THRUST BEARING PAIR for Engine Drive Components

Engine drive components form the backbone of power transmission in heavy-duty diesel, gas, and marine engines. They channel torque from the crankshaft to the drivetrain, manage loads, preserve alignment, and stabilize rotating assemblies under demanding operating conditions. Within this category, the THRUST BEARING PAIR is a critical element: it absorbs axial (end-thrust) forces, protects the crankshaft and block, and ensures precise axial positioning for smooth and efficient operation. For shipowners, plant operators, and procurement teams, understanding how these components function—and why specifying the right parts matters—directly impacts uptime, lifecycle cost, and safety.

Technical function of a THRUST BEARING PAIR in diesel and marine engine drive components

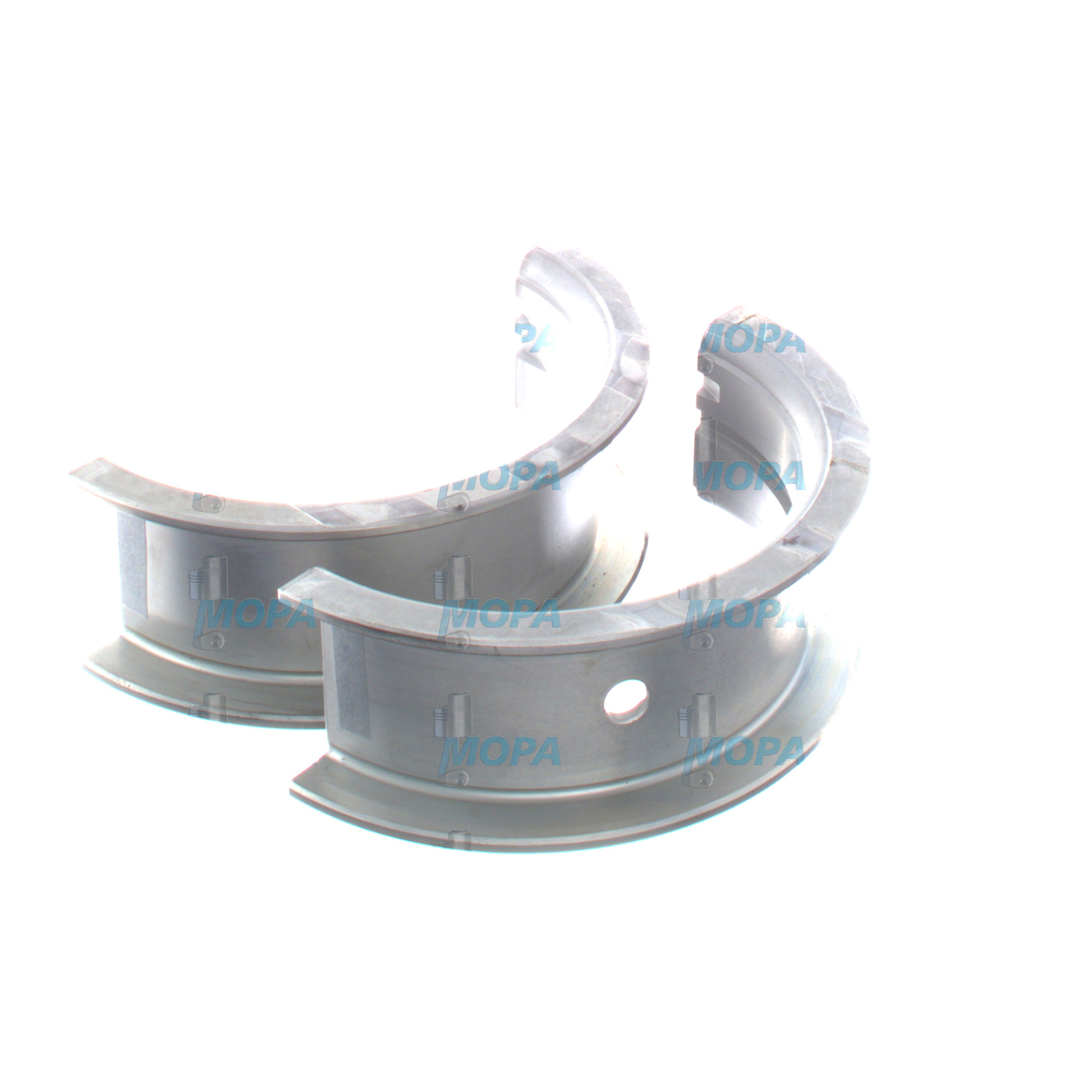

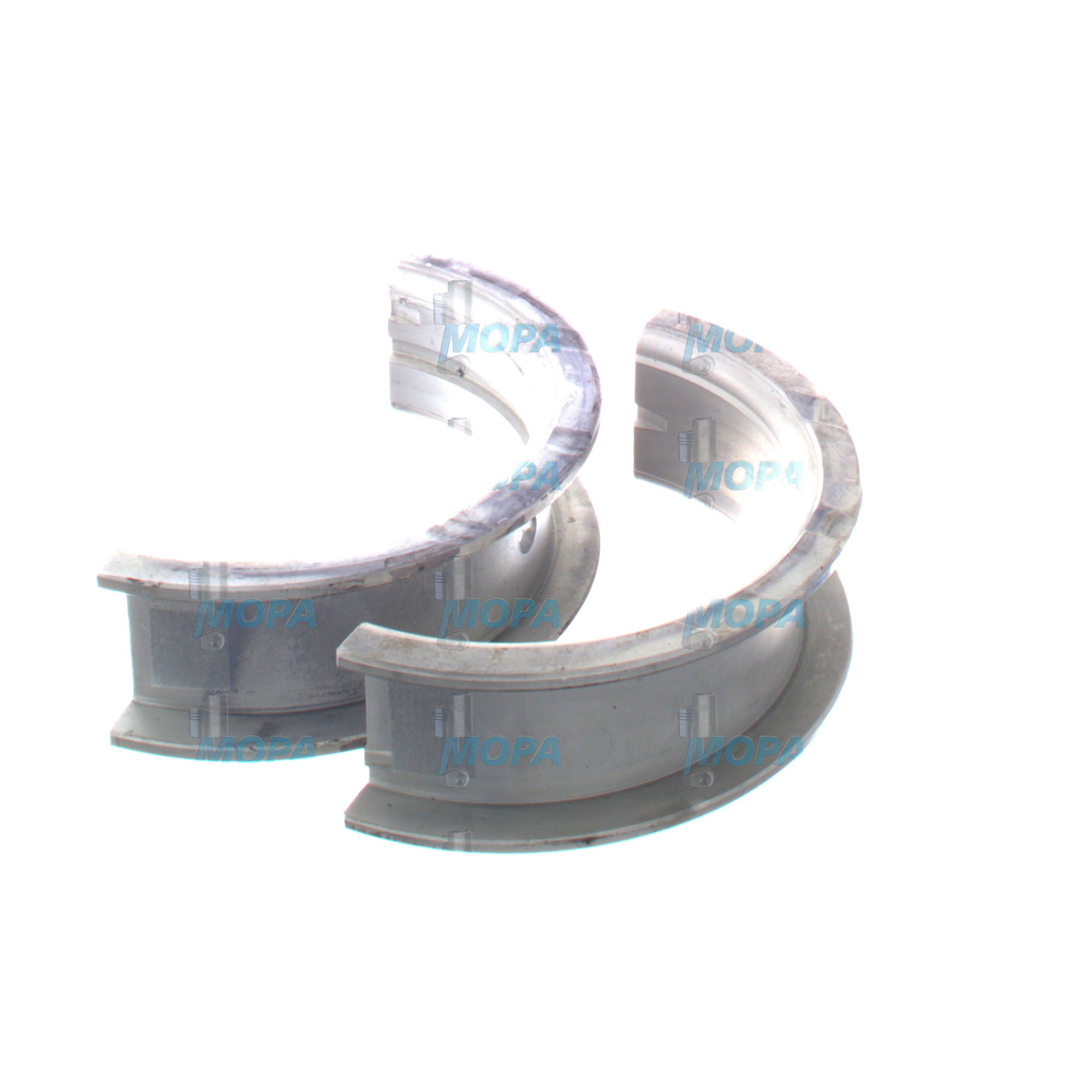

A THRUST BEARING PAIR typically consists of two half-rings or flanged bearing elements that seat against the crankshaft thrust faces at a designated main bearing location. In a diesel engine or marine engine, axial loads are generated by the propeller push, gear mesh forces, and the dynamics of couplings and accessories. The THRUST BEARING PAIR converts this axial load into a controlled, hydrodynamically lubricated contact area, maintaining the correct crankshaft endplay while preventing metal-to-metal contact.

Under normal conditions, engine oil forms a protective film between the bearing surface and the crankshaft. Precisely machined oil grooves and the geometry of the THRUST BEARING PAIR create hydrodynamic wedge effects that carry axial loads at operating speed. The result is stable axial positioning of the crankshaft, consistent timing gear alignment, reduced frictional heat, and lower wear across the entire drive line. In high-torque applications, such as a marine engine pushing a fixed-pitch propeller, the thrust load is continuous; correct bearing specification and clearance are therefore indispensable for performance and efficiency.

How a THRUST BEARING PAIR supports performance, efficiency, and safety

When fitted and lubricated correctly, the THRUST BEARING PAIR keeps endplay within OEM specifications, which helps:

- · Maintain gear train alignment for accurate timing and injection events.

- · Reduce vibration and noise, especially in long shaft lines and reduction gears.

- · Protect seals, couplings, and main bearings from axial overloading.

- · Improve efficiency by minimizing parasitic losses in boundary conditions.

- · Safeguard the crankshaft against axial scoring and thermal distress.

Material selection—such as tri-metal overlays, copper-lead intermediate layers, or aluminum-tin systems—must match the duty cycle, oil chemistry, and temperature profile of the engine. Correct pairing with OEM parts ensures the surface finish, hardness, and overlay thickness needed to sustain oil film integrity during load spikes, cold starts, and slow-speed maneuvers.

Key characteristics and advantages of Engine Drive Components

- · Precise axial and radial load management for long engine life.

- · High dimensional accuracy to preserve alignment and reduce wear.

- · Optimized lubrication paths for stable oil film formation.

- · Robust materials engineered for heavy-duty diesel and marine cycles.

- · Compatibility with OEM parts for predictable fit and performance.

- · Reduced vibration and noise across the drive train.

- · Lower lifecycle costs through extended service intervals.

Why engine reliability depends on a THRUST BEARING PAIR

Engine reliability is tightly coupled to axial control. Excessive endplay can cause timing gear misalignment, accelerated gear tooth wear, and camshaft drive instability. In severe cases, the crankshaft can “walk,” damaging thrust faces, upsetting the oil film, and contaminating the lubrication system with metal debris. On marine propulsion sets, improper thrust control may also transfer load into couplings and gearbox bearings, leading to overheating, seal damage, and unplanned downtime offshore. In power generation, poor axial control can trigger vibration alarms, cause sensor misreads, and shorten the life of couplings and main bearings.

Routine inspection of endplay, oil analysis for lead/tin/copper content, and visual checks for overlay wiping or fretting are practical measures to prevent costly failures. When the THRUST BEARING PAIR shows wear, timely replacement restores axial control, protects the crankshaft, and returns the engine drive components to optimal condition.

Advantages of OEM spare parts suitable for Engine Drive Components

Selecting OEM spare parts suitable for a THRUST BEARING PAIR and related engine drive components delivers measurable benefits for performance, reliability, budget, and service life:

- · Engineered metallurgy and overlay thickness tailored to load spectra.

- · Tight tolerances for endplay, width, and crush to ensure correct fit.

- · Verified oil groove geometry for consistent hydrodynamic support.

- · Proven compatibility with mating surfaces and housings.

- · Stable performance across diesel engine and gas engine applications.

- · Lower total cost of ownership through predictable overhaul intervals.

- · Traceability and documentation that support compliance and audits.

By using OEM spare parts matched to your engine model, you secure controlled clearances, reliable oil film behavior, and repeatable installation outcomes—key factors for safeguarding high-value assets and avoiding cascading failures in the drive line.

MOPA — reliable partner for OEM spare parts THRUST BEARING PAIR

MOPA is an experienced, dependable partner for sourcing OEM spare parts for engine drive components, including the THRUST BEARING PAIR for diesel and gas engines. We combine speed, quality, and security in the trade of OEM parts, ensuring quick quotations, fast shipping, and verified part matching against engine serials and build lists. Our team supports purchasers and technical managers with cross-references, documentation, and logistics solutions that minimize downtime—whether you operate a marine engine fleet or land-based power units.

From urgent replacements to planned maintenance kits, MOPA streamlines procurement with transparent lead times, careful packaging, and robust supply chain controls that protect both component integrity and your schedule.

Conclusion

A THRUST BEARING PAIR is fundamental to the stability and longevity of engine drive components, keeping axial loads under control and protecting the crankshaft, gears, and couplings. Specifying OEM spare parts suitable for this application ensures precise fit, consistent lubrication performance, and dependable service life—benefits that translate directly into uptime and lower operating costs.