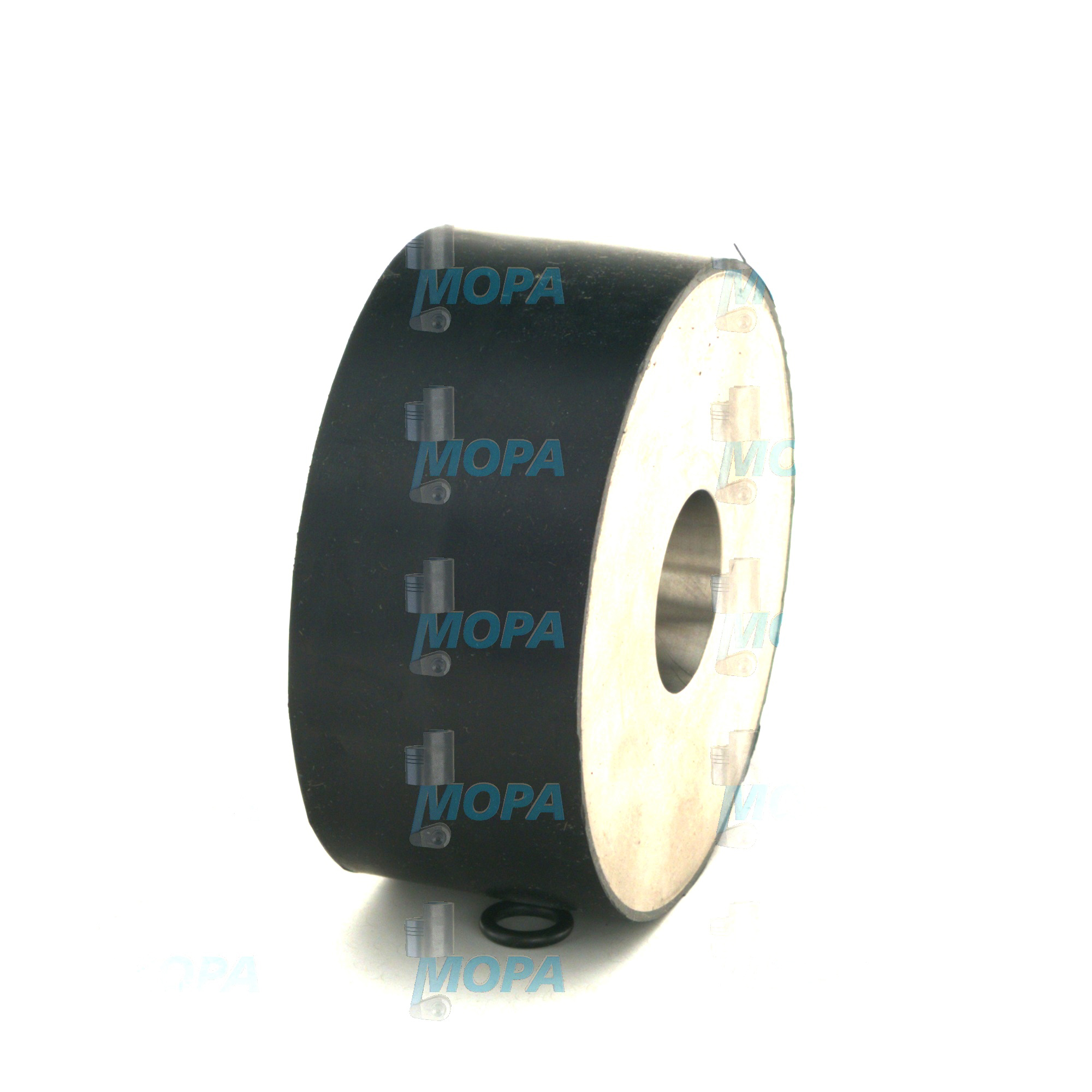

RUBBER-TO-METAL PAD damping elements for heavy-duty diesel and marine engines

Damping elements are engineered components that decouple vibrations, shocks, and structure-borne noise between an engine and its foundation. In high-output diesel and gas engines—on ships, in power plants, or in industrial installations—these parts protect the engine block, frame, and connected equipment from damaging loads. A RUBBER-TO-METAL PAD combines elastomeric layers with bonded steel interfaces to provide controlled elasticity and reliable load transfer. This hybrid design turns raw engine dynamics into manageable movements, improving comfort, stability, and component life.

Within the article category Damping elements, RUBBER-TO-METAL PAD solutions are a core choice for resilient mounts, bedframe isolators, and auxiliary equipment supports. Properly selected pads allow engines to run in their optimal range while containing vibration peaks, preventing resonance, and reducing noise levels throughout the vessel or facility. For purchasers and technical decision-makers, the right damping elements are a strategic investment in uptime and lifecycle cost control.

Technical function: Damping elements and RUBBER-TO-METAL PAD performance in engine systems

At the heart of their function, RUBBER-TO-METAL PAD assemblies convert kinetic energy from engine firing pulses and rotating masses into heat through elastomer hysteresis. The rubber layer provides specific stiffness in vertical, lateral, and fore–aft directions, while the metal plates ensure secure installation and precise load distribution. In a RUBBER-TO-METAL PAD marine engine installation, pads are arranged to carry static engine weight and absorb dynamic forces from wave-induced motions and propeller excitation. In a RUBBER-TO-METAL PAD diesel engine application, the correct stiffness and static deflection create a natural frequency well below operating RPM, minimizing transmissibility across the speed range.

Key performance parameters include Shore A hardness, static and dynamic spring rate, damping factor (loss angle), and permissible compressive and shear loads. Materials are chosen for the environment: NBR for oil and fuel resistance, EPDM for heat and ozone, and stainless or coated steel plates to resist corrosion. The rubber–metal bond—built with specialized primers and adhesives—prevents delamination under cyclic load, while anti-tear features and fail-safe geometries preserve alignment even in overload conditions. For repeatable performance, RUBBER-TO-METAL PAD OEM parts are manufactured to tight tolerances on thickness, planarity, and compound formulation, keeping the engine’s natural frequency and isolation targets consistent across installations.

- · High vibration isolation across operating RPM

- · Optimized static deflection and natural frequency

- · Robust rubber–metal bond for long service life

- · Oil, fuel, ozone, and salt-spray resistant materials

- · Predictable dynamic stiffness over temperature

- · Fail-safe designs for safety-critical mounting points

- · Precise load distribution and alignment retention

- · Reduced structure-borne noise and hull/frameline resonance

How damping elements support performance, efficiency, and safety

Effective isolation stabilizes engine alignment, preserving coupling geometry and reducing bearing loads. This helps maintain fuel efficiency by preventing misalignment-induced friction. Lower vibration also protects sensors, wiring, and pipework from fatigue, cutting unplanned downtime. Safety improves as shock events—emergency maneuvers, load steps, or start/stop cycles—are buffered, reducing peak loads transmitted to foundations and nearby systems.

Importance for engine operation and lifespan

Reliable damping elements are essential for the mechanical integrity of engines and surrounding structures. When pads harden, crack, compress permanently, or lose bond strength, transmissibility rises and vibrations propagate through the hull or frame. Consequences include accelerated wear of mounts and brackets, shaft misalignment, damaged couplings, cracked exhaust or cooling lines, premature bearing and seal failures, and non-compliance with onboard noise targets.

Routine inspection should check for rubber aging (surface cracks, glazing), compression set (loss of thickness), corrosion on metal interfaces, and any signs of delamination. Early replacement of worn Damping elements avoids cascading damage and preserves the intended isolation level for the entire engine room or plant.

Advantages of OEM spare parts suitable for Damping elements

Choosing OEM spare parts suitable for Damping elements ensures consistency in stiffness curves, material quality, and dimensional fit. These parameters are critical—small deviations in hardness or thickness can shift natural frequencies and alter overall isolation. RUBBER-TO-METAL PAD OEM parts are produced with controlled compounds, calibrated bonding processes, and validated dynamic data, which supports predictable performance from commissioning to overhaul.

For purchasers, the value is clear: better risk control, fewer reworks, and dependable lifecycle costs. For operators, it means less vibration-induced fatigue, lower noise, and stable alignment—key contributors to longer service intervals and reduced total cost of ownership.

Why specify OEM spare parts for RUBBER-TO-METAL PAD assemblies

With OEM spare parts suitable for Damping elements, you secure:

- · Verified stiffness and damping matched to engine builder specs

- · Consistent rubber compound and bonding quality

- · Accurate dimensions for bedframes and soleplates

- · Controlled tolerances that protect alignment and couplings

- · Proven corrosion protection for marine environments

- · Documentation and traceability for maintenance records

MOPA: your partner for OEM parts RUBBER-TO-METAL PAD and Damping elements

MOPA supplies OEM spare parts suitable for Damping elements with a focus on speed, quality, and security. Our team supports diesel and gas engine operators with prompt quotations, fast delivery, and meticulous part identification—covering RUBBER-TO-METAL PAD solutions for marine engine and land-based applications. We source through verified channels, provide clear documentation, and align deliveries with your maintenance windows to reduce downtime and logistics risk.

Whether you manage a fleet or a single power unit, MOPA helps you standardize on dependable isolation components and maintain performance across the engine’s lifecycle.

Conclusion

Damping elements—especially well-matched RUBBER-TO-METAL PAD assemblies—are vital to protect engines, reduce vibration, and extend service life. Selecting OEM spare parts suitable for Damping elements ensures stable isolation performance, alignment control, and reliable operating costs over time.