THERMAL ACTUATOR insights for Coolers in high-performance engines

Coolers are critical heat exchangers that stabilize the thermal balance of engines. Whether in a compact genset or a large marine propulsion system, they transfer heat from engine fluids—such as jacket water, charge air, fuel, or lube oil—to a secondary medium (seawater, freshwater, or ambient air). By keeping temperatures within tight limits, coolers protect components from thermal stress, safeguard lubricating films, and sustain optimal combustion. As a result, they are among the most important components for durability, efficiency, and safety in both diesel and gas engines.

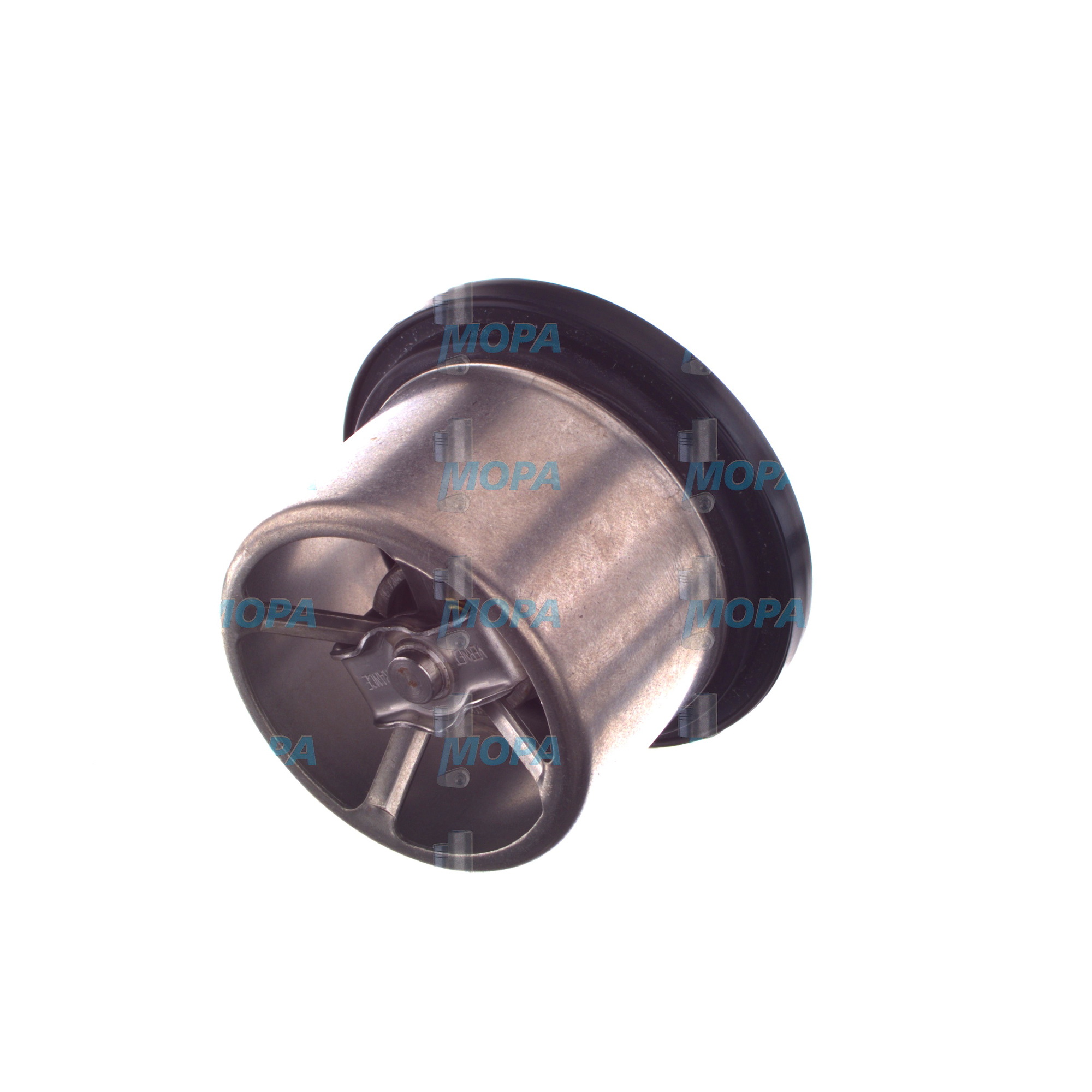

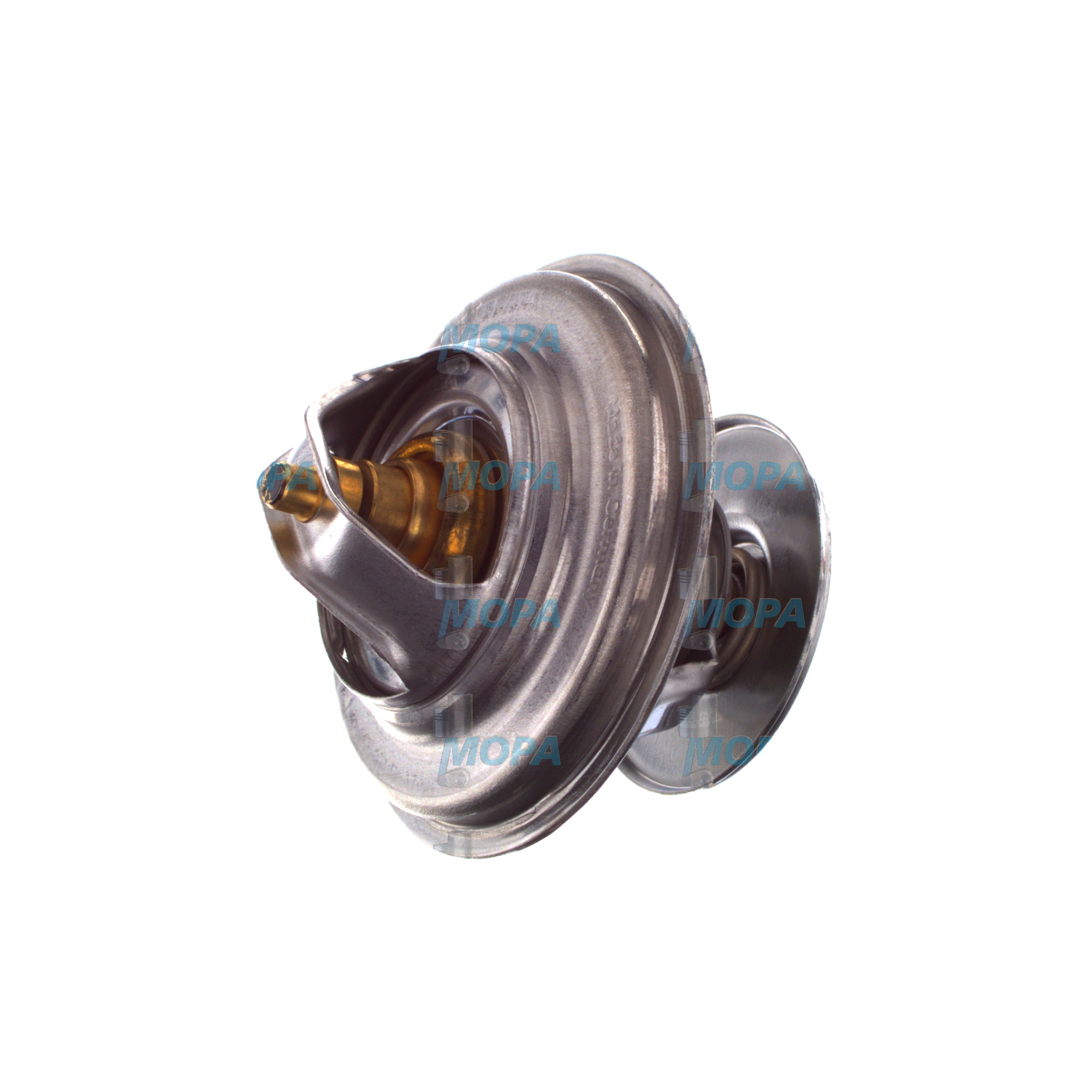

In practice, engine coolers appear in several forms: shell-and-tube coolers for jacket water and lube oil, plate heat exchangers for compact, high-efficiency installations, and charge air coolers (intercoolers/aftercoolers) that densify intake air to lift power density. On modern control loops, the THERMAL ACTUATOR often works in tandem with thermostatic valves, bypass circuits, and shutters to modulate coolant flow precisely—especially in a marine engine where variable load profiles and seawater temperatures demand responsive thermal management.

Technical function: how Coolers and the THERMAL ACTUATOR support diesel engine performance

Coolers operate by maximizing heat transfer across well-engineered surfaces while minimizing pressure loss and cross-contamination risk. In a diesel engine, the jacket water cooler extracts heat from cylinder liners and heads to prevent hot spots and cavitation damage. The lube oil cooler stabilizes viscosity, ensuring hydrodynamic lubrication across bearings and cam surfaces. The charge air cooler lowers intake air temperature downstream of the turbocharger to increase oxygen density, improving combustion efficiency, power output, and emissions control.

Control is equally important. A THERMAL ACTUATOR diesel engine solution—integrated with thermostats and bypass valves—modulates coolant flow based on real-time temperature, keeping components within a narrow operating window during start-up, transient load changes, and heavy-duty operation. In a THERMAL ACTUATOR marine engine configuration, this precision reduces thermal shock when cold seawater is introduced, mitigating stress on coolers and preventing condensation in charge air systems. When specified as THERMAL ACTUATOR OEM parts, the actuation hardware aligns with heat exchanger characteristics (materials, geometry, flow coefficients) to deliver stable setpoints and balanced flows.

- · High heat transfer efficiency under variable loads.

- · Stable operating temperatures for peak combustion quality.

- · Protection against thermal shock and cavitation.

- · Lower NOx and particulate emissions via charge air cooling.

- · Controlled viscosity and film strength through oil cooling.

- · Reduced fuel consumption and extended component life.

- · Efficient integration with THERMAL ACTUATOR control loops.

Importance for engine operation: why Coolers are mission-critical

Coolers directly influence reliability and service life. Overheating accelerates oxidation of lubricants, weakens gasket materials, and can warp heads or liners. Undercooling is equally damaging, fostering incomplete combustion, acid formation, and moisture condensation—especially in charge air systems. Fouling (biofouling on seawater sides, scaling, soot on charge air fins) cuts heat transfer and increases pressure drop, while corrosion and erosion can lead to tube leaks and cross-contamination between fluids. Any of these issues can produce rapid performance decay, elevated fuel burn, or catastrophic damage.

Properly specified and maintained coolers maintain thermal margins that protect bearings, pistons, turbochargers, and aftertreatment equipment. With a tuned THERMAL ACTUATOR control strategy, the cooling circuit adapts to load steps without overcooling or overshooting, minimizing thermal cycling and extending the interval between overhauls. For vessels and power plants, this translates into higher availability, predictable maintenance planning, and lower lifecycle cost.

Advantages of OEM spare parts suitable for Coolers

Using OEM spare parts suitable for coolers preserves the engineered performance of heat exchangers and their control loops. Heat transfer depends on precise geometries, surface treatments, gasket compounds, and metallurgy. Mismatches can alter flow distribution, reduce effectiveness, or introduce galvanic risks in seawater service. With OEM spare parts, you align plates, tubes, headers, seals, and fasteners with the exact thermal and mechanical requirements of the engine platform.

In addition, THERMAL ACTUATOR OEM parts for the cooling circuit ensure the actuation characteristics—stroke, hysteresis, response time—match valve and cooler dynamics. This prevents hunting in temperature control, reduces bypass losses, and preserves thermal stability across ambient and load variations.

Key benefits of choosing OEM spare parts for Coolers and THERMAL ACTUATOR systems

- · Consistent heat transfer performance and pressure drop.

- · Material compatibility for seawater, glycol, or oil service.

- · Proper fit, sealing, and torque load distribution.

- · Predictable control response with THERMAL ACTUATOR components.

- · Reduced downtime due to straightforward installation.

- · Better fuel efficiency and extended service intervals.

- · Reliable documentation and parts traceability for audits.

MOPA: your partner for OEM spare parts suitable for Coolers

MOPA supplies OEM spare parts suitable for coolers used in diesel and gas engines, supporting shipowners, power producers, and industrial operators worldwide. As a reliable partner, MOPA emphasizes speed in quotation, order handling, and logistics to minimize downtime. Quality is embedded through vetted sourcing, technical validation, and compatibility checks for specific engine models and cooling configurations. Security in trade is ensured via transparent documentation, parts traceability, and careful handling throughout the supply chain.

Whether you need jacket water cooler elements, charge air cooler cores, lube oil cooler bundles, gaskets and seals, or associated THERMAL ACTUATOR OEM parts for precise temperature control, MOPA provides technically correct solutions that match your operational profile and maintenance plan.

Conclusion

Coolers are indispensable for protecting engines, sustaining efficiency, and ensuring safe, reliable operation under real-world loads. Integrated with a properly matched THERMAL ACTUATOR and OEM spare parts suitable for coolers, the entire thermal management system delivers stable temperatures, lower fuel consumption, and longer component life. Partnering with MOPA helps you secure the right components quickly and confidently, keeping your diesel and gas engines operating at their best.