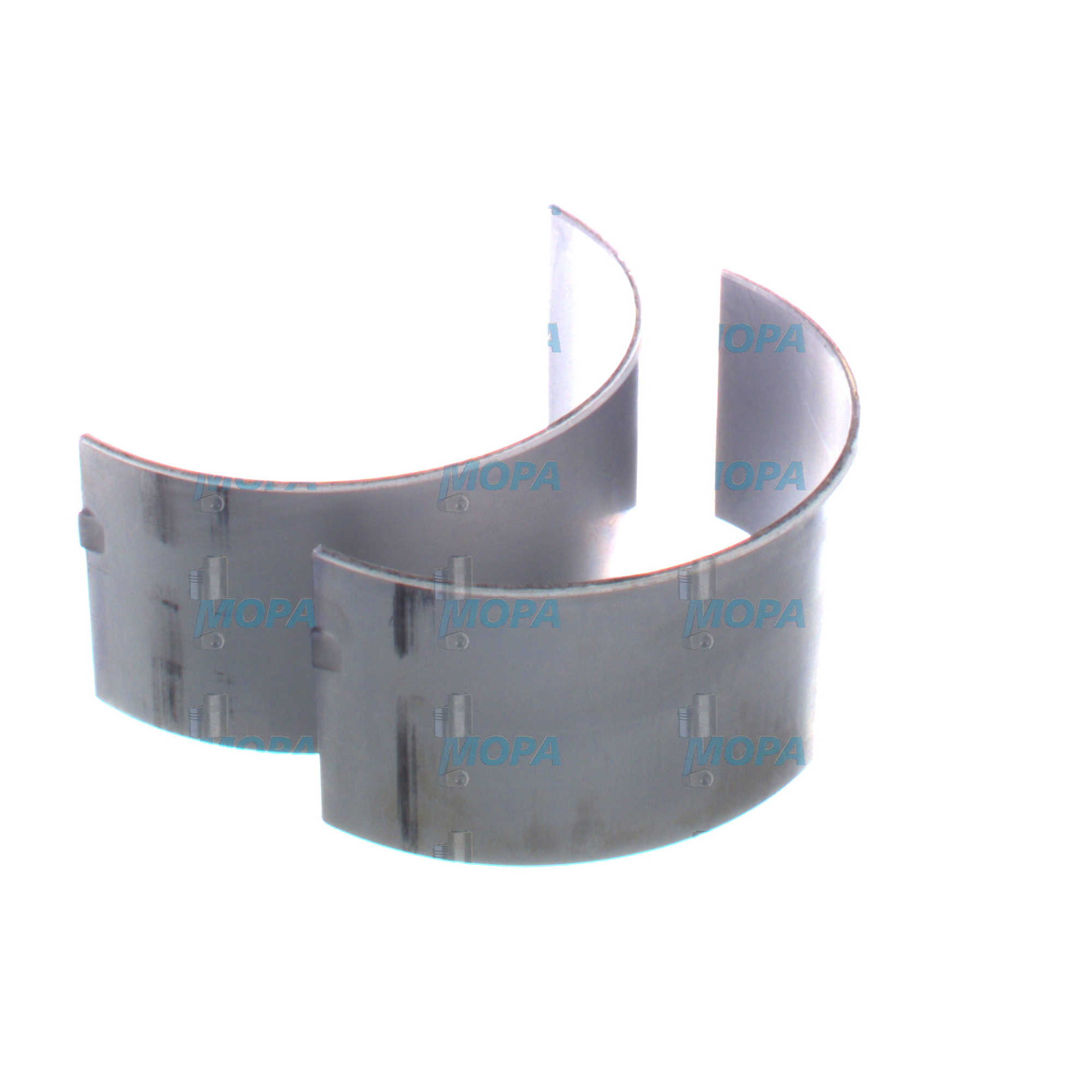

BIG END BEARING SET – Engine drive components for dependable power transmission

Engine drive components form the mechanical backbone that turns combustion energy into usable torque. This article category includes the connecting rod assemblies, BIG END BEARING SET elements, main bearings, crankshafts, flywheels, gear trains, torsional vibration dampers, and couplings that transmit power from piston to propeller, generator, or drivetrain. In heavy-duty diesel and gas applications, especially in a marine engine, these parts operate under high loads, elevated temperatures, and continuous duty cycles. Their precision, materials, and lubrication behavior directly influence performance, efficiency, emissions, and uptime.

Technical function: Engine drive components and the BIG END BEARING SET in diesel and marine engines

Within the drive train, the BIG END BEARING SET is the hydrodynamic interface between the connecting rod and the crankshaft journal. In a diesel engine or a large-bore marine engine, these shells carry extreme cyclic loads as combustion forces act on the piston and rod. The bearing’s job is to maintain a stable oil film that separates metal surfaces, minimizes friction, supports shock loads, and controls heat transfer away from the journal. Typical BIG END BEARING SET constructions use tri-metal or bi-metal metallurgy—steel back for rigidity, a copper-lead or aluminum-tin intermediate layer for load capacity, and a soft overlay (babbitt) for conformability and seizure resistance. Key features include correct crush fit in the rod cap, locating tangs for seating, tailored oil holes/grooves, and surface finishes that promote hydrodynamic lift at start-up and full load.

Beyond the bearing itself, engine drive components must work as a balanced system. Crankshaft hardness and surface finish, connecting rod alignment, bolt preload, and oil supply quality determine how the BIG END BEARING SET performs over thousands of hours. Proper clearances—matched to journal diameter, viscosity, and operating temperature—ensure oil pressure stability and prevent metal-to-metal contact. In practice, tiny deviations in ovality or taper, contamination in the oil circuit, or insufficient bolt stretch can escalate localized film breakdown, leading to premature wear. When specified and installed correctly, BIG END BEARING SET OEM parts help stabilize friction losses, protect journals from scoring, and support the engine’s designed power density.

- · Robust load capacity for high BMEP operation.

- · Precision clearances for stable oil pressure.

- · Optimized metallurgy for fatigue and seizure resistance.

- · Balanced rotating masses for smooth running and low vibration.

- · Engineered lubrication paths for reliable film formation.

- · Tight dimensional tolerances for consistent fit and crush.

- · Heat management to dissipate localized thermal peaks.

- · Corrosion and cavitation resistance for long service life.

Why engine drive components are critical for reliability and service life

Reliability in propulsion and power generation hinges on the health of engine drive components. When bearings, rods, and crankshafts operate within specification, the engine maintains correct timing, oil pressure, and vibration levels. If a BIG END BEARING SET wears beyond tolerance, symptoms can include rising metal content in oil analysis, falling oil pressure at idle, elevated bearing temperatures, and audible knock under load. Left unchecked, this can progress to overlay fatigue, copper streaking, journal scoring, and ultimately bearing seizure.

Similar cause-and-effect chains exist across the drive system: a misaligned connecting rod accelerates edge loading; degraded torsional dampers increase crank stress; insufficient rod bolt preload risks cap fretting; contaminated oil reduces film thickness and shortens bearing life. Protecting the crank-train is therefore central to avoiding forced outages, collateral damage (piston, liner, turbocharger debris ingestion), and costly dry-dock or shutdown periods.

Risks of neglected BIG END BEARING SET clearances

Excessive clearance compromises hydrodynamic lift and increases impact loading at TDC/BDC reversal. Too little clearance restricts oil flow, drives up temperatures, and can wipe the overlay. Both conditions shorten life and can propagate damage to journals and adjacent engine drive components. Routine micrometer checks, plastigage verification during overhauls, and trending oil analysis are best practices to preserve bearing integrity.

Advantages of OEM spare parts suitable for engine drive components

OEM spare parts suitable for engine drive components safeguard dimensional fidelity, metallurgy, and surface finish that the engine designer specified. For a BIG END BEARING SET, this means consistent backing hardness, controlled overlay thickness, accurate oil groove geometry, and validated crush values—factors that directly influence film stability, friction, and thermal behavior. Using these components supports:

Performance: Maintains designed bearing clearances, enabling stable oil pressure, lower friction, and dependable torque delivery across the load range.

Reliability: Proven fatigue strength and coating systems resist cavitation and debris scoring, reducing the likelihood of unscheduled stops.

Budget: Correct fit and predictable wear patterns reduce rework, limit journal grinding, and shorten overhaul durations—lowering total lifecycle cost.

Service life: Materials and geometries validated by the engine platform extend intervals between major services and help protect adjacent parts like crankshafts and connecting rods.

Whether you need a BIG END BEARING SET for a diesel engine, a BIG END BEARING SET for a marine engine, or BIG END BEARING SET OEM parts to align with fleet standards, consistent specification is the most practical path to sustained uptime.

MOPA – your partner for OEM spare parts engine drive components

MOPA supports purchasers, shipowners, and technical teams with fast, secure sourcing of OEM parts for diesel and gas engines. From a single BIG END BEARING SET to complete engine drive component packages—main bearings, rod bolts, thrust washers, crankshafts—MOPA focuses on speed, quality, and transactional security. You benefit from precise cross-referencing, documentation and traceability, careful export packaging, and logistics tailored to yard schedules or offshore deliveries. Our team understands fit-up details (clearances, journal codes, bearing classes) and helps align parts with engine serials, revision levels, and class requirements, minimizing risk during overhauls and planned maintenance.

Conclusion: Engine drive components and the role of the BIG END BEARING SET

Engine drive components are central to converting combustion energy into reliable mechanical power, and the BIG END BEARING SET is a critical interface that protects the crankshaft and stabilizes performance. Selecting OEM spare parts suitable for engine drive components preserves design intent, supports uptime, and delivers predictable lifecycle economics—on land and at sea.