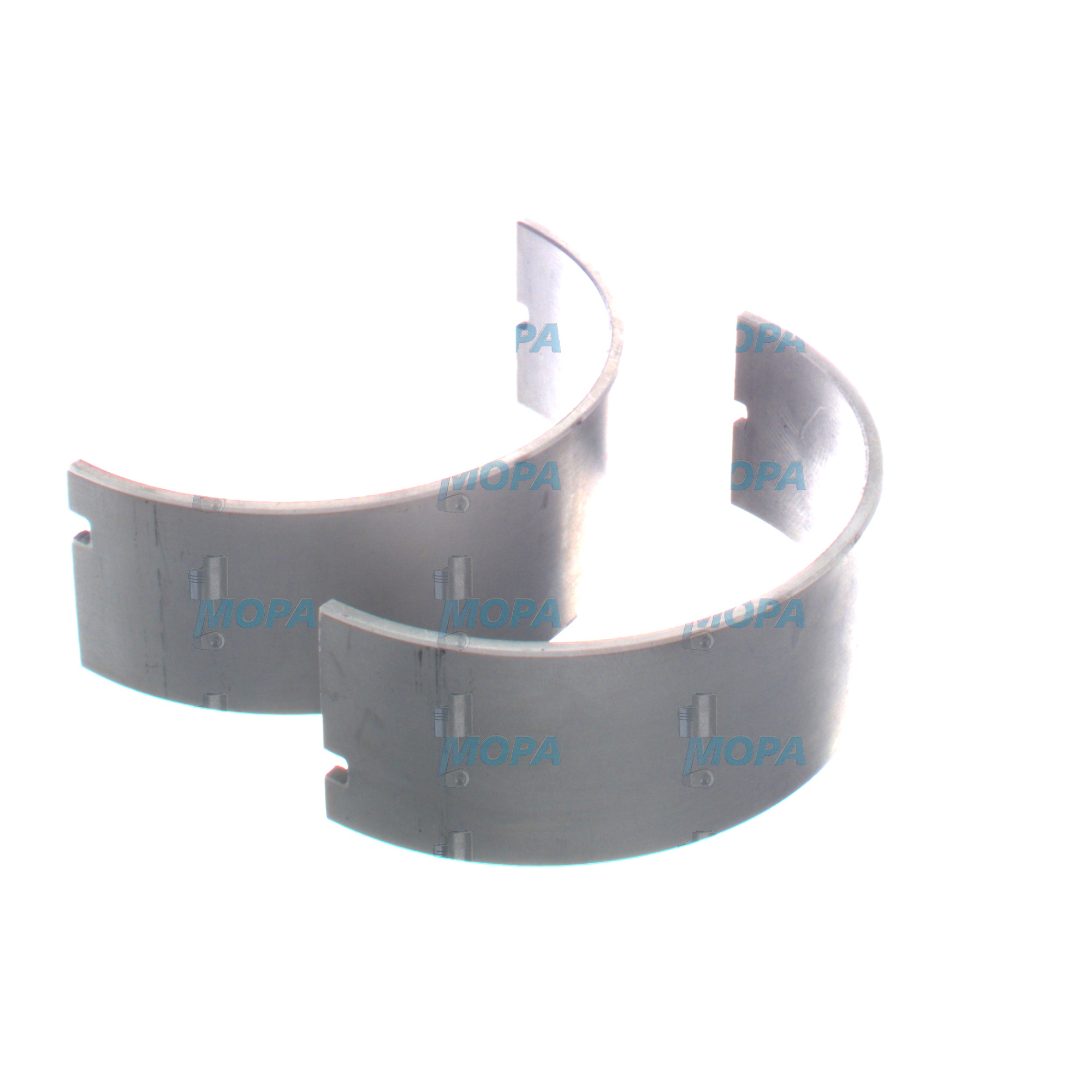

BIG END BEARING PAIR for Engine Drive Components

Engine drive components are the core mechanical elements that transform combustion energy into usable shaft power. This article category covers the parts that link piston motion to the crankshaft and onward to the gearbox, alternator, or propeller. Among these, the BIG END BEARING PAIR is pivotal: it supports the rotating crankpin interface and enables smooth, reliable power transmission in every diesel engine and marine engine. Well-engineered drive components reduce friction, stabilize the cranktrain, and protect major investments in propulsion and power generation assets.

Technical function of Engine Drive Components and the BIG END BEARING PAIR in diesel and marine engines

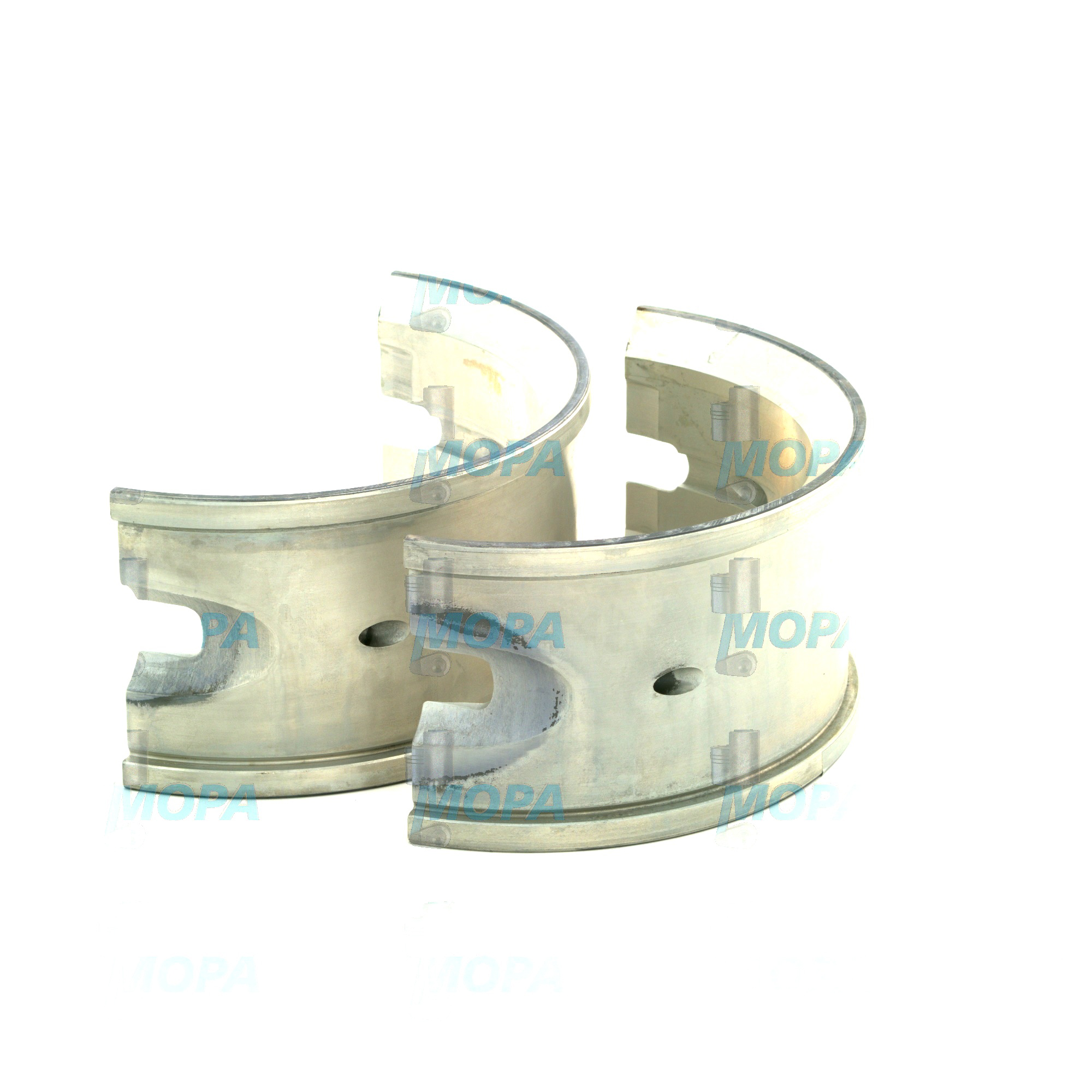

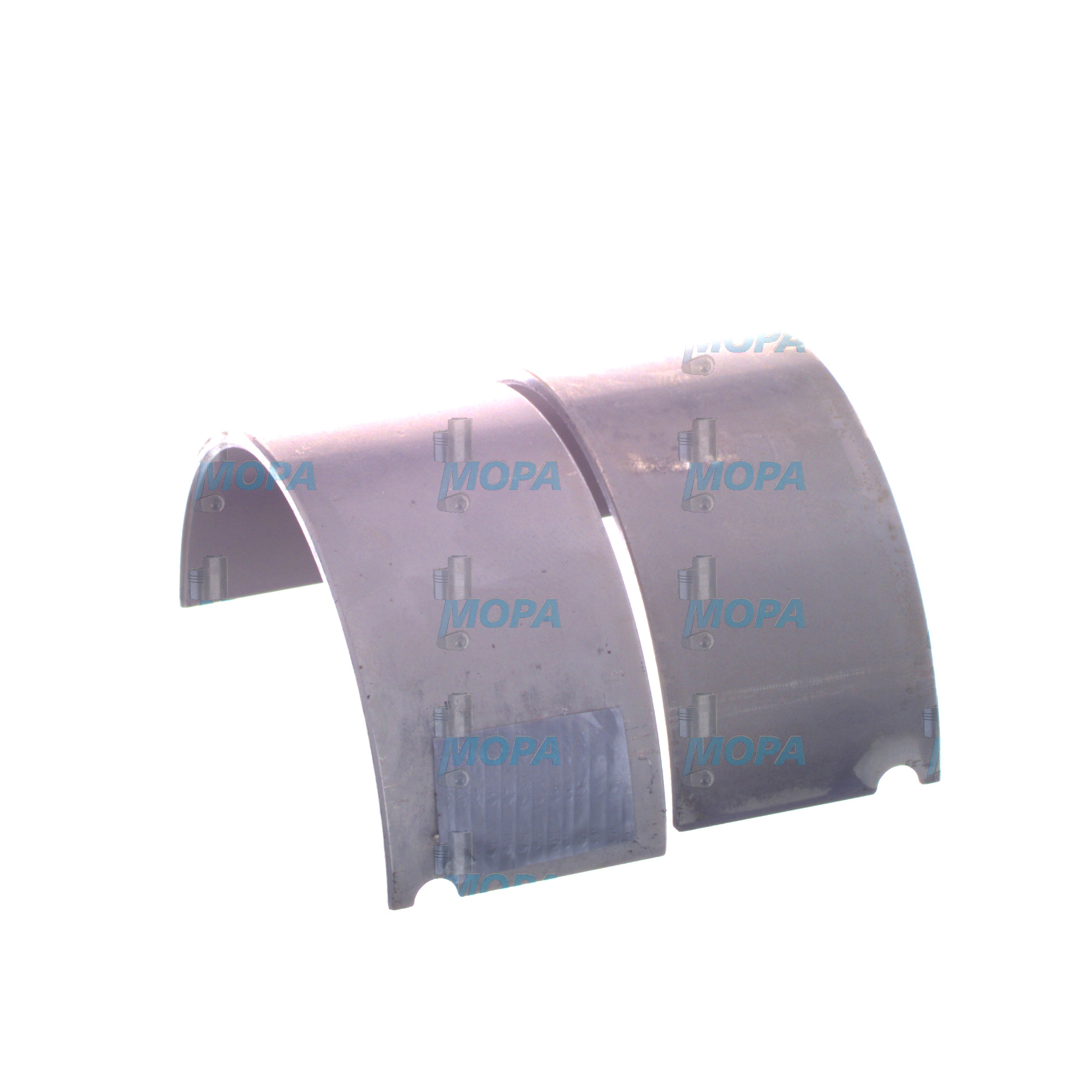

Engine drive components include the crankshaft, connecting rods, pistons, BIG END BEARING PAIR shells, main bearings, gear train, couplings, and dampers. Together they convert linear piston forces into continuous rotation under extreme thermal and mechanical loads. The BIG END BEARING PAIR—two precision half-shells installed in the big-end of the connecting rod—forms a hydrodynamic sliding bearing around the crankpin. In a diesel engine, the oil pump feeds pressurized lubricant through the crankshaft drillings; the bearing geometry and surface finish create an oil wedge that centers the journal and prevents metal-to-metal contact.

Material systems are engineered for high fatigue strength, conformability, and embedability: steel-backed shells with copper-lead or aluminum-tin layers and anti-seizure overlays protect the crankpin from scuffing and corrosion. Correct bearing crush, housing bore roundness, and specified oil clearance are essential to maintain film thickness, control temperatures, and stabilize running. In a marine engine operating at steady, high mean effective pressure, the BIG END BEARING PAIR must handle sustained loads, torsional vibrations, and occasional shock events while keeping friction losses low to safeguard fuel efficiency.

When specified as OEM parts, the BIG END BEARING PAIR is matched to journal diameter classes, fillet radii, chamfer geometry, and oil groove patterns, ensuring consistent performance across cylinders and simplifying life-cycle maintenance planning.

How a BIG END BEARING PAIR supports performance, efficiency, and safety

By maintaining precise clearances, the bearing pair minimizes eccentricity, aligns the rod under peak cylinder pressures, and dissipates heat through the connecting rod and oil circuit. This stabilizes the entire set of engine drive components, reducing vibration, limiting gear train noise, and protecting downstream couplings. The result is dependable torque delivery, controlled oil temperatures, and extended overhaul intervals—key outcomes for shipowners and plant operators who need predictable availability.

- · Hydrodynamic oil film for low friction and wear.

- · Precision tolerances for stable cranktrain alignment.

- · High fatigue resistance for heavy-duty diesel cycles.

- · Anti-seizure overlay to manage transient load spikes.

- · Effective heat dissipation via bearing and oil flow.

- · Contaminant embedability to protect the crankpin.

- · Compatibility with OEM parts specifications for fit and function.

Why Engine Drive Components and the BIG END BEARING PAIR are critical for reliability

Reliability in large engines depends on the condition of the drive line. If the BIG END BEARING PAIR wears beyond limits or is installed with incorrect clearance, hydrodynamic lubrication breaks down. Early indicators include elevated oil temperatures, pressure fluctuations, metallic debris in filters, and audible knock. Continued operation risks overlay fatigue, bearing wipe, copper exposure, and finally seizure. Consequences range from crankpin scoring and ovality to connecting rod failure and catastrophic engine damage.

Beyond the bearing itself, degraded engine drive components (gear pitting, damper deterioration, misaligned couplings) amplify dynamic loads on the bearing pair, accelerating wear and increasing fuel consumption. Properly maintained and correctly specified components preserve shaft alignment, reduce torsional oscillation, and stabilize combustion-to-rotation energy transfer—directly impacting uptime and lifecycle cost.

Advantages of OEM spare parts suitable for Engine Drive Components and the BIG END BEARING PAIR

Choosing OEM spare parts suitable for Engine drive components ensures the BIG END BEARING PAIR and related items meet the engine maker’s metallurgy, hardness, and dimensional classes. This is vital for crankpin compatibility, tang location, oil hole indexing, and overlay thickness. The result is predictable oil film behavior and consistent bearing crush across cylinders.

For procurement and technical teams, the benefits are tangible:

- · Exact fit reduces installation time and rework risk.

- · Verified material specs maintain fatigue margins under peak load.

- · Controlled surface finish and geometry protect the oil film.

- · Traceable batches support class compliance and audit trails.

- · Longer service life stabilizes budgets through fewer interventions.

- · Consistent clearances sustain efficiency and emissions performance.

- · Harmonized kits align with build lists for faster overhauls.

In a diesel engine or marine engine, a correctly matched BIG END BEARING PAIR OEM parts set maintains the intended lubrication regime and journal alignment, safeguarding both performance and total cost of ownership.

MOPA: your partner for OEM parts on BIG END BEARING PAIR and Engine Drive Components

MOPA supplies OEM spare parts suitable for Engine drive components with a focus on speed, quality, and security of supply. Whether you operate a high-speed generator set, a medium-speed marine engine, or a gas engine in CHP service, MOPA provides the BIG END BEARING PAIR, main bearings, and related cranktrain items aligned to the correct specifications. Fast order processing, rigorous inbound checks, and reliable logistics keep downtime to a minimum, while technical support helps match parts to engine serials and journal classes for a precise outcome.

Conclusion: BIG END BEARING PAIR and Engine Drive Components

The BIG END BEARING PAIR sits at the heart of Engine drive components, maintaining the oil film that makes high-load power conversion possible. Specifying OEM spare parts suitable for this category protects reliability, efficiency, and service life—delivering stable operation and predictable costs across diesel and marine engine fleets.