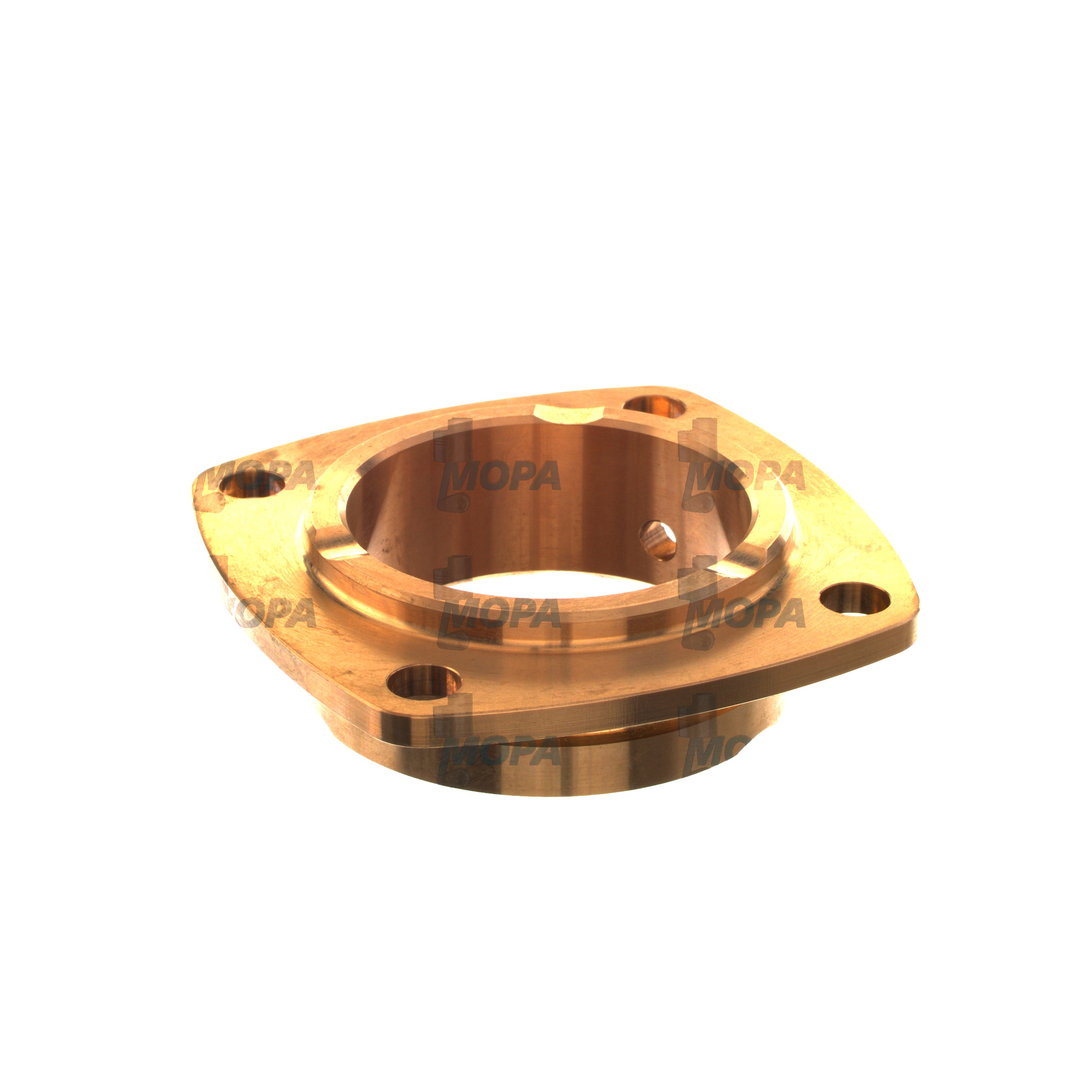

CAMSHAFT BEARING PAIR for Engine drive components

Engine drive components are the mechanical backbone that transmits, times, and stabilizes power inside diesel and gas engines. This article category spans the full torque path from the crankshaft to the valve train and auxiliaries, including gears, timing chains or belts, idlers, sprockets, dampers, couplings, guides, tensioners, and the precision supports such as the CAMSHAFT BEARING PAIR. Together, these parts secure exact valve timing, fuel injection phasing, and smooth rotation under continuous load. In marine engine and power generation contexts, they are fundamental to uptime, fuel economy, and emissions compliance.

Engine drive components and the CAMSHAFT BEARING PAIR in diesel and marine engines

Within engine drive components, the CAMSHAFT BEARING PAIR performs a critical task: it supports the camshaft radially and axially while maintaining a stable hydrodynamic oil film. In a high-duty diesel engine, the bearings must tolerate cyclical loads from cam lobes, fluctuating oil temperatures, and torsional vibrations transmitted by the timing drive. In a marine engine with prolonged base-load operation, the same bearing pair must do so for extended service intervals without losing dimensional stability or film integrity.

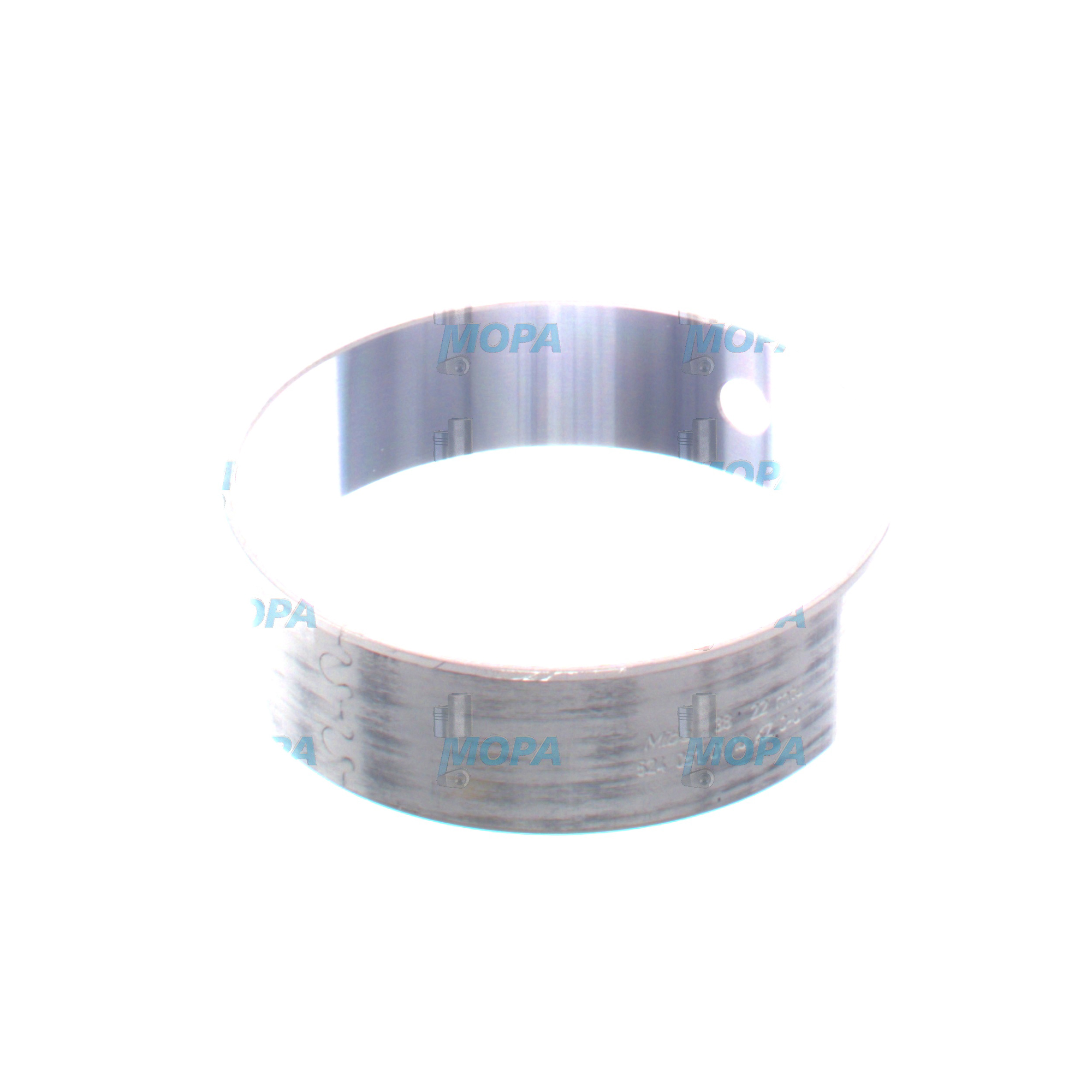

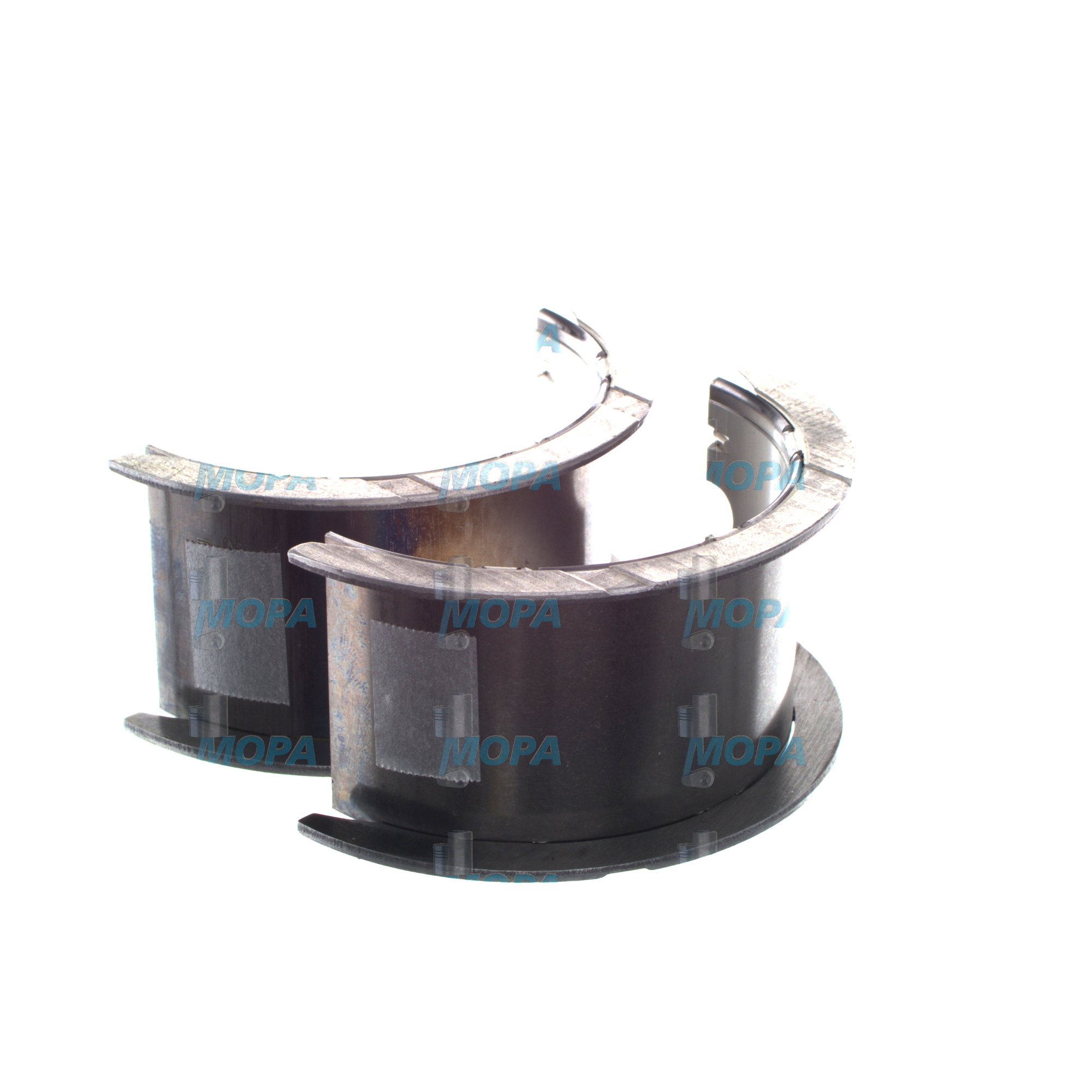

Technically, the camshaft journals ride on a pressurized oil wedge formed by the bearing’s geometry, surface finish, and clearance. When the geometry and clearances are correct, the camshaft remains precisely located relative to the timing gears or chain. That stability keeps valve events and injection pump timing exactly where the engine map expects them, improving combustion efficiency and lowering specific fuel consumption. Using CAMSHAFT BEARING PAIR OEM parts ensures the metallurgy, overlay composition (e.g., tri-metal or Al-Sn), crush, and oil-groove architecture match the engine maker’s specification—vital for durability when combined with hardened gear trains and tensioned chain systems.

In practice, small deviations in bearing roundness, housing bore alignment, or clearance can propagate into timing scatter, NVH issues, or accelerated wear of cam lobes, followers, and drive gears. Conversely, correctly specified components—gears with ground tooth profiles, accurate tensioners, and a spec-true CAMSHAFT BEARING PAIR for a marine engine or industrial diesel—deliver quiet operation, predictable valve motion, and stable long-term performance.

Key characteristics and advantages of engine drive components

· Precise torque transmission from crankshaft to camshaft, pumps, and auxiliaries.

· Stable hydrodynamic support through a matched CAMSHAFT BEARING PAIR and housing.

· Accurate timing via ground gears or calibrated chain/belt systems and tensioners.

· Vibration control using torsional dampers and balanced couplings.

· Optimized materials and heat treatments for high-load, high-temperature service.

· Tight tolerances and surface finishes that protect oil film integrity.

· Configurations adapted to diesel and gas engines in propulsion and power gen.

Technical function and performance impact of the CAMSHAFT BEARING PAIR

The CAMSHAFT BEARING PAIR is a hydrodynamic journal bearing set designed to hold the camshaft on its running axis. It creates a controlled clearance that supports oil-flow distribution, heat extraction, and load carrying. During operation, the bearing’s geometry produces an oil wedge that lifts the journal off the surface, minimizing metal-to-metal contact. This directly affects:

Performance: Stable cam phasing enhances volumetric efficiency and injector timing accuracy—key to power density and clean combustion in a diesel engine.

Efficiency: Reduced friction and minimized timing drift lower fuel consumption over long duty cycles.

Safety and reliability: Robust support limits the risk of cam seizure, tooth jump on chain drives, or gear pitting caused by misalignment.

Why engine drive components are crucial for reliability and service life

Engine drive components operate as a system; if one part drifts out of tolerance, the entire chain of precision is affected. Worn gears or elongated chains can induce timing errors, while misaligned housings or fatigued bearing overlays in the CAMSHAFT BEARING PAIR can lead to mixed or boundary lubrication, elevated temperatures, and rapid wear. Consequences include:

• Hard starting, loss of power, and higher fuel burn due to timing scatter.

• Increased vibration and noise, accelerating wear of sprockets, guides, and dampers.

• Oil contamination with metallic particles from distressed bearings, risking downstream component damage.

• In extreme cases, valve-to-piston contact or shutdown events that cause costly downtime.

Routine oil analysis, end-play checks, and borescope inspections help detect early signs of distress. Still, the most effective mitigation is specifying the correct components with verified dimensions, materials, and surface finishes tailored to the engine platform.

OEM spare parts for engine drive components: performance, reliability, budget, service life

Specifying OEM spare parts suitable for engine drive components—especially a CAMSHAFT BEARING PAIR OEM parts set—delivers measurable advantages:

· Exact geometry and clearances for the intended housing bore and cam journal.

· Proven material systems and overlays that match the engine’s load and oil chemistry.

· Consistent surface finishes for fast oil-film formation and low startup wear.

· Drop-in fit that reduces installation time and avoids costly adjustments.

· Traceable quality and batch consistency for predictable overhaul intervals.

· Lower total cost of ownership through longer service life and reduced unplanned stops.

Because the timing drive, camshaft, and bearing interfaces are tightly coupled, using parts produced to the same specification baseline preserves the designed relationships: gear mesh alignment, chain tension, and cam centerline position. This translates into stable emissions performance, smoother running, and reliable long-term operation in both marine and stationary applications.

MOPA: your partner for OEM parts for engine drive components

MOPA is an experienced and reliable partner for OEM spare parts for engine drive components, including the CAMSHAFT BEARING PAIR for diesel and gas engines. Customers benefit from fast response, assured quality, and secure handling of technical documentation and logistics. MOPA supports project schedules with short lead times, consolidated shipments, and careful packaging that protects precision surfaces. Transparent sourcing and product traceability add confidence when maintaining critical propulsion and power generation assets.

Conclusion: Engine drive components and CAMSHAFT BEARING PAIR

Engine drive components safeguard timing accuracy and mechanical stability, with the CAMSHAFT BEARING PAIR at the center of a durable, low-friction valve train. Selecting OEM spare parts suitable for this category protects performance, extends service life, and optimizes budgets by reducing downtime and repeat repairs. For dependable supply and expert support, MOPA delivers speed, quality, and security across diesel and gas engine fleets.