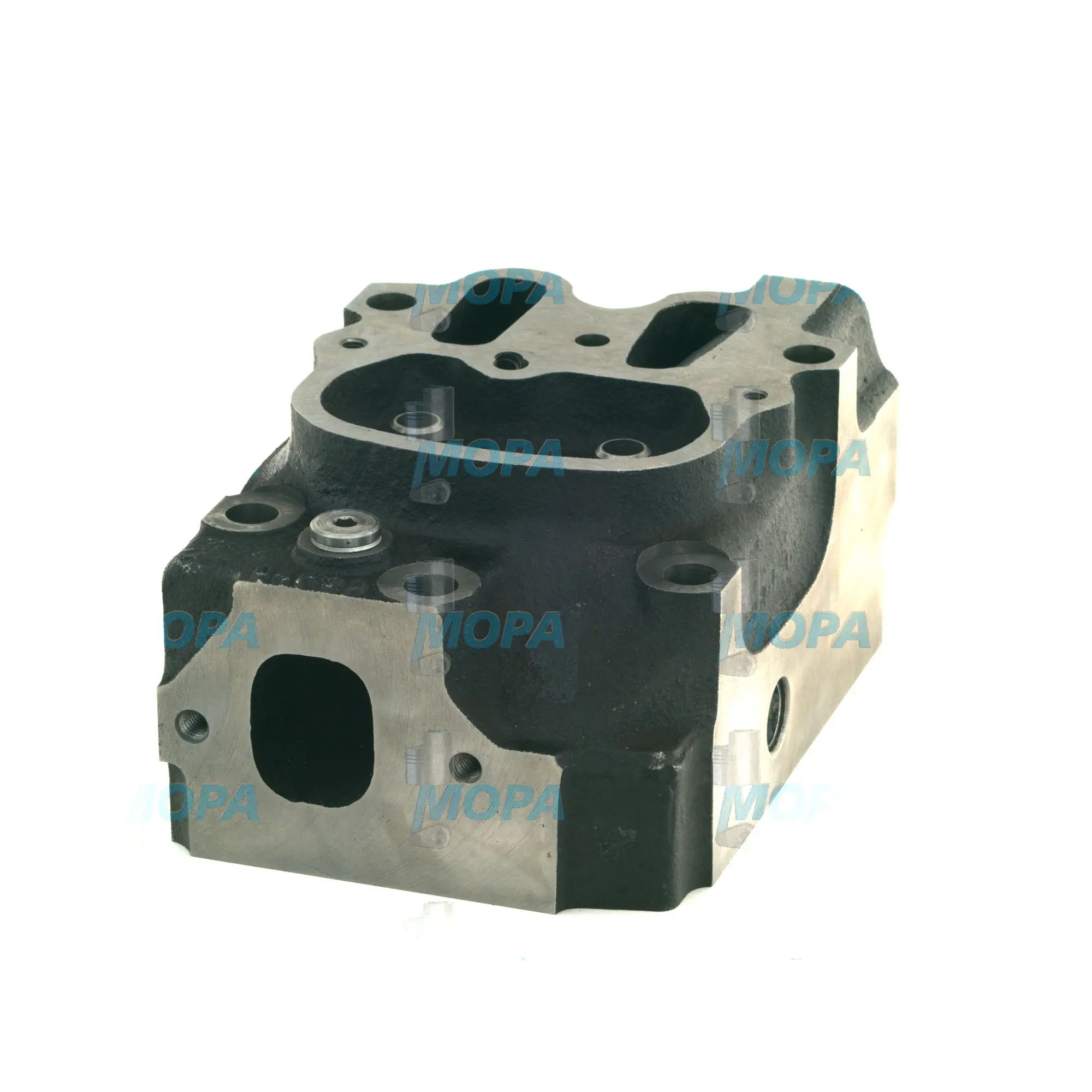

CYLINDER HEAD bare insights for Engine drive components in diesel and marine engines

Engine drive components form the mechanical backbone that transmits and times power inside every propulsion or power-generation unit. This article category covers the assemblies and subassemblies that convert combustion energy into usable torque and synchronize critical systems: crankshaft and camshaft drives, timing gears or chains, torsional vibration dampers, flywheels and housings, accessory drives, clutches and couplings, and related fasteners and seals. In practice, these components interact closely with the top end of the engine—especially the valvetrain mounted in the cylinder head—so even topics such as a CYLINDER HEAD bare marine engine configuration are relevant when evaluating drive design and maintenance.

For purchasers, shipowners, and technical decision-makers, specifying the right engine drive components is central to uptime and lifecycle cost. Precision-machined gears, aligned shafts, and calibrated dampers are what keep a diesel engine on timing, a generator set on frequency, and a propulsion line free of destructive vibration. Whether you manage blue-water vessels or stationary plants, a well-matched set of drive components—considering interfaces with a CYLINDER HEAD bare diesel engine top end—preserves performance, efficiency, and safety.

Engine drive components and CYLINDER HEAD bare function in diesel and marine engines

At the core, the crankshaft converts linear piston motion into rotation. The camshaft drive—via gear train, chain, or belt—translates that rotation into precisely phased valve events, coordinated with injection timing on mechanical fuel systems. Flywheels smooth cyclic torque to protect driveline equipment and improve idle stability. Torsional vibration dampers mitigate crankshaft torsion peaks that would otherwise cause gear rattle, bearing overload, and fatigue failures. Accessory drives power lube oil pumps, coolant pumps, and alternators, supporting thermal control and lubrication integrity under heavy loads.

Because valve timing accuracy is determined by the relationship between the drive train and the top end, the geometry and stiffness of a CYLINDER HEAD bare OEM parts configuration influence dynamic behavior. For example, rocker ratio, cam base circle, and follower design—mounted in or on the cylinder head—set the stiffness boundary conditions that the timing gear or chain must control. In a CYLINDER HEAD bare marine engine, long service intervals and extended low-load operation make timing stability, chain stretch resistance, and gear flank durability critical to clean combustion and low soot.

Key characteristics and advantages of Engine drive components

· High torsional stiffness for timing stability

· Precision gear profiles for low noise and wear

· Robust chain metallurgy and coatings against stretch

· Optimized damper tuning for specific firing orders

· Balanced flywheels for smooth torque delivery

· Corrosion-resistant materials for marine environments

· Thermal capacity to handle continuous-duty loads

· Exact fit-up with a CYLINDER HEAD bare diesel engine valvetrain

· Reliable sealing and fasteners to maintain alignment

· Proven compatibility with OEM parts documentation

Why Engine drive components are critical for reliability and service life

Every deviation in timing or alignment accumulates operational risk. Gear tooth pitting, chain elongation, or worn keyways cause phasing errors that lead to late or early valve events, poor combustion, fuel penalties, and rising exhaust temperatures. A mistuned or degraded torsional damper passes torque spikes into the crankshaft and cam drive, accelerating bearing wear and potentially causing shaft cracks. Flywheel imbalance propagates vibration through couplings and gearboxes, raising the likelihood of seal leaks and fastener loosening.

In marine applications, persistent humidity and salt exposure compound these issues by attacking unprotected gear flanks and couplings. When the top-end hardware is serviced—such as installing or machining a CYLINDER HEAD bare diesel engine assembly—any neglect in checking backlash, timing marks, and damper condition can undermine an otherwise high-quality overhaul. Ultimately, robust drive components preserve emissions compliance, protect safety systems (e.g., overspeed trips), and extend overhaul intervals.

Advantages of OEM spare parts suitable for Engine drive components and CYLINDER HEAD bare

Specifying OEM spare parts aligns materials, tolerances, and heat treatments with the engine maker’s design intent. This matters in high-load duty cycles where microscopic differences in hardness, surface finish, or tooth geometry determine whether gears run quietly for 30,000 hours or begin pitting after a season. The same logic applies at the interface with a CYLINDER HEAD bare marine engine: correct cam drive sprockets, chains, guides, and tensioners ensure precise valve motion and stable injection timing over the full service interval.

With OEM spare parts, purchasers gain consistent dimensional control for drop-in fit, validated metallurgy for fatigue resistance, and documented performance in diesel engine fleets. Lifecycle budgets benefit from predictable maintenance planning, fewer unplanned stoppages, and higher residual value of overhauled assets. Traceability and specification consistency also help operators meet class, safety, and emissions audits with minimal administrative friction.

CYLINDER HEAD bare OEM parts and drive interfaces in marine and diesel engines

Pairing a CYLINDER HEAD bare OEM parts set with correctly specified cam gears, chains, and dampers reduces lash growth, avoids rocker misalignment, and keeps valve acceleration profiles within design limits. The result is cleaner combustion, stable power density, and reduced NVH—outcomes that directly affect fuel spend and crew comfort.

MOPA: your partner for OEM spare parts Engine drive components

MOPA supplies OEM spare parts for engine drive components across leading diesel and gas engine platforms, serving marine and power-generation operators worldwide. Customers rely on our speed of delivery, consistent quality, and transactional security—from part identification and technical clarification to export documentation and global logistics. Whether you need a tuned torsional damper, a matched gear set, or timing components interfacing with a CYLINDER HEAD bare diesel engine, MOPA streamlines sourcing and reduces downtime risk.

Our team supports kitting for overhauls, cross-references by serial and BOM, and provides material and process traceability to help you maintain compliance and performance targets without disruption.

Conclusion: Engine drive components and CYLINDER HEAD bare alignment

Engine drive components safeguard timing precision, vibration control, and power transfer—cornerstones of reliable marine and diesel engine operation. Integrating these parts correctly with a CYLINDER HEAD bare configuration maximizes efficiency and protects critical hardware.

Choosing OEM spare parts suitable for engine drive components delivers consistent performance, longer service life, and budget certainty. With MOPA as your partner, you secure fast supply, proven quality, and confidence in every transaction.