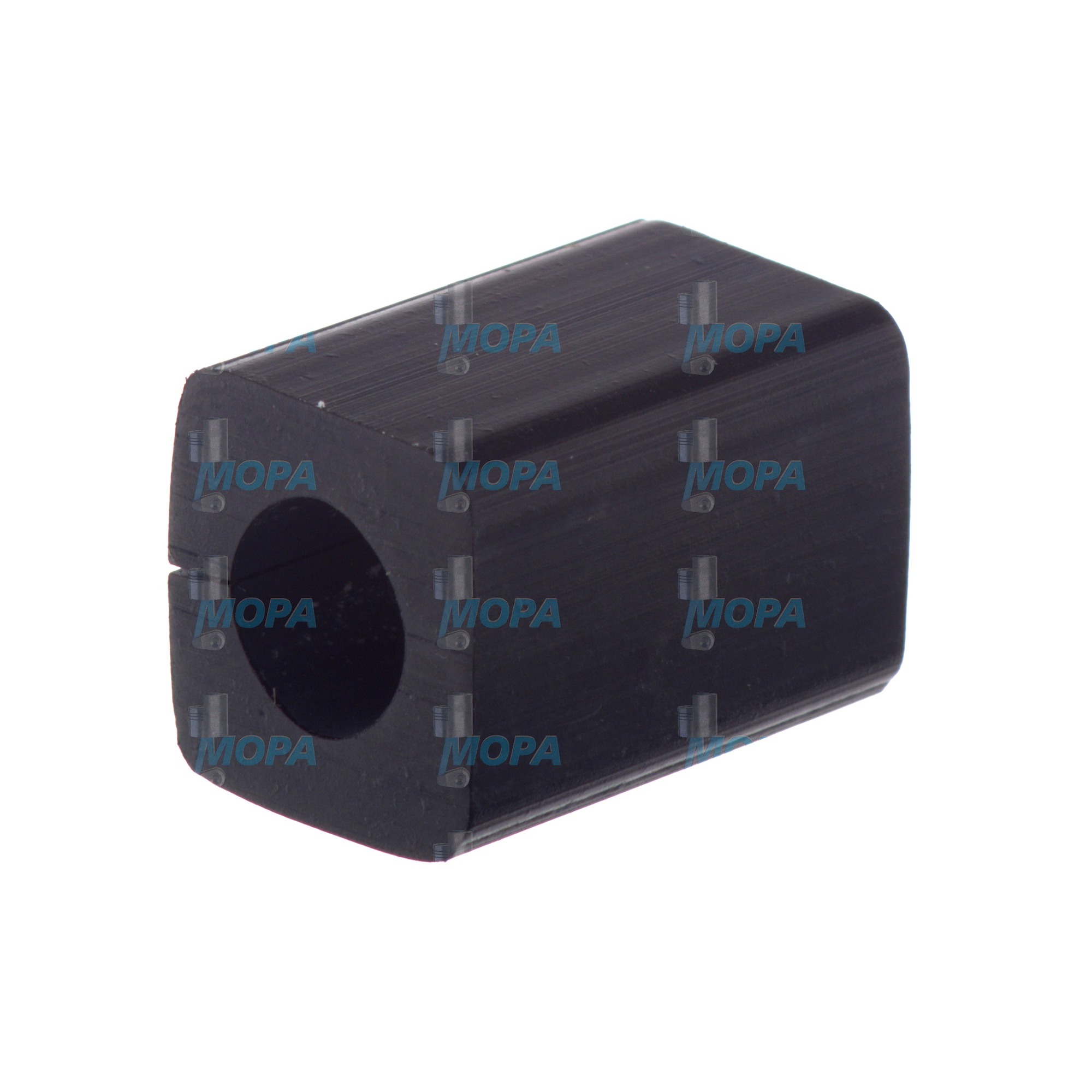

DAMPER STRIP damping elements for marine and diesel engines

Damping elements are specialized components that control vibration, structure-borne noise, and shock loads in engines and auxiliary systems. In marine and stationary power applications, they protect frames, housings, piping, and sensitive equipment from the cyclic forces generated by combustion and rotating masses. Within this category, the DAMPER STRIP is a compact, easy-to-integrate solution used between panels, brackets, covers, ducts, and skids to decouple metal interfaces, stabilize assemblies, and preserve alignment. By managing vibration energy at the source and along the transmission path, these elements help engines run smoother, quieter, and longer.

Technical function of DAMPER STRIP and damping elements in a marine engine or diesel engine

A DAMPER STRIP works by converting vibrational energy into heat through viscoelastic hysteresis. Installed as a linear profile—often rubber-based, composite, or laminated—the strip introduces a calibrated loss factor between mating surfaces. In a marine engine or diesel engine, it can be positioned under cowlings, around charge-air ducts, at heat-exchanger saddles, beneath cable trays, or along exhaust shields to reduce transmissibility and suppress resonant peaks. The result is lower stress on welds and fasteners, fewer fatigue hotspots in brackets, and improved stability of sensors and control cabinets.

Engineering teams often specify a DAMPER STRIP for marine engine acoustic treatment to reduce structure-borne noise that would otherwise propagate through the hull or foundation. In a diesel engine enclosure, it prevents metal-to-metal contact, mitigates fretting corrosion, and keeps assemblies within alignment tolerances during thermal expansion cycles. When sourced as DAMPER STRIP OEM parts, the material composition, Shore hardness, and dynamic stiffness align with the engine’s order spectrum and installation geometry, ensuring predictable damping performance over the maintenance interval.

- · Controlled damping coefficient tuned to engine orders.

- · Oil-, fuel-, and coolant-resistant elastomers and composites.

- · Reduces structure-borne noise and resonance peaks.

- · Limits fretting corrosion and fastener loosening.

- · Maintains alignment under thermal and dynamic load.

- · Straightforward retrofit or exchange during overhauls.

DAMPER STRIP importance for reliable engine operation and service life

Unchecked vibration accelerates wear on components well beyond the rotating assembly. Rigid connections transmit energy into panels and supports, leading to crack initiation, flange leaks, instrumentation drift, and premature failure of ancillary equipment. Over time, hardening or compression set of inferior damping elements reduces isolation, causing a sudden increase in noise and stress levels. In marine applications, this can compromise crew comfort metrics and compliance with onboard noise limits. In power generation, it can cause nuisance trips from vibration-sensitive sensors or electrical cabinets.

Properly specified damping elements, including a DAMPER STRIP in critical interfaces, stabilize the installation across the operating envelope—from low idle to high load transients. They protect sealing faces from micro-movement, keep bolts within preload windows by limiting dynamic shear, and preserve piping integrity under pulsation. This directly supports uptime, reduces unplanned maintenance, and extends the service life of mounts, brackets, and attached equipment.

OEM spare parts for DAMPER STRIP and damping elements: performance, reliability, and lifecycle economics

Choosing OEM spare parts suitable for damping elements ensures the compound, geometry, and bonding technology match the engine builder’s design intent. Material recipes are selected for resistance to oils, fuels, cleaning agents, and salt-laden atmospheres common in engine rooms. Dimensional accuracy delivers proper contact pressure and shear path, while validated dynamic properties keep transmissibility low at targeted frequencies.

From a budget perspective, precisely engineered DAMPER STRIP OEM parts help avoid cascading costs: fewer fatigue-related repairs, lower noise-control retrofits, and reduced downtime during overhauls. The consistent quality of these components also simplifies fleet standardization, enabling predictable maintenance planning across vessels or plants.

DAMPER STRIP OEM parts: why they make a measurable difference

By maintaining stable damping over temperature and time, OEM spare parts sustain performance between service intervals. Adhesion systems resist delamination, carriers retain stiffness, and elastomers avoid premature hardening. The net effect is dependable vibration control that safeguards performance, efficiency, and safety without introducing fit-up delays or adaptation work during installation.

MOPA: fast, secure supply of OEM DAMPER STRIP and damping elements

MOPA is an experienced and reliable partner for OEM spare parts in the Damping elements category, supplying DAMPER STRIP solutions for diesel and gas engines. Customers value the combination of speed, quality, and security in every transaction: rapid sourcing from vetted manufacturers, stringent incoming inspections, and full traceability. For purchasers and shipowners, that translates into minimized lead times and confident fit-to-function results.

Whether you need a specific DAMPER STRIP for a marine engine enclosure, isolation profiles for generator skids, or elastomeric strips for auxiliary systems, MOPA supports you with technical clarity, documentation on request, and logistics tailored to dock schedules or outage windows. The focus is straightforward—deliver the right OEM parts, on time, with the performance your assets require.

Conclusion: DAMPER STRIP and damping elements as a foundation for dependable engines

Damping elements, especially the DAMPER STRIP, are small components with a large impact on engine stability, acoustic behavior, and longevity. Selecting OEM spare parts suitable for these interfaces preserves performance, protects adjacent equipment, and optimizes lifecycle cost across marine and stationary power applications.