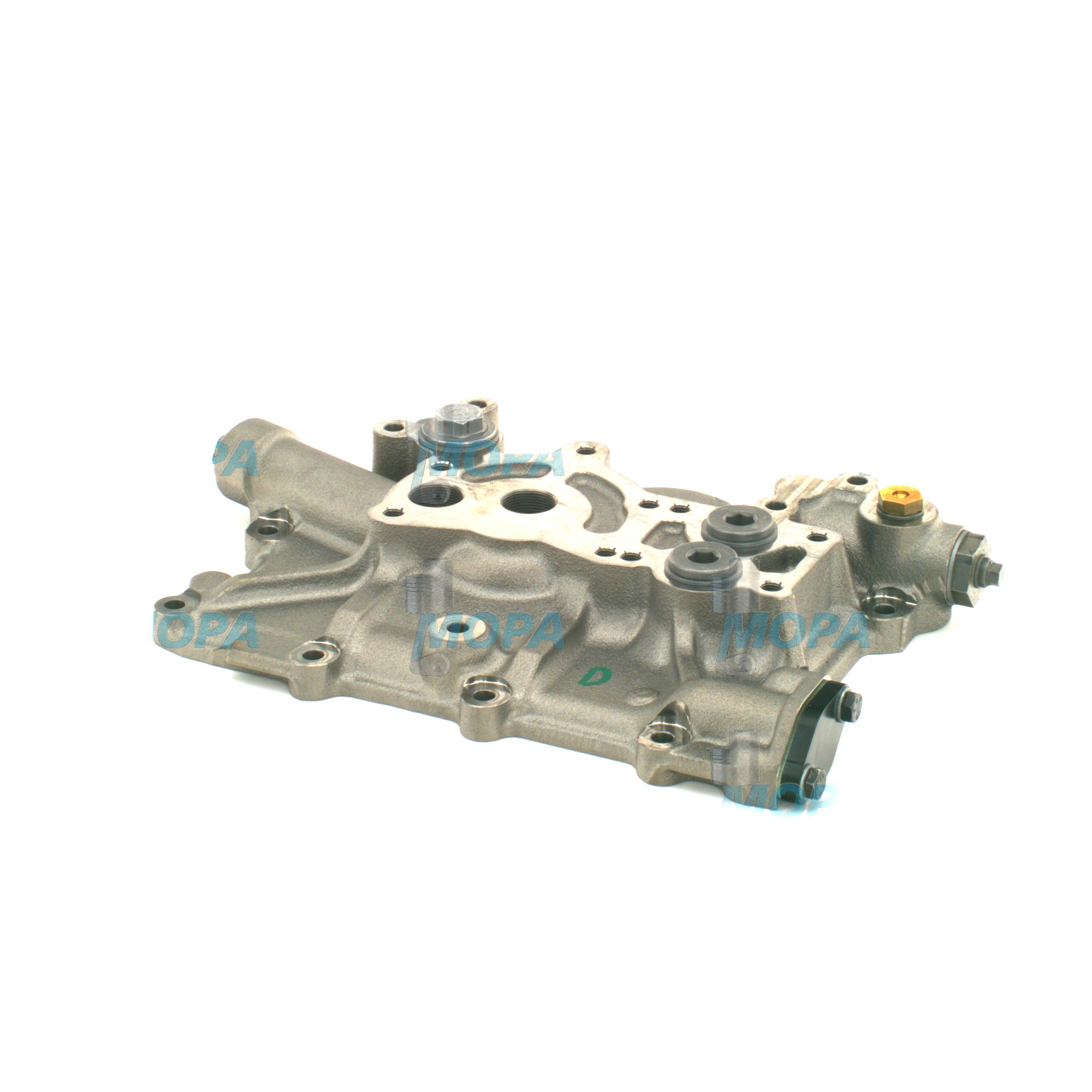

Coolers transfer heat from hot media to a colder medium—often seawater via a separate circuit or a closed freshwater loop. In an oil cooler, hot lube oil flows through plates or tubes while coolant passes on the opposite side. Thermal gradients move heat away from the oil, stabilizing operating temperature. The OIL COOLER COVER diesel engine component is the precision lid and flow director of this assembly: it defines inlets and outlets, controls distribution across the core, and provides sealing surfaces that prevent internal bypass or cross-contamination.

Beyond simple closure, the cover typically integrates galleries, sensor ports, and sometimes thermostatic bypass passages. Its flatness, surface finish, and geometry ensure uniform clamping of gaskets or O-rings, which is essential for maintaining design differential pressures. As loads increase, the integrity of the OIL COOLER COVER OEM parts and the cooler core keeps oil viscosity stable, reduces thermal stress on rotating groups, and supports consistent bearing clearances.

- · Stable oil temperature for reliable hydrodynamic film.

- · Optimized flow distribution via precisely machined cover channels.

- · Reduced coking and varnish by preventing hot spots.

- · Minimal pressure drop at design throughput for efficiency.

- · Secure sealing to avoid oil–coolant mixing.

- · Materials tailored to marine engine duty (e.g., CuNi, stainless steel).

Charge air and jacket water coolers follow the same heat-exchange principle. Their performance affects combustion quality, NOx control, and thermal loading of cylinder components. The reliability of the oil cooler—anchored by a correctly specified cover—often determines the overall thermal balance of the engine.

Importance of Coolers and the OIL COOLER COVER for engine operation

Thermal control is foundational to engine reliability. If coolers underperform or the OIL COOLER COVER loses sealing due to wear, warpage, or incorrect torque, oil temperatures rise and viscosity falls. The resulting thin oil film accelerates bearing wear, increases friction losses, and elevates oxidation rates. In severe cases, cross-leakage between oil and coolant circuits leads to emulsified oil, corrosion, and catastrophic bearing damage.

Typical failure mechanisms include tube bundle fouling, seawater-side scaling, erosion-corrosion at high-velocity inlets, gasket creep, and pitting around fasteners on the cover. Warning signs are high oil temperature alarms, rising differential pressure across the cooler, and unexplained oil level changes. Addressing these at the component level—especially the sealing and geometry of the OIL COOLER COVER marine engine assembly—prevents derating, unplanned stops, and costly overhauls.

Operational risks when Coolers or the OIL COOLER COVER are out of spec

Unchecked temperature excursions can drive piston scuffing, turbocharger distress, and accelerated degradation of elastomers. Oil–coolant mixing contaminates both circuits, undermining corrosion inhibitors and leading to widespread system cleaning and bearing replacement. Precision in the cover’s mating surfaces and the correctness of its ports and galleries are therefore central to long-term engine health.

Advantages of OEM spare parts suitable for Coolers and OIL COOLER COVER assemblies

Using OEM spare parts for coolers—and specifically for the OIL COOLER COVER diesel engine interface—preserves engineered tolerances, metallurgy, and surface finishes. Correct alloy selection (e.g., CuNi 90/10 or 70/30 on seawater sides, high-grade stainless on oil sides) resists galvanic attack. Verified flatness and surface roughness maintain seal integrity, while the right gasket compounds (NBR, FKM) match fluid chemistry and temperature.

With OIL COOLER COVER OEM parts, you benefit from validated flow geometry that ensures design pressure drops and heat-transfer coefficients. Parts fit first time, reducing installation hours and rework. Consistency in dimensions safeguards bearing temperature margins and supports predictable maintenance intervals—key for budgeting and lifecycle planning.

In short, OEM spare parts suitable for coolers deliver stable performance, dependable reliability, controlled total cost of ownership, and extended service life without compromising the engine’s thermal balance.

MOPA as a partner for OEM spare parts Coolers and OIL COOLER COVER

MOPA is a trusted partner for OEM spare parts in the Coolers category, including complete oil cooler units and the OIL COOLER COVER interfaces for diesel and gas engines. We focus on speed, quality, and security in procurement and delivery: fast order processing, proven supplier networks, and meticulous documentation ensure you receive the right parts on time.

Our team supports part identification from engine serials and drawings, cross-references legacy numbers, and provides material and test records where applicable. From corrosion-resistant cooler bundles to precision-machined covers, we supply components that align with engine maker specifications. Packaging, preservation, and global logistics are optimized for marine and power segments, minimizing handling risk and delivery time.

Conclusion on Coolers and the OIL COOLER COVER OEM parts

Coolers safeguard engine temperature control, and the OIL COOLER COVER is the small but decisive component that makes their performance airtight. Selecting OEM spare parts suitable for this category secures fit, sealing, and flow accuracy—directly supporting engine efficiency, reliability, and service life.

Partner with MOPA to source OEM spare parts for Coolers and the OIL COOLER COVER with the speed and quality your operation demands.