OIL SPRAYER NOZZLE insights for Engine Drive Components

Engine drive components are the mechanical backbone that transmit torque from the crankshaft to camshafts, auxiliaries, and downstream equipment. This category covers timing gear trains and chains, belt drives, couplings, torsional vibration dampers, power take-offs, and accessory drives that keep cooling pumps, fuel pumps, alternators, and compressors synchronized with the engine’s operating cycle. In marine and stationary power applications, these parts must deliver precise timing, stable load transfer, and robust reliability under continuous duty and variable loads.

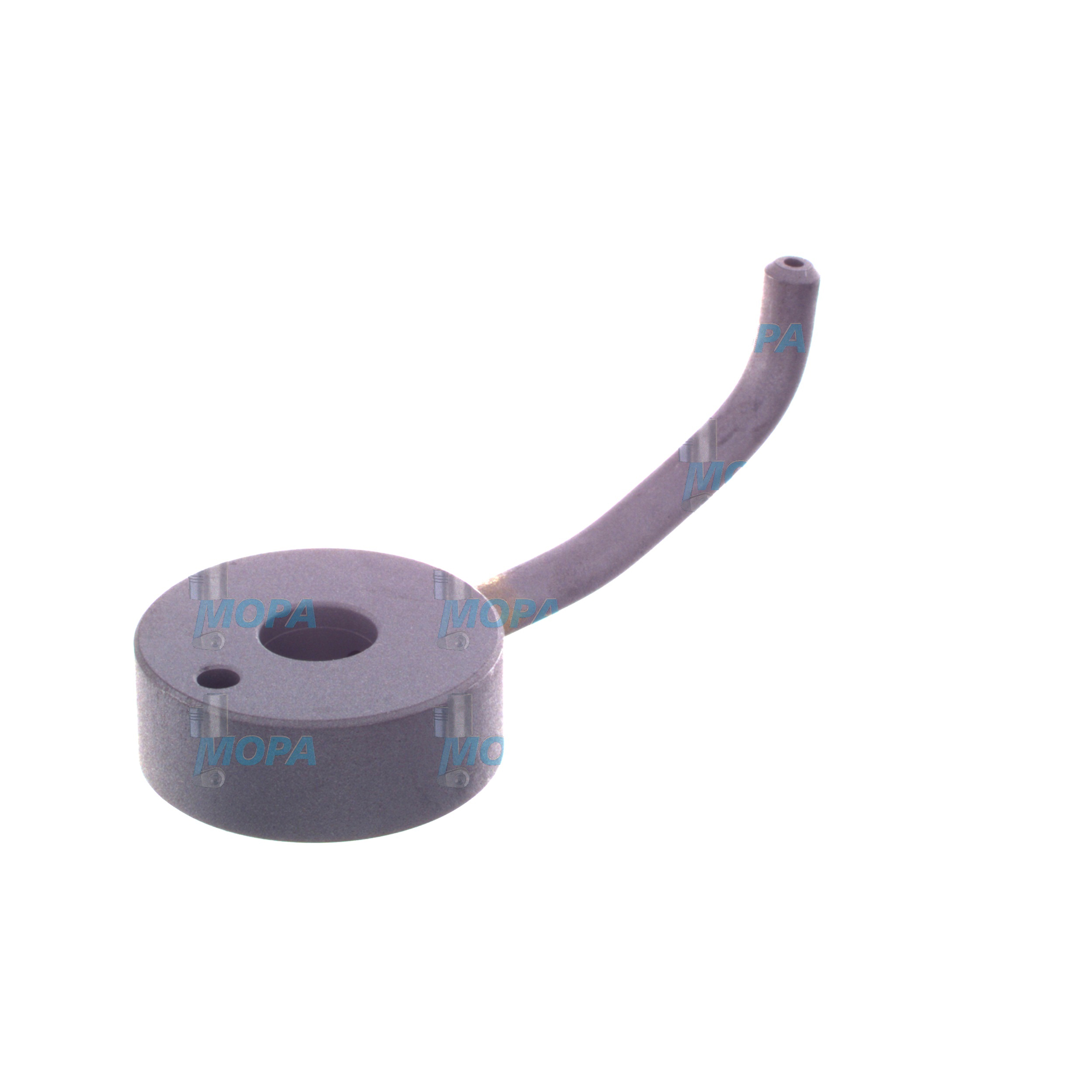

Because these interfaces run at high contact pressures and speeds, lubrication is decisive. The OIL SPRAYER NOZZLE plays a quiet but critical role by directing pressurized oil exactly where it is needed—onto timing chains, gear meshes, and often the piston underside—to build and maintain a protective film. In a diesel engine or a large marine engine, targeted oil jets reduce friction, flush wear particles, control temperature, and support the longevity of every drive element.

Technical function: Engine drive components with OIL SPRAYER NOZZLE performance in marine and diesel engines

Within an engine, drive components translate combustion power into synchronized motion. Gear trains couple the crankshaft to the camshaft with micrometer-accurate center distances and tooth profiles to preserve valve timing. Chains and belts transmit power to auxiliaries with controlled tension to minimize lash and vibration. Flexible and rigid couplings align shafts while accommodating misalignment and absorbing shocks. Torsional vibration dampers smooth crankshaft pulsations, protecting the gear case and accessory drive from fatigue.

Across these interfaces, the OIL SPRAYER NOZZLE ensures tribological stability. Fed by the lube circuit, it meters flow through calibrated orifices and sprays conical or fan-shaped jets onto chain links, sprocket flanks, and gear teeth. This creates an oil film that prevents metal-to-metal contact, reduces local temperature spikes, and carries away debris. In a diesel engine with high brake mean effective pressure, the nozzle’s placement and angle are engineered so oil reaches the load zone precisely when and where contact occurs. In a marine engine gear case, multiple OIL SPRAYER NOZZLE positions may be used to cover primary and idler meshes for consistent film strength during variable RPM and load steps. When selected as OEM parts, nozzle flow characteristics match the engine builder’s lubrication map, ensuring optimal distribution at idle and full load.

- · Precise torque transmission under continuous duty.

- · Stable valve timing via gears or chains with controlled backlash.

- · Effective auxiliary drive for pumps, alternators, and compressors.

- · Vibration damping to protect shafts and bearings.

- · Targeted lubrication from the OIL SPRAYER NOZZLE to reduce wear.

- · Lower friction and temperature for improved efficiency.

- · Designed clearances and materials for long service life.

Importance for engine operation: Reliability, uptime, and safety

Healthy engine drive components are foundational to safe operation and lifecycle economics. If gear teeth pit or chain links elongate, valve timing drifts and combustion quality suffers, raising fuel consumption and emissions. Excessive backlash can trigger vibration that propagates through bearings and housings, accelerating fatigue. A slipping belt or degraded coupling can starve critical auxiliaries—coolant flow falls, charge air temperature rises, and alarms follow. In propulsion, this cascade risks loss of thrust or blackouts.

The status of the OIL SPRAYER NOZZLE directly influences these risks. A partially clogged nozzle reduces film thickness on high-load flanks, increasing scuffing and heat. Misaligned jets can leave dry zones on chains, promoting rapid elongation and sprocket wear. In severe cases, insufficient piston underside cooling leads to skirt scuffing or oil coking. Routine monitoring of oil cleanliness, nozzle condition, and correct jet orientation is therefore vital to keep drive components within their design envelope—especially in large marine engine installations where load cycles are demanding and downtime is costly.

Typical problems when components or nozzles are out of spec

Common failure indicators include rising vibration at gear mesh frequencies, chain noise (“whine”) during transients, hot-running belt drives, and recurrent auxiliary pump trips. These symptoms often trace back to wear, incorrect clearances, or inadequate lubrication. Addressing the root cause with correctly engineered replacements—gears with validated microgeometry, tensioners with specified damping, and an OIL SPRAYER NOZZLE with the proper orifice and spray pattern—restores performance and extends overhaul intervals.

Advantages of OEM spare parts suitable for Engine drive components

Choosing OEM spare parts suitable for engine drive components preserves the engineered balance of materials, tolerances, and lubrication dynamics.

Key benefits include:

Performance: Tooth profiles, surface hardness, and chain pin metallurgy are matched to the engine’s torque and speed spectrum. The OIL SPRAYER NOZZLE flow rate and cone angle align with the lubrication schematic, sustaining the hydrodynamic film at idle and rated RPM.

Reliability: Dimensional accuracy ensures correct backlash, center distance, and shaft alignment. Validated seals and dampers keep contamination and torsional peaks in check, while calibrated nozzles maintain consistent oil delivery across temperature and viscosity changes.

Budget: Drop-in fit reduces installation time, rework, and collateral damage risk. Stable lubrication lowers frictional losses and heat, cutting fuel consumption and protecting expensive downstream parts.

Service life: Certified materials and heat treatments resist pitting, fretting, and elongation. With the right OIL SPRAYER NOZZLE OEM parts, spray targeting and flow stability support longer inspection intervals and predictable maintenance planning.

MOPA: OEM parts for Engine Drive Components and OIL SPRAYER NOZZLE supply

MOPA is an experienced partner for sourcing OEM spare parts suitable for Engine drive components, including gears, chains, couplings, tensioners, dampers, and every related OIL SPRAYER NOZZLE. Our team combines technical expertise with agile logistics to deliver speed, quality, and security in the trade of OEM parts for diesel and gas engines. We provide accurate cross-referencing, documentation, and batch traceability, and we ship worldwide to shipyards, fleet operators, and power plants on tight schedules.

Whether you need a camshaft gear set for a medium-speed marine engine, a calibrated OIL SPRAYER NOZZLE for a high-speed diesel engine, or a matched kit of tensioners and belts for auxiliary drives, MOPA helps you minimize downtime and maintain compliance with class and safety requirements.

Conclusion

Engine drive components determine how efficiently and reliably an engine converts combustion power into synchronized motion. Targeted lubrication from the OIL SPRAYER NOZZLE protects these interfaces, stabilizes temperatures, and reduces wear. Selecting OEM spare parts suitable for Engine drive components—including the correct OIL SPRAYER NOZZLE—delivers dependable performance, predictable costs, and longer service life across marine and industrial applications.