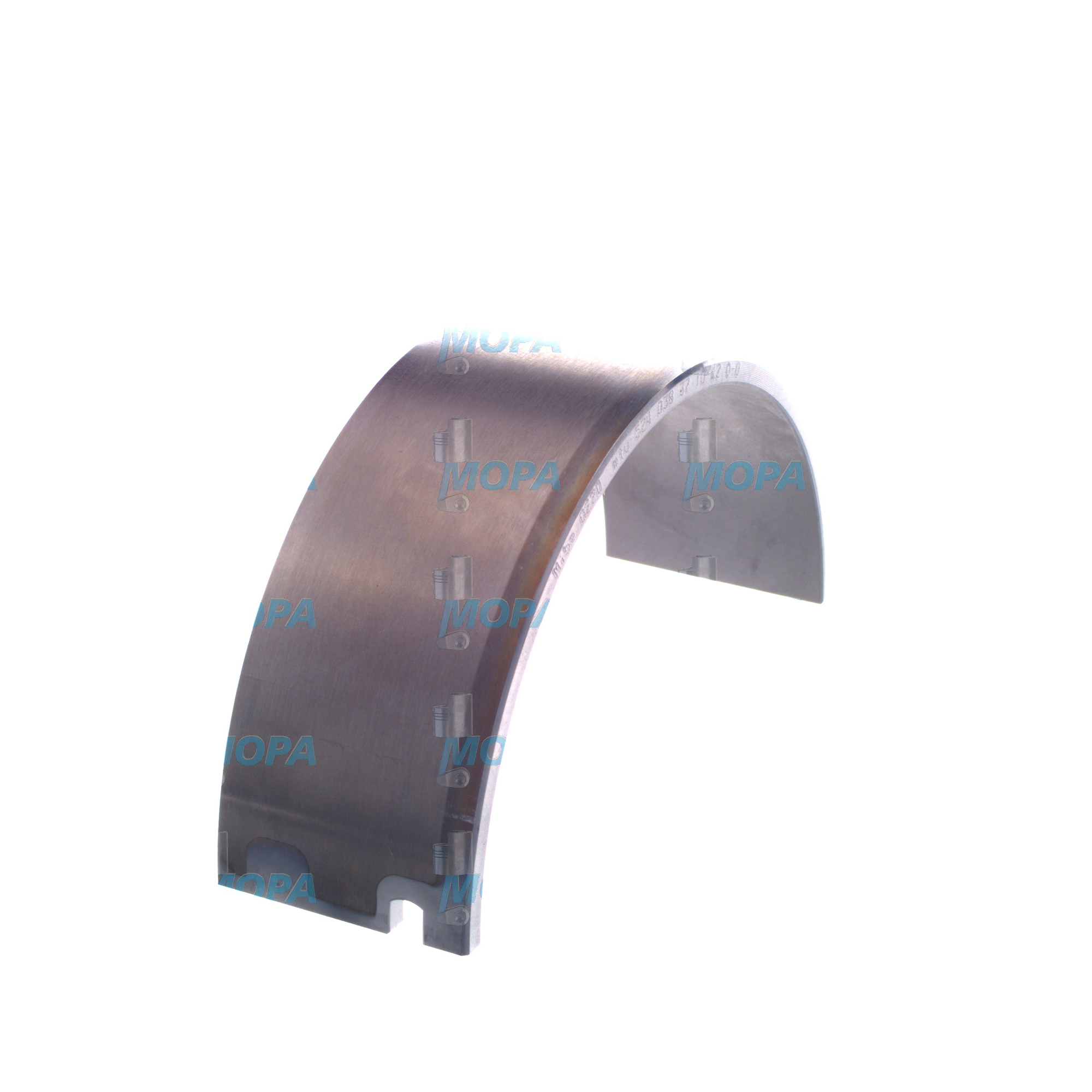

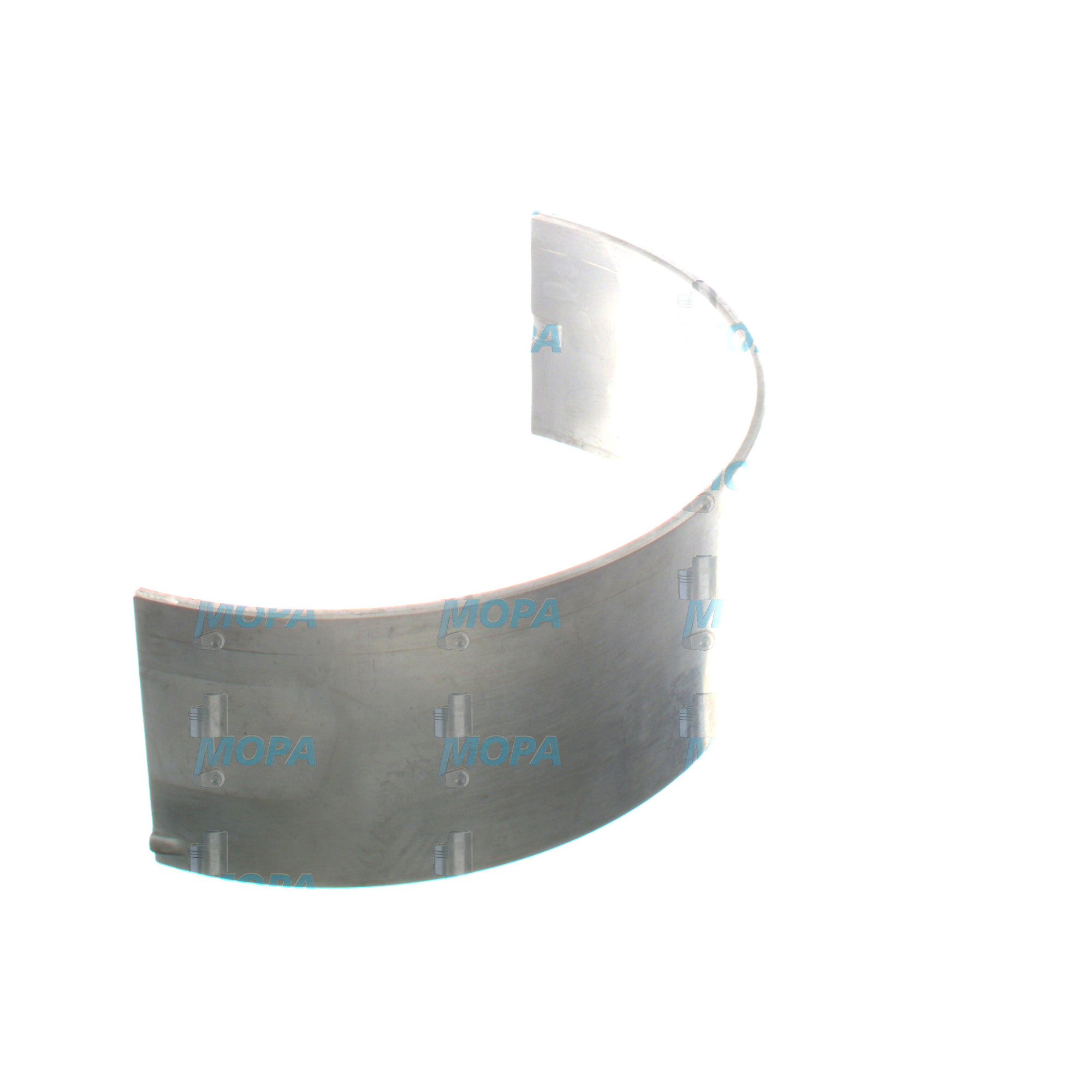

BIG END BEARING SHELL in Engine Drive Components

Engine drive components transform combustion energy into rotational power with precision and durability. This article category covers the critical moving parts that transmit force from the piston to the crankshaft, keep rotating masses aligned, and maintain the correct clearances for safe, efficient operation. Within this group, the BIG END BEARING SHELL is a central element that ensures smooth crankshaft rotation and protects high-value engine structures from wear. For shipowners, operators, and technical buyers, selecting the right engine drive components is decisive for uptime, lifecycle costs, and compliance with maintenance strategies.

In medium- and high-speed engines alike, engine drive components must withstand extreme loads, varying lubrication conditions, and thermal cycling. The BIG END BEARING SHELL is a prime example of how seemingly “simple” parts deliver sophisticated performance: controlled metallurgy, precise geometry, and repeatable tolerances are what keep heavy diesel and gas engines running reliably across long service intervals.

Technical function of Engine Drive Components and the BIG END BEARING SHELL in a diesel engine

Engine drive components include the connecting rod, piston pin, crankshaft, and associated bearings and fasteners. Their shared task is to convert the reciprocating motion of the piston into the rotary motion of the crankshaft while minimizing friction, vibration, and heat. The BIG END BEARING SHELL in a diesel engine sits at the big end of the connecting rod, forming a replaceable, low-friction interface with the crankpin journal. Under operating oil pressure, it supports the hydrodynamic lubrication film that carries the load at each combustion event.

Material composition and geometry are key. Most shells use a steel backing for strength, a copper-lead or bronze intermediate layer for load capacity and thermal conductivity, and a soft overlay (often tin-aluminum) to embed contaminants and protect the journal during transient events. Carefully engineered crush, eccentricity, and oil groove patterns stabilize the oil wedge and prevent metal-to-metal contact. Correct bearing clearance—verified during assembly—ensures the oil film forms quickly and remains stable from idle to full load. When specified and installed correctly, a BIG END BEARING SHELL for a marine engine safeguards the crankshaft against scoring, pitting, and heat-induced deformation.

Clearances, roundness, and surface finish must align tightly with the crankshaft specification. Any deviation can cause mixed or boundary lubrication, increasing temperatures and wear. This is why BIG END BEARING SHELL OEM parts are produced with strict process control: consistent overlay thickness, controlled hardness, and dimensional accuracy deliver repeatable behavior across fleets and overhauls.

- · High load capacity for sustained peak firing pressures

- · Stable hydrodynamic oil film across changing speeds and loads

- · Precisely engineered clearance and crush for reliable seating

- · Trimetal layer architecture for strength and embeddability

- · Optimized oil grooves and chamfers for uniform lubrication

- · Corrosion and fatigue resistance under marine conditions

- · Consistent surface finish to protect crankpin journals

- · Interchangeability within the engine family for efficient service

Importance for engine operation: Engine Drive Components and BIG END BEARING SHELL for a marine engine

The reliability of a propulsion or genset package hinges on the health of its engine drive components. The BIG END BEARING SHELL acts as the sacrificial, precisely engineered interface that protects more expensive parts—particularly the crankshaft. When bearing condition deteriorates, early symptoms include rising oil temperatures, pressure fluctuations, and metallic debris in filters. If not corrected, the result can be journal scoring, loss of clearances, vibration, and, ultimately, connecting rod failure or crank seizure.

Common failure drivers include oil contamination, misalignment, overloading, inadequate lubrication pressure, and improper torqueing during assembly. Cavitation erosion can occur on the unloaded side of the shell; overlay fatigue can appear as micro-cracking under cyclic stress; and localized hot spots may form where clearances are incorrect. Routine condition monitoring—oil analysis, endoscopic inspection, and clearance checks—combined with timely replacement of the BIG END BEARING SHELL in a diesel engine ensures stable performance across long voyages and demanding duty cycles.

Advantages of OEM spare parts suitable for Engine Drive Components and BIG END BEARING SHELL OEM parts

Using OEM spare parts suitable for engine drive components preserves the engine’s designed performance envelope. The dimensional accuracy and metallurgical consistency in BIG END BEARING SHELL OEM parts ensure the correct oil film behavior, which translates into lower friction losses, stable temperatures, and reduced wear. This directly affects fuel efficiency, emissions stability, and the lifespan of crankshaft and connecting rod assemblies.

BIG END BEARING SHELL OEM parts for diesel engine performance and lifecycle

For purchasers and technical managers, the business case is clear. OEM spare parts suitable for engine drive components offer controlled tolerances for predictable clearances, traceable materials for consistent fatigue resistance, and validated surface finishes that minimize run-in risk. That precision delivers fewer unplanned stoppages and protects overhaul budgets by preventing secondary damage to high-value components. In addition, documentation and conformity with the engine maker’s specification support streamlined class or internal compliance, especially critical in marine applications where downtime is costly.

From a lifecycle perspective, correct bearing metallurgy and geometry lower the risk of mixed lubrication and subsequent seizure. Over time, this reduces oil consumption, maintains stable vibration signatures, and prolongs the service interval of related components such as crankpins and con-rods. The result is durable, repeatable performance under continuous operation—exactly what shipowners and power plant operators require.

MOPA as your partner for OEM spare parts: Engine Drive Components and BIG END BEARING SHELL

MOPA is an experienced, reliable partner for OEM spare parts in the category of engine drive components, including the BIG END BEARING SHELL. Customers benefit from fast response times, verified quality, and secure trade processes purpose-built for diesel and gas engines. MOPA supports marine engine operators, power generation sites, and industrial users with technical expertise, documentation support, and efficient global logistics.

With MOPA, purchasers can count on clear traceability, batch consistency, and professional handling—from inquiry to delivery. The result is reduced procurement risk, quick availability of critical parts, and confidence that installed components will perform as specified across the engine’s service life.

Conclusion: Engine Drive Components and BIG END BEARING SHELL in focus

Engine drive components are the backbone of reliable power transmission, and the BIG END BEARING SHELL is pivotal in protecting the crankshaft while sustaining efficient, low-friction operation. Selecting OEM spare parts suitable for this category secures performance, extends service life, and optimizes maintenance budgets.

With the right specification and a trusted partner like MOPA, operators can protect assets, minimize downtime, and keep diesel and gas engines running safely and efficiently—voyage after voyage, shift after shift.