BIG END BUSH in Engine Drive Components

Engine drive components form the backbone of every power unit, converting combustion energy into reliable, controllable torque. As an article category, Engine drive components include the parts that transmit and stabilize loads between the piston, connecting rod, crankshaft, and the driven equipment. Bearings, bushings, couplings, gear trains, and vibration dampers work together to keep forces aligned, friction minimized, and motion precise—under continuous thermal and mechanical stress.

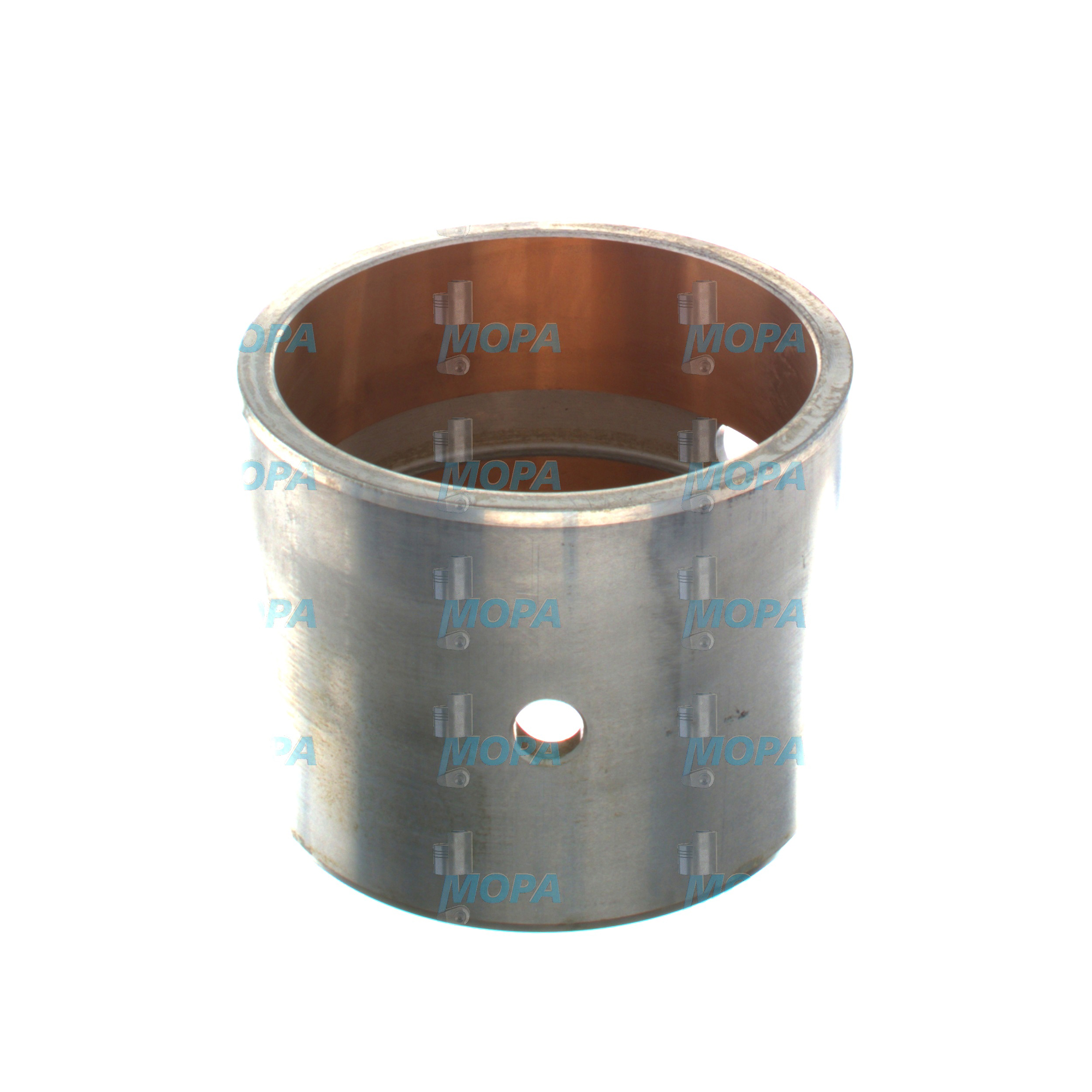

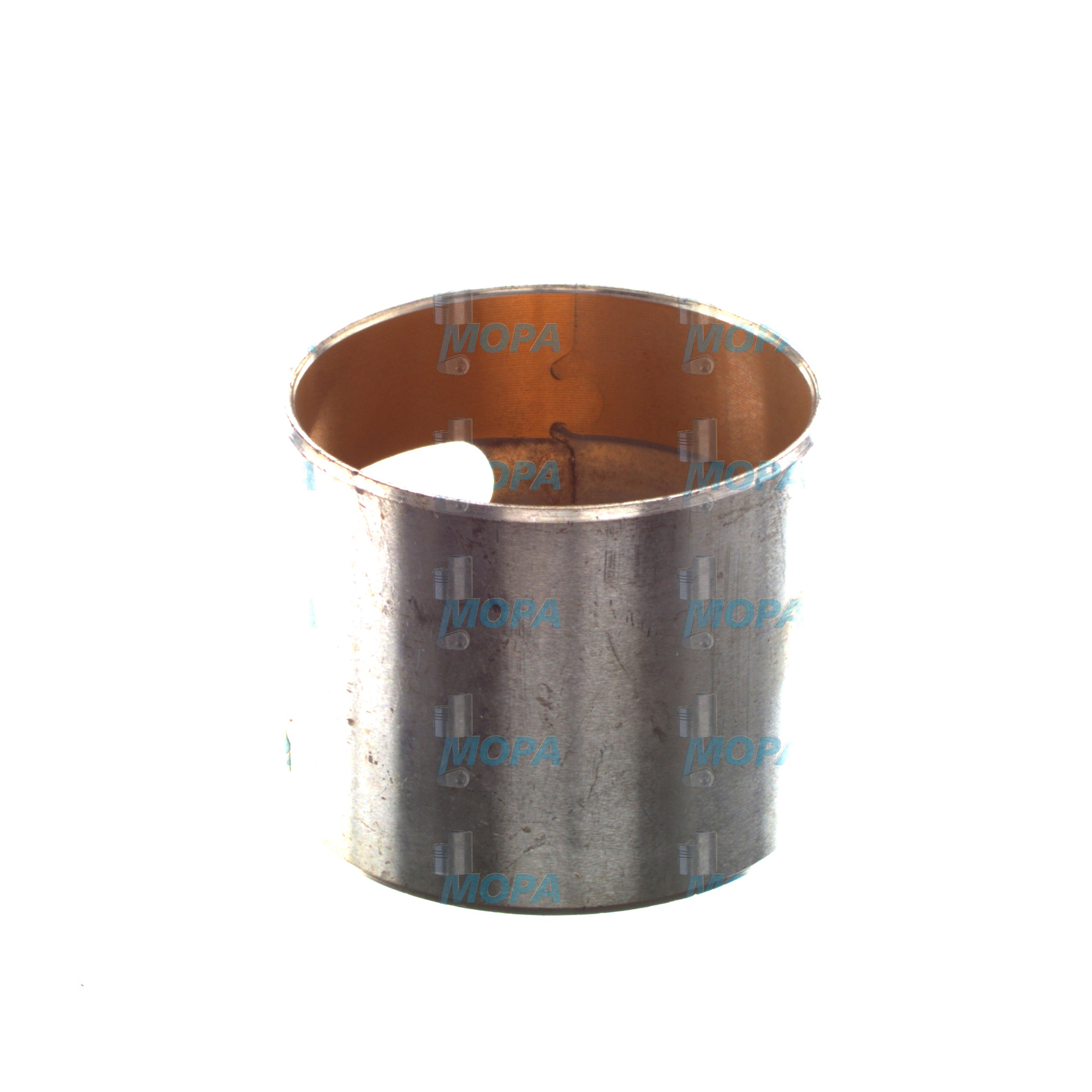

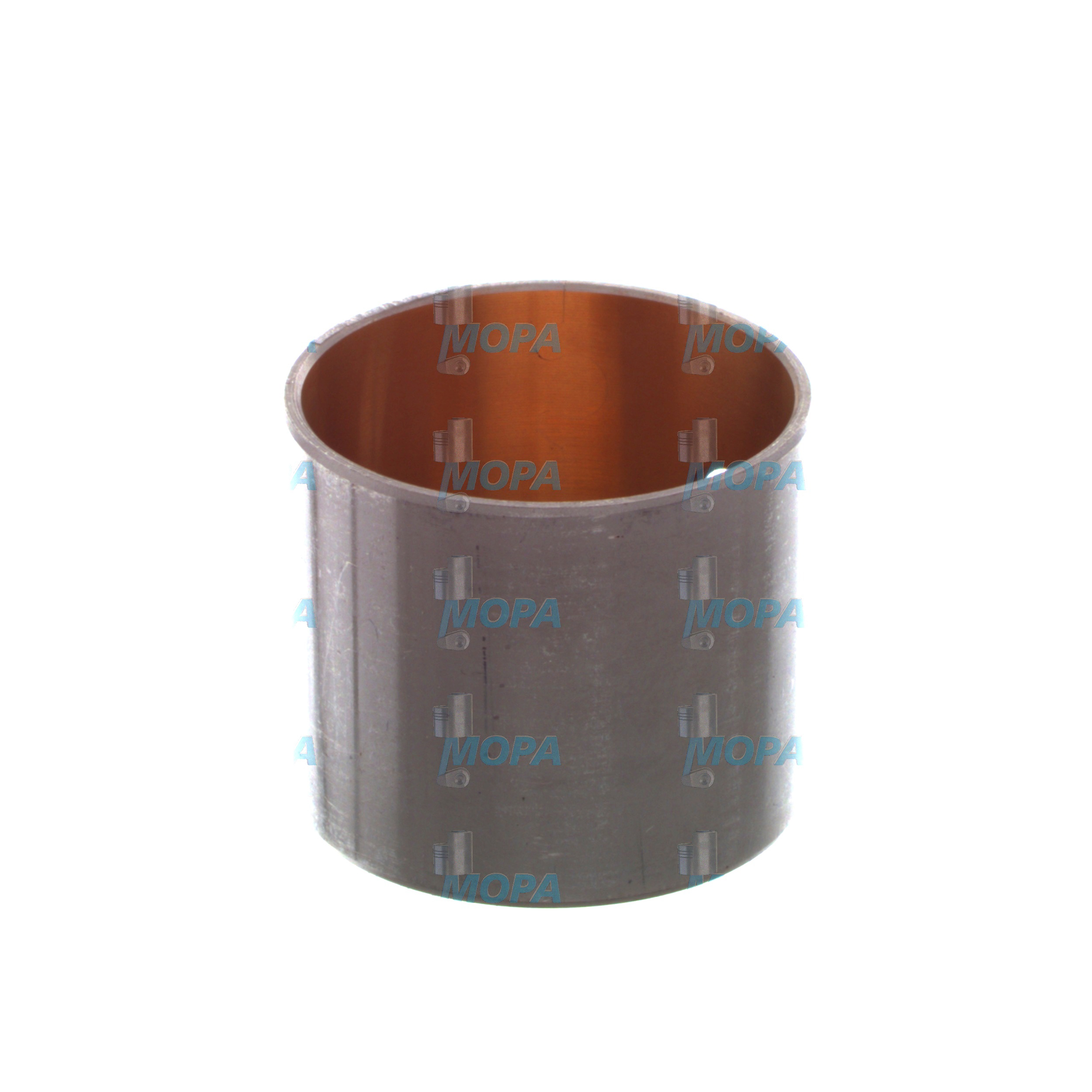

Within this system, the BIG END BUSH is a pivotal element. It supports the crankpin interface at the connecting rod’s big end and enables smooth rotation on a thin, pressurized oil film. In a marine engine or high-output diesel engine, this plain bearing has to tolerate high mean effective pressures, cyclic loads, and fluctuating temperatures while protecting both the connecting rod and crankshaft from wear. As a result, Engine drive components—and especially the BIG END BUSH—are decisive for performance, efficiency, and operational safety.

Technical function of Engine drive components and the BIG END BUSH in a diesel engine

Engine drive components orchestrate the conversion of reciprocating motion into rotary output. The piston transfers force to the connecting rod; the rod’s BIG END BUSH rides on the crankpin, and the crankshaft translates the linear thrust into rotation. Surrounding parts—main bearings, thrust elements, couplings, and torsional dampers—ensure alignment, absorb shocks, and manage torsional vibration. When designed and maintained correctly, this chain of parts minimizes energy losses and heat generation, supports high specific loads, and ensures stable lubrication even at low speeds and high cylinder pressures typical of marine and stationary gas engines.

The BIG END BUSH for a diesel engine operates under hydrodynamic lubrication. Correct radial clearance allows an oil wedge to form as the journal rotates, separating metal surfaces and carrying load on a pressurized film. Material architecture is critical: tri‑metal or bi‑metal bearing systems with a steel backing, intermediate layer, and soft overlay balance fatigue strength, embeddability, and seizure resistance. Oil grooves and holes are precisely placed to sustain film integrity across the load zone, while the bush’s crush and interference fit stabilize heat transfer and prevent spin. In a marine engine, the BIG END BUSH must also resist corrosive environments, start‑stop cycles, and long service intervals; in this context, BIG END BUSH OEM parts optimized for the application secure dependable lubrication at both idle and full load.

- · Precise torque transmission from piston to crankshaft.

- · Hydrodynamic oil film stability under high cyclical loads.

- · Low friction and controlled wear through advanced bearing layers.

- · Tight clearances for hot/cold running conditions.

- · Resistance to cavitation, fretting, and corrosion.

- · Effective heat dissipation from bearing to connecting rod.

- · Compatibility with diesel and gas engine duty cycles.

- · Measurable performance via oil pressure, temperature, and vibration trends.

Hydrodynamic behavior of a BIG END BUSH in a marine engine

At operating speed, the crankpin drags oil into a converging gap, building pressure that centers the journal. If clearance is too tight, the oil film collapses and heat escalates; if too loose, peak film pressure drops and the journal contacts the overlay. Proper bush geometry, sphericity, and surface finish sustain film thickness through reversal and top-dead-center load spikes. This precise interplay is why the BIG END BUSH is central to both mechanical efficiency and bearing life in demanding marine and power‑generation settings.

Why Engine drive components—especially the BIG END BUSH—are critical for reliability

Durable Engine drive components protect the most expensive assets in a powertrain: the crankshaft and connecting rods. When a BIG END BUSH wears past limits, symptoms cascade quickly—elevated bearing metal in oil analysis, rising bearing temperature, reduced oil pressure margin, and audible knock under load. Continued operation can lead to overlay fatigue, lining delamination, ovality, scoring of the crankpin, and ultimately seizure. The knock‑on effects include unplanned downtime, major overhauls, and potential secondary damage to pistons, liners, or gear trains.

Conversely, a healthy BIG END BUSH maintains alignment, smooths torque delivery, and lowers frictional losses. It protects oil quality by reducing debris generation, supports consistent fuel consumption, and stabilizes emissions by keeping combustion timing predictable. For fleet owners and plant operators, that translates into higher availability and longer overhaul intervals—key metrics for lifecycle cost control.

Advantages of OEM spare parts suitable for Engine drive components and the BIG END BUSH

Choosing OEM spare parts suitable for Engine drive components delivers measurable value from day one of installation. These parts are engineered for the exact crankpin diameter, bearing crush, oil groove geometry, and overlay thickness specified by the engine maker—ensuring the oil film forms as designed across the entire duty range. For a BIG END BUSH, this means proven metallurgy, controlled porosity, and consistent hardness that resist fatigue at high mean effective pressure.

Beyond fit and metallurgy, OEM spare parts suitable for a BIG END BUSH and related components offer predictable installation and performance outcomes. Machining tolerances, edge chamfers, and bore alignment are held tightly, reducing time spent on blue‑printing, line‑boring, or trial fitting. Traceable production and batch consistency support confident maintenance planning across multi‑engine fleets.

Why OEM spare parts suitable for the BIG END BUSH and Engine drive components make sense:

- · Exact clearances and geometry for stable hydrodynamic lubrication.

- · Verified material systems for fatigue strength and seizure resistance.

- · Consistent surface finish and overlay thickness for low friction.

- · Faster, risk‑reduced installation with predictable crush and fit.

- · Documented traceability to support compliance and audits.

- · Longer service life and optimized total cost of ownership.

MOPA: your partner for OEM spare parts BIG END BUSH and Engine drive components

MOPA supplies OEM spare parts suitable for Engine drive components across leading diesel and gas engine platforms—covering the BIG END BUSH, main bearings, thrust elements, couplings, and more. Customers benefit from fast response, stringent quality control, and secure global logistics that keep vessels and plants on schedule. From marine engine operators to power‑generation sites, MOPA combines technical expertise with transparent processes to ensure you receive the right components, on time, with full part traceability.

Our team supports specification checks (dimensions, materials, clearances), cross‑references part numbers, and aligns deliveries with maintenance windows. With regional stock, export documentation support, and consolidated shipments, MOPA streamlines procurement while protecting your operational uptime.

Conclusion: BIG END BUSH and Engine drive components matter

Engine drive components determine how efficiently and safely an engine turns fuel into productive power, and the BIG END BUSH is a core element in that chain. Selecting OEM spare parts suitable for the BIG END BUSH and related components secures lubrication stability, reliability, and long service life—while safeguarding your budget through predictable performance.