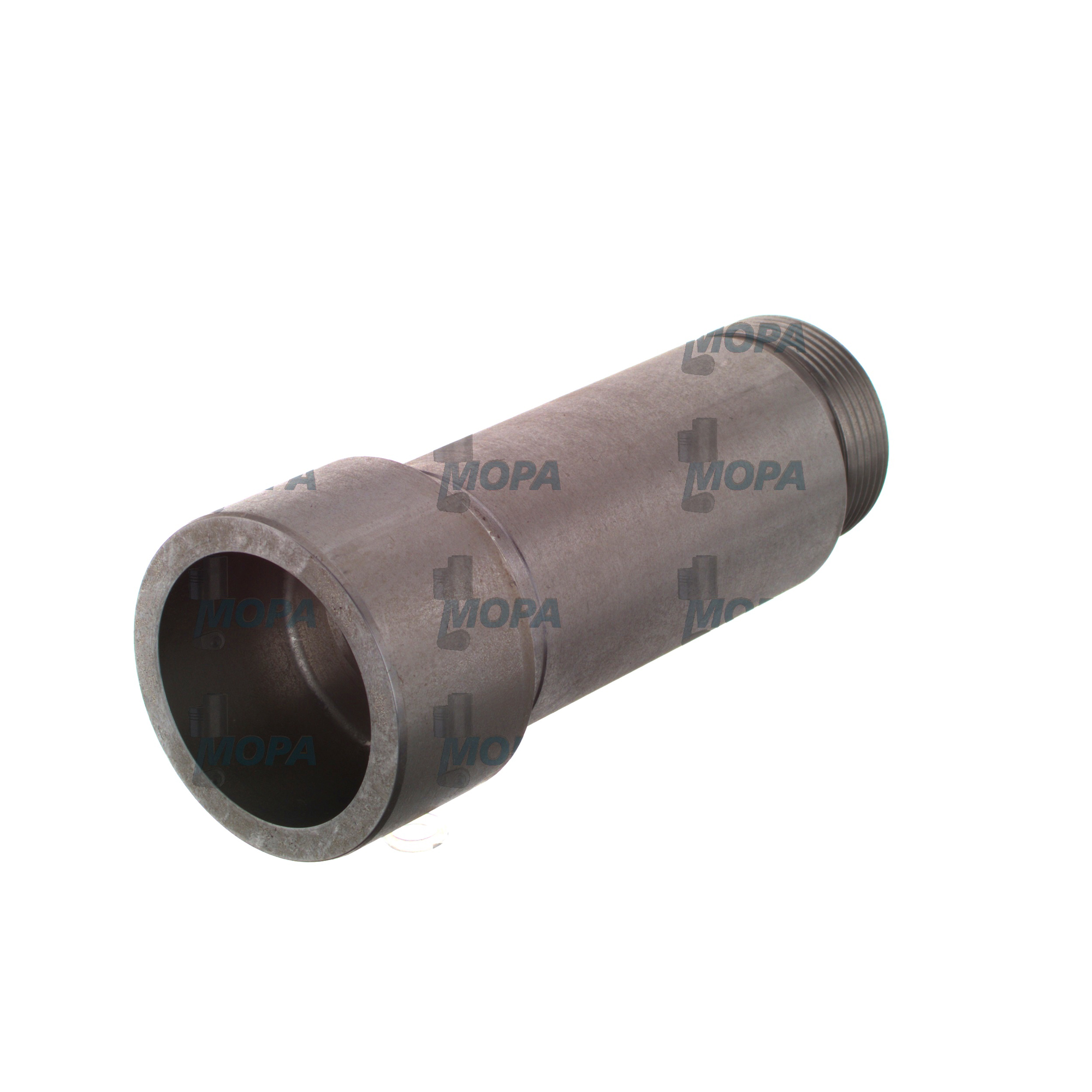

PRE-CHAMBER TOP Engine Drive Components for diesel and gas engines

Engine drive components form the mechanical backbone that transmits power from the crankshaft to camshafts, injection pumps, auxiliaries, and the propulsion or generator set. As a category, these parts include gear trains, timing chains, belt drives, flexible couplings, power take-offs (PTO), torsional vibration dampers, and alignment hardware. They ensure precise timing, efficient torque transfer, and safe operation under continuous load. In heavy-duty contexts—such as a marine engine or an industrial diesel engine—the integrity of this drive system directly shapes fuel efficiency, emissions stability, and uptime. Even combustion hardware choices, like a PRE-CHAMBER TOP diesel engine configuration, place specific demands on drive timing accuracy and vibration control, underscoring the importance of robust, correctly specified engine drive components.

Technical function of engine drive components in diesel and marine engines — PRE-CHAMBER TOP context

Engine drive components synchronize and distribute torque with high precision. Gear trains or chains link the crankshaft to the camshaft and fuel injection equipment so that valve events and injection timing align with piston motion. In a PRE-CHAMBER TOP marine engine or generator set, finely controlled timing is critical for stable ignition and uniform combustion in the pre-chamber and main chamber. Any drift in timing or torsional irregularity can compromise ignition delay and mixture formation, affecting power balance and emissions.

Beyond timing, the drive system powers essential auxiliaries: lube oil pumps, coolant pumps, charge-air blowers, high-pressure fuel pumps, and alternators. Couplings and PTOs transfer torque to downstream equipment while accommodating misalignment, axial growth, and shock loads. Torsional vibration dampers mitigate resonance peaks, protecting shafts, keys, and gear teeth from fatigue. Materials and surface treatments—carburized gears, nitrided shafts, and shot-peened sprockets—are selected to resist pitting, scuffing, and fretting under boundary lubrication and cyclic load.

The engineering targets are clear: minimal backlash, controlled chain elongation, accurate tooth geometry, correct hardness depth, and dynamic balance of rotating elements. These factors preserve timing integrity and protect the combustion process—especially relevant for PRE-CHAMBER TOP OEM parts packages where valve train and injection synchronization must remain within tight tolerances over long service intervals.

- · Precise timing control for camshaft and injection equipment.

- · Reliable torque transfer to pumps, blowers, and alternators.

- · Torsional vibration damping to prevent fatigue failures.

- · Materials engineered for pitting, scuffing, and wear resistance.

- · Alignment and coupling design to handle thermal growth and shock loads.

- · Low backlash and controlled elongation for stable long-term operation.

Why engine drive components are critical for reliability and service life

Healthy engine drive components safeguard the core timing and torque path of a diesel engine. If gears wear or chains elongate, valve and injection timing drift, leading to rough running, higher fuel consumption, and increased exhaust temperatures. In marine propulsion or onboard power, this can escalate to loss of power, black smoke, and non-compliance with emissions requirements. Damaged couplings or misaligned PTOs transmit harmful loads that accelerate bearing wear and cause seal failures, oil leaks, and even shaft fractures. A fatigued torsional vibration damper allows resonance amplification, which can crack keyways, loosen fasteners, and damage gear teeth.

Other risk patterns include tooth pitting from insufficient lubrication, fretting at spline interfaces, and corrosion in salty environments. In severe cases, a sudden drive failure can result in loss of lube oil pressure or coolant circulation—events that can rapidly cause overheating, bearing damage, or an engine shutdown at sea. For applications using a PRE-CHAMBER TOP diesel engine, the penalty for timing instability is stark: non-uniform ignition across cylinders, increased peak pressures, and accelerated wear on valves and injectors. Consistent, specification-true drive components are therefore central to uptime and total cost of ownership.

Advantages of OEM spare parts suitable for engine drive components

Selecting OEM spare parts suitable for engine drive components preserves engineered tolerances and material properties that generic replacements often miss. Tooth profiles, chain pitch accuracy, heat treatment depth, and damper tuning are calibrated to the engine’s torsional signature and expected load spectrum. This means easier installation, faster commissioning, and stable timing for the full service interval. For systems where a PRE-CHAMBER TOP OEM parts set is specified, matched geometry and hardness across gears, sprockets, and shafts help maintain combustion consistency and reduce noise and vibration.

Traceable metallurgy and proven surface finishes yield predictable wear behavior, while factory balancing of rotating parts reduces bearing loads and energy losses. The result is better performance, higher reliability, and controlled lifecycle costs—benefits that outweigh short-term savings from ill-matched components. In marine engine and power generation fleets, standardized OEM parts also simplify inventory planning and reduce downtime.

- · Exact fit and clearances preserve timing accuracy.

- · Verified materials and heat treatment resist pitting and fatigue.

- · Factory-balanced rotating parts reduce vibration and bearing wear.

- · Correct damper tuning protects against torsional resonance.

- · Consistent quality improves uptime and lowers maintenance spend.

- · Compatibility with PRE-CHAMBER TOP OEM parts supports clean combustion.

MOPA — fast, secure supply of OEM engine drive components

MOPA is an experienced and reliable partner for OEM spare parts suitable for engine drive components. Clients in shipping, power generation, and industry rely on our speed, quality, and security in the trade of OEM parts for diesel and gas engines. We help identify the right gear sets, chains, couplings, dampers, PTO components, and alignment kits—cross-referenced by engine model and application, including PRE-CHAMBER TOP diesel engine configurations for marine engine and land-based units. With streamlined logistics and documentation, MOPA supports planned maintenance and urgent repairs alike, reducing lead times and operational risk.

Conclusion: Engine drive components and PRE-CHAMBER TOP performance

Engine drive components are foundational to timing precision, torque transfer, and vibration control—key enablers of safe, efficient operation in diesel and gas engines. In applications that incorporate a PRE-CHAMBER TOP setup, stable drive dynamics directly support clean combustion and consistent output.

Choosing OEM spare parts suitable for engine drive components protects performance, reliability, budget, and service life. With MOPA as a trusted supply partner, fleets achieve fast, secure access to the right components—keeping assets productive and compliant.