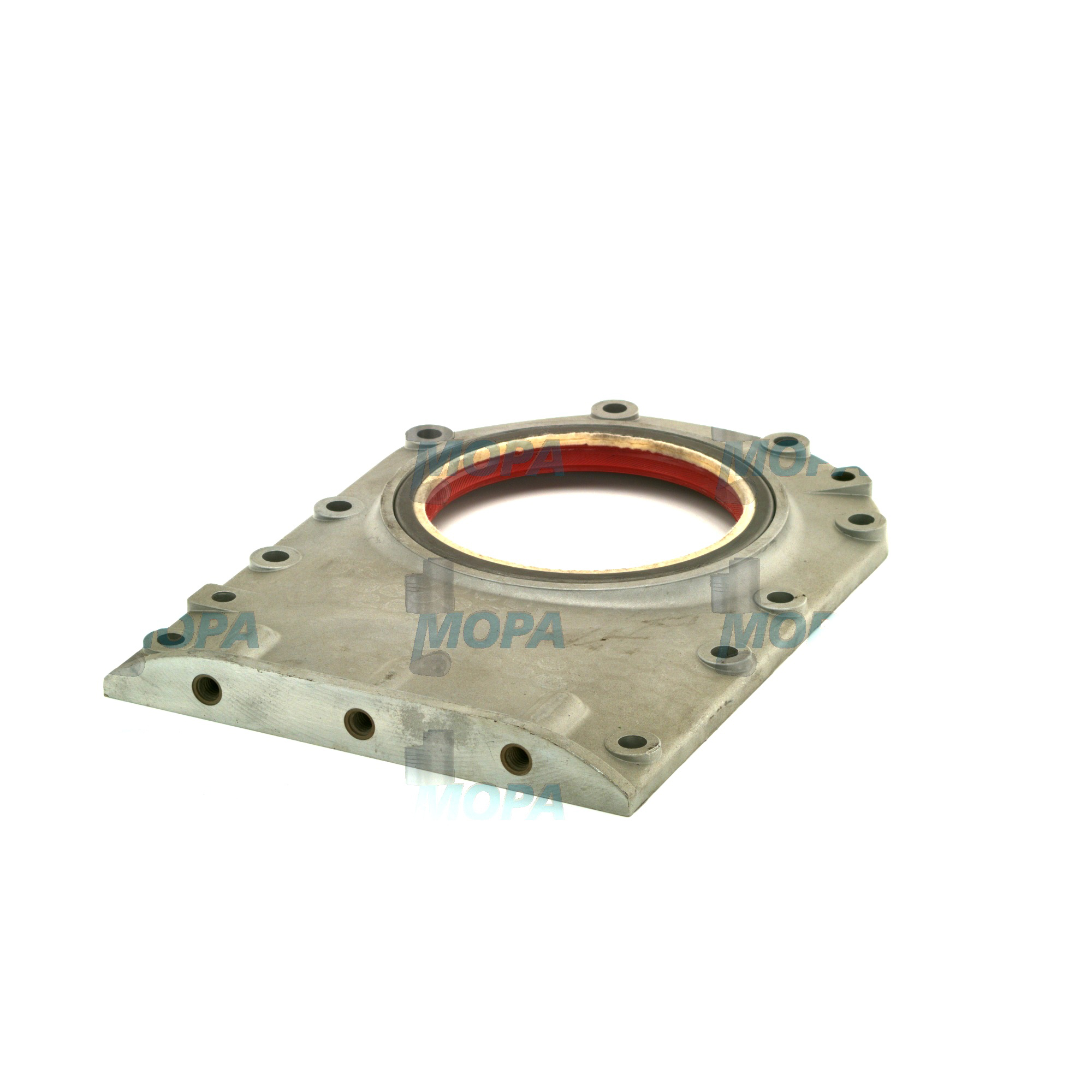

CRANKCASE END COVER insights for Crankcase parts in diesel and marine engines

Crankcase parts form the structural and sealing backbone of any reciprocating engine. This article category covers components that enclose, support, and protect the lower engine architecture: from the bedplate and bearing caps to covers, doors, seals, and ventilation hardware. These elements safeguard the crankshaft and main bearings, manage lubrication and blow-by gases, and keep contaminants out of the oil circuit. In heavy-duty diesel and marine engine applications, robust crankcase parts sustain high cyclic loads, thermal gradients, and torsional vibrations while maintaining dimensional stability and tight sealing performance.

Among these components, the CRANKCASE END COVER closes the axial end of the crankcase, aligning with the block and bedplate to maintain crankshaft concentricity, seal oil passages, and provide access for inspection or service. Whether in a high-speed genset diesel engine or a slow-speed marine engine, well-specified crankcase parts prevent oil leaks, pressure imbalances, and structural deflection that can escalate into bearing distress and unplanned downtime.

Technical function: Crankcase parts and the CRANKCASE END COVER in a diesel or marine engine

Crankcase parts stabilize the lower engine assembly, keep lubrication where it belongs, and control the internal environment. The CRANKCASE END COVER for a marine engine or industrial diesel engine completes the crankcase envelope. It interfaces with dowel pins for positional repeatability, carries sealing elements (gaskets or O-rings), and often integrates ports for breathers, relief devices, or condition-monitoring sensors. By closing off the axial end, it sustains crankcase rigidity, preserves oil mist containment, and maintains the correct vacuum or slight overpressure set by the ventilation system.

Functionally, the end cover and associated crankcase parts deliver: accurate main bearing housing geometry; consistent oil gallery sealing; resistance to vibration-induced loosening via defined bolt torque and tightening sequences; and thermal compatibility with the block to avoid warpage. In engines using split main bearings, the crankcase and covers must hold tight alignment tolerances to prevent edge loading, oil film collapse, and bearing temperature spikes. In safety-critical installations, correctly specified CRANKCASE END COVER OEM parts also support the integration of flame arrestors or relief features defined by engine maker standards.

- · Maintains crankshaft alignment and bearing concentricity.

- · Provides reliable oil and gas sealing at the crankcase boundary.

- · Supports vibration control and structural stiffness under load.

- · Interfaces with breathers, sensors, and inspection ports.

- · Withstands thermal cycles and prevents deformation.

- · Enables safe, clean service access without contaminating the crankcase.

Materials typically include high-grade cast iron or ductile iron for damping and stiffness, with precision-machined sealing faces and groove geometries for O-rings. Surface finishes are controlled (e.g., low Ra values) to stabilize gasket compression and reduce weep paths. Fasteners are specified for preload retention, and anti-corrosion coatings protect mating surfaces in salty or humid marine environments. For large-frame engines, end covers may integrate lifting eyes, alignment bosses, and inspection doors to simplify maintenance without disturbing primary seals.

Importance for engine operation and service life

Because crankcase parts define the lower engine geometry, any loss of integrity quickly impacts performance and reliability. Worn or distorted covers, damaged sealing grooves, or incorrect fastener preload can lead to persistent oil leaks, contamination ingress, and crankcase pressure deviation. These conditions elevate bearing wear rates, encourage varnish formation, and impair oil aeration control. In a diesel engine exposed to high torsional loads, micro-misalignment caused by compromised crankcase parts amplifies vibration and accelerates fatigue in bearings, couplings, and gear trains.

Poor crankcase breathing due to clogged passages or warped cover interfaces can elevate internal pressure, forcing oil past seals, increasing oil consumption, and elevating fire risk from oil mist. On marine engine installations, salt-laden air can accelerate corrosion at sealing faces if materials or coatings are not correct. Over time, these issues translate into increased operating cost, unplanned stoppages, and shortened overhaul intervals. Maintaining the CRANKCASE END COVER and related crankcase parts in specification preserves oil integrity, stabilizes thermal behavior, and protects the powertrain from progressive damage.

Advantages of OEM spare parts suitable for Crankcase parts

Specifying OEM spare parts suitable for crankcase parts ensures dimensional accuracy, metallurgy, and surface treatments match the engine maker’s design intent. This is particularly critical for the CRANKCASE END COVER OEM parts set, where even minor deviations in flatness, bore positioning, or gasket groove depth can compromise sealing and bearing alignment. With OEM parts, bolt patterns, dowel fits, and sealing interfaces match the block precisely, allowing faster installation and reduced rework during scheduled maintenance.

From a lifecycle perspective, correctly matched components maintain oil cleanliness targets, sustain bearing load distribution, and support vibration limits that protect couplings and foundations. The result is predictable service intervals and fewer secondary failures. Budget-wise, the upfront part cost is offset by lower leakage remediation, reduced oil consumption, and minimized downtime during dry-dock or outage windows. For fleets and power plants, standardized OEM specifications streamline spares management and help maintain compliance with class or site standards.

MOPA as a partner for OEM spare parts for Crankcase parts

MOPA supplies OEM spare parts suitable for Crankcase parts across leading diesel and gas engine platforms. Customers rely on our technical insight to identify the correct CRANKCASE END COVER for a marine engine, land-based generator, or industrial drive. We prioritize speed of supply through optimized logistics and a curated stock profile, enabling rapid turnarounds that protect production schedules and voyage plans.

CRANKCASE END COVER OEM parts: speed, quality, and security

MOPA’s processes emphasize traceable sourcing, documentation, and quality checks that align with engine maker specifications. Our team supports you with parts identification by serial/build list, guidance on gasket and fastener sets, and best practices for installation (torque patterns, surface prep, sealant selection). The result is secure transactions, consistent quality, and reduced risk during overhaul events—key factors for shipowners, operators, and procurement teams managing mission-critical assets.

Conclusion: CRANKCASE END COVER and Crankcase parts

Crankcase parts, including the CRANKCASE END COVER, are fundamental to engine integrity, sealing, and bearing alignment. Keeping these components in specification protects performance, fuel efficiency, and safety across diesel and marine engine applications.

Choosing OEM spare parts suitable for crankcase parts delivers the fit, materials, and tolerances required for long service life and dependable uptime. With MOPA as your partner, you gain fast, secure access to the right components—so your engines run stronger, cleaner, and longer.